A kind of preparation method of oxytetracycline hydrochloride

A technology of oxytetracycline hydrochloride and oxytetracycline hydrochloride, which is applied in the field of preparation of oxytetracycline hydrochloride, can solve the problems of insufficient utilization of cosolvent and hydrochloric acid methanol, increased methanol consumption, and high methanol consumption, so as to reduce the amount of solid waste, The effect of reducing production costs and reducing the number of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A kind of preparation method of oxytetracycline hydrochloride of the present invention, it comprises the steps:

[0024] One, get raw material oxytetracycline and ethanol and put into the first reactor in proportion (kg / L) 1:3.5, after heating up and distilling for a period of time, cool to room temperature, then the material in the first reactor is centrifuged through centrifuge, Obtain oxytetracycline wet product with water content lower than 0.1%;

[0025] 2. Put calcium chloride and methanol into the second reaction kettle, stir and dissolve to obtain a calcium chloride methanol solution, then add the wet product of oxytetracycline in step 1 to the second reaction kettle, stir, slightly heat, until all After dissolving, add a small amount of activated carbon, stir, and filter to obtain oxytetracycline methanol solution. After the oxytetracycline methanol solution is cooled, add hydrogen chloride methanol solution, stir and crystallize, cool, filter, and wash the fil...

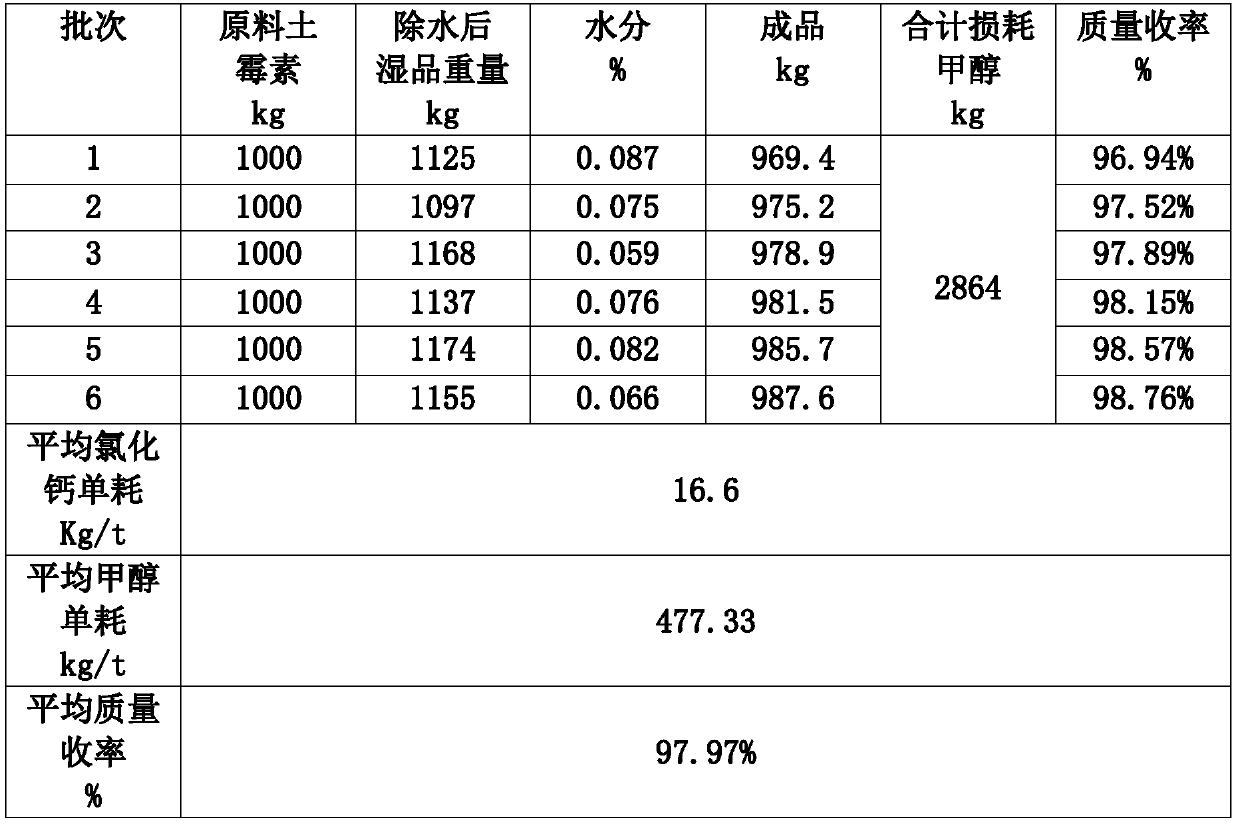

Embodiment 1

[0038] (1) get raw material oxytetracycline 1000kg, ethanol 4000L is sent in the first reaction kettle, ethanol is distilled out about 2000L by heating, is cooled to room temperature, centrifuges, obtains the oxytetracycline alkali wet product that water content is lower than 0.1%.

[0039] (2) Take the wet product of oxytetracycline from step (1), 4000L of methanol, and 100kg of calcium chloride, put them into the second reaction kettle sink, stir and dissolve at about 30°C until clarified, add 15kg of activated carbon, continue to stir for 10 minutes, filter, and the filtrate Use methanol equivalent to 76kg of hydrogen chloride to form a salt, cool the system to ≤0°C, centrifuge, and dry to obtain a finished product, and transport the mother liquor to a liquid storage tank.

[0040] (3) Take the wet product of oxytetracycline in step (1), put 4000L of mother liquor into the second reaction kettle, stir and dissolve at about 30°C until clarified, add 15kg of activated carbon, ...

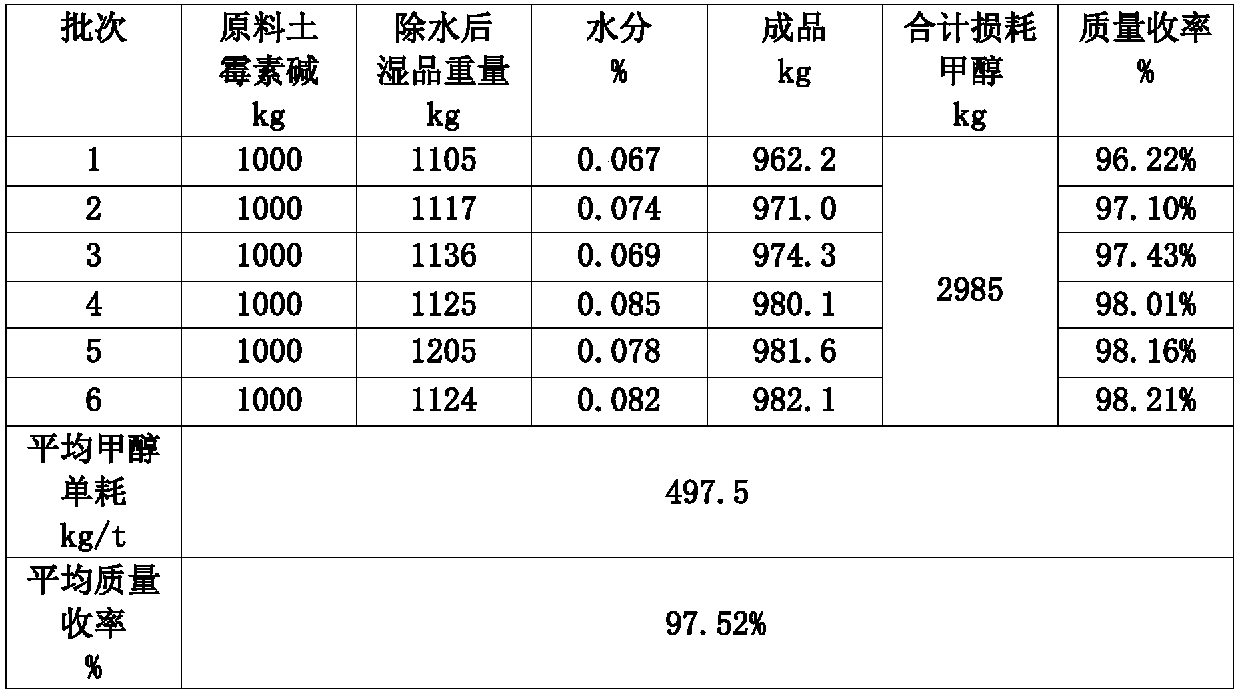

Embodiment 2

[0046] (1) get raw material oxytetracycline 1000kg, ethanol 4000L is sent in the first reaction kettle, ethanol is distilled out about 2000L by heating, is cooled to room temperature, centrifuges, obtains the oxytetracycline alkali wet product that water content is lower than 0.1%.

[0047] (2) Take the wet product of oxytetracycline in step (1), 4000L of methanol, hydrochloric acid methanol equivalent to 35kg of hydrogen chloride, put it into the second reaction kettle sink, stir and dissolve at about 30°C until clear, add 15kg of activated carbon, continue to stir for 10 minutes, and filter , the filtrate is salted with methanol hydrochloric acid equivalent to 41kg of hydrogen chloride, the temperature of the system is lowered to ≤0°C, centrifuged, and dried to obtain the finished product, and the mother liquor is transported to the liquid storage tank.

[0048](3) Take the wet product of oxytetracycline in step (1), put 4000L of mother liquor into the second reaction kettle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com