A kind of foam concrete and its application in the production of lightweight waterproof strips

A foamed concrete and lightweight technology, applied in the field of building materials, can solve the problems of low flexural strength, durability, cracks in foamed concrete, etc., and achieve the effects of strong flexural damage resistance, simple production process and good impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

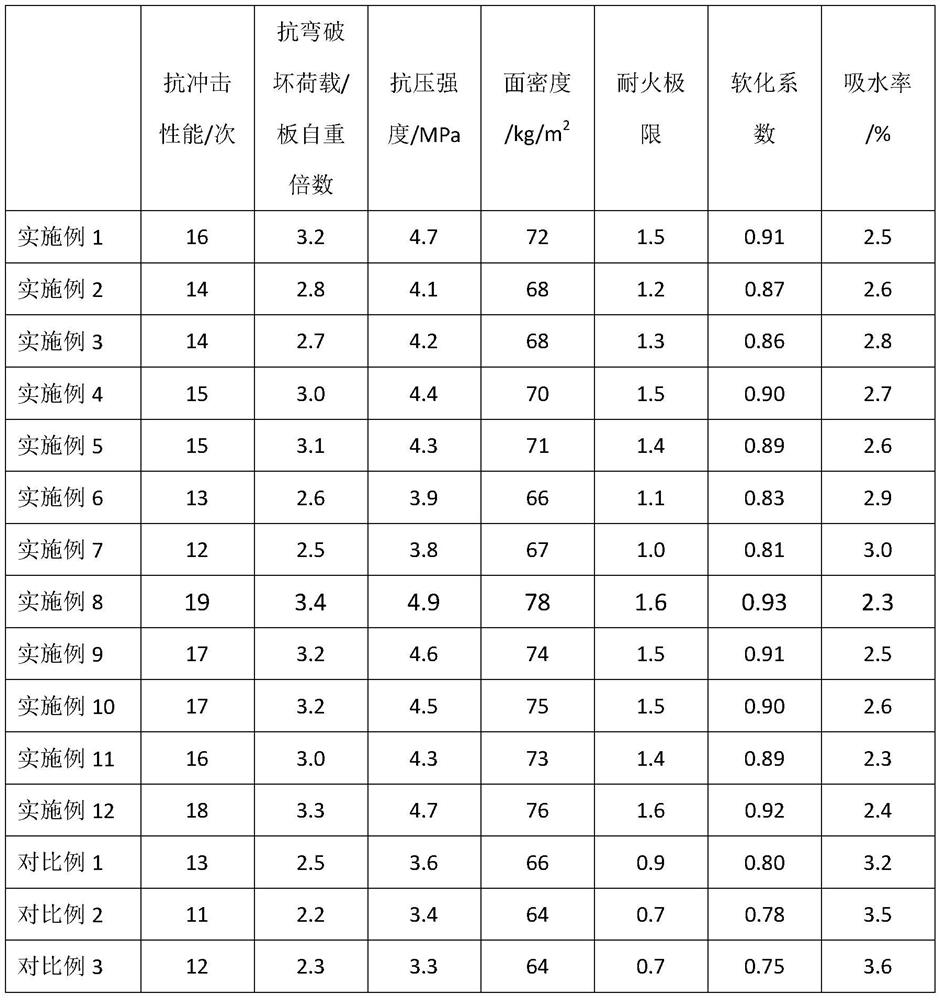

Examples

Embodiment 1

[0045] A foam concrete, the raw material formula is composed of the following components in parts by weight: 40 parts of cement, 3 parts of composite waterproofing agent, 2 parts of water reducing agent, 12 parts of fly ash, 3.5 parts of foaming agent, 2.5 parts of latex powder , 9 parts of fine sand, 28 parts of water.

[0046] Wherein, the foaming agent is fatty alcohol polyoxyethylene ether sodium sulfate and silicone resin polyether emulsion, and its mass ratio is 2:1, and the composite waterproofing agent used is calcium stearate and sodium methyl silicate, and its mass ratio 1:1.

[0047] There are two fiber mesh cloths in step S1, specifically polyester fiber mesh; the foam concrete layer made of the above-mentioned foam concrete is arranged in the middle.

Embodiment 2

[0049]A kind of foam concrete, the raw material formula is made up of each component of following parts by weight: 40 parts of cement, 5 parts of composite waterproofing agent, 2 parts of water reducer, 12 parts of fly ash, 3.5 parts of foaming agent, 2.5 parts of latex powder , 9 parts of fine sand, 26 parts of water. 100

[0050] Others are with embodiment 1.

Embodiment 3

[0052] A foam concrete, the raw material formula is composed of the following components in parts by weight: 40 parts of cement, 1 part of composite waterproofing agent, 2 parts of water reducing agent, 12 parts of fly ash, 3.5 parts of foaming agent, and 2.5 parts of latex powder , 9 parts of fine sand, 30 parts of water. 100

[0053] Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com