Quaternization cellulose bead as well as preparation method and application thereof

A technology of cellulose beads and quaternization, applied in the field of preparation and quaternization of cellulose beads, can solve problems such as modification of cellulose beads, and achieve the effects of good repeatability, high reaction efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

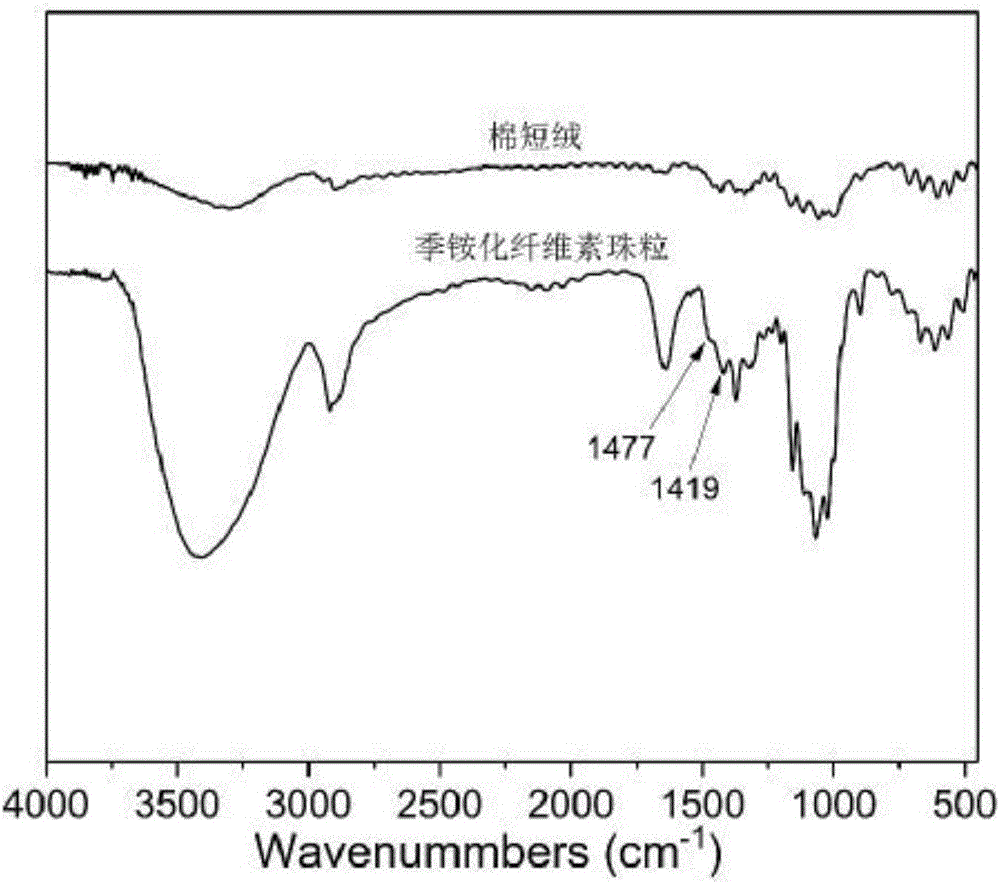

[0038] Prepare quaternized cellulose beads, the specific steps are as follows: 1) Prepare quaternized cellulose solution: 200g NaOH / urea aqueous solution (the mass ratio of NaOH, urea and water is 7:12:81) is pre-cooled to -12°C Finally, 6 g of cellulose was dissolved, and 5.611 g of 2,3-epoxypropyltrimethylammonium chloride was added. After centrifugal defoaming and impurity removal, the mixture was placed at 25° C. for 24 hours for homogeneous reaction to obtain a quaternized cellulose solution.

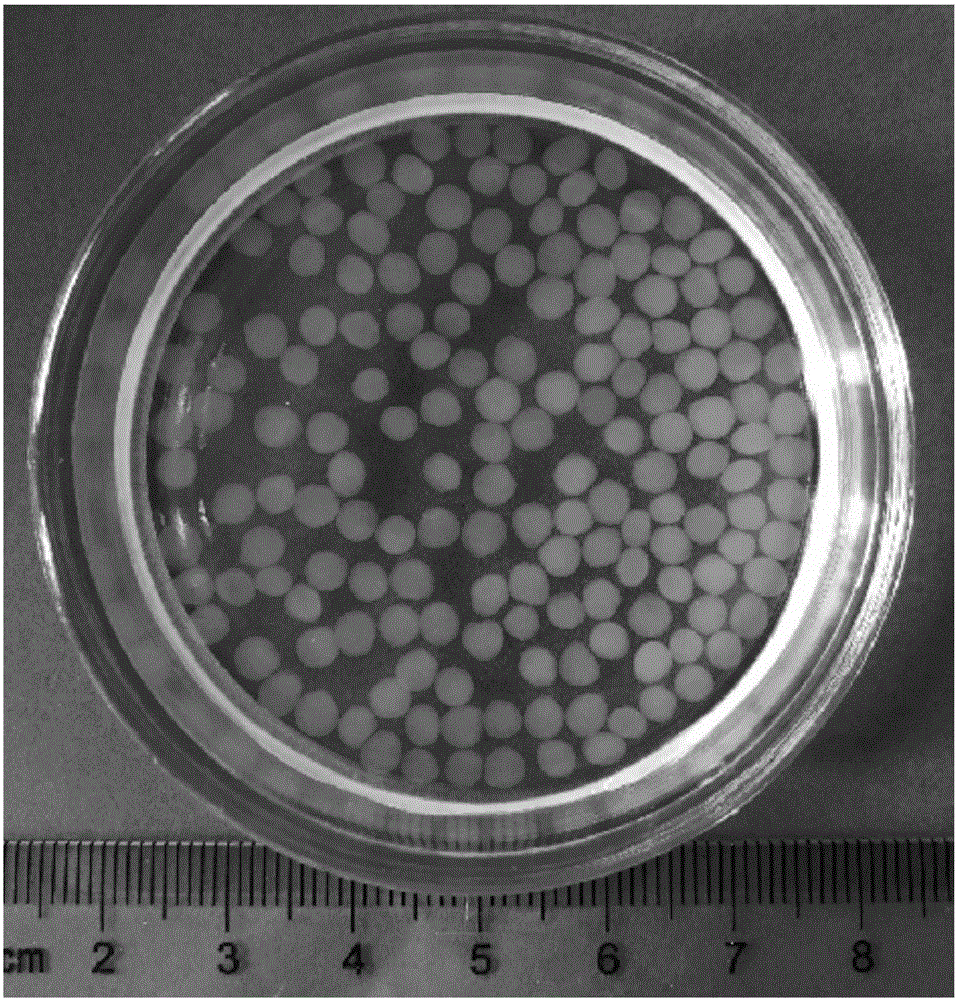

[0039]2) Preparation of quaternized cellulose beads: the quaternized cellulose solution prepared in step 1) is squeezed through a 0.8mm needle syringe, and dripped to a mass fraction of 10% at a position 10 cm above the solidified liquid level solidified in an aqueous solution of sodium chloride, and washed with distilled water to remove impurities to obtain quaternized cellulose beads.

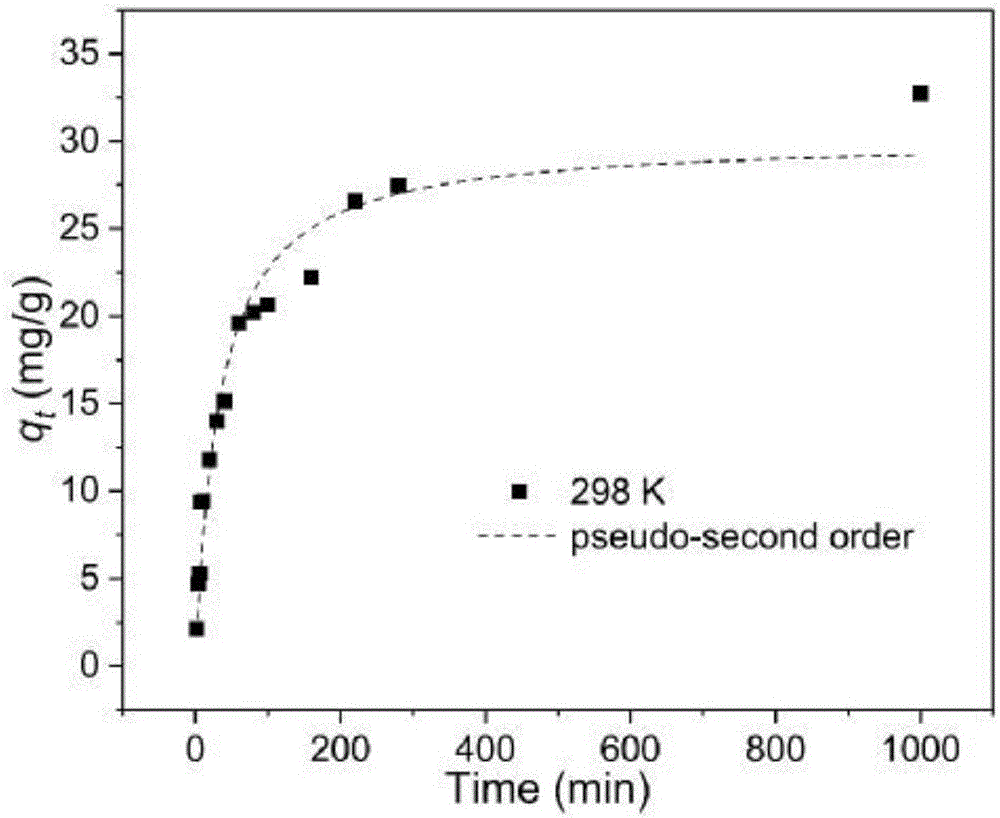

[0040] The water content of the quaternized cellulose beads prepared in this embodiment is 97%...

Embodiment 2

[0046] Prepare quaternized cellulose beads, the specific steps are as follows:

[0047] 1) Preparation of quaternized cellulose solution: Pre-cool 200g of NaOH / urea aqueous solution (the mass ratio of NaOH, urea and water is 7:12:81) to -5°C and dissolve 6g of cellulose, add 0.561g of 2,3 -Glycidyltrimethylammonium chloride, after centrifugal defoaming and impurity removal, place at 4°C for 1 hour for homogeneous reaction to obtain a quaternized cellulose solution.

[0048] 2) Preparation of quaternized cellulose beads: the quaternized cellulose solution obtained in step 1) is extruded through a 0.45mm needle syringe, and dripped into pure water for solidification at a height of 3 cm from the solidification liquid level. Impurities were removed by washing with distilled water to obtain quaternized cellulose beads.

[0049] After measurement, the particle diameter of the quaternized cellulose beads prepared in this example is 1 mm, the water content is 95%, and the skeleton de...

Embodiment 3

[0051] Prepare quaternized cellulose beads, the specific steps are as follows:

[0052] 1) Preparation of quaternized cellulose solution: pre-cool 200g NaOH / urea aqueous solution (the mass ratio of NaOH, urea and water is 7:12:81) to -8°C and dissolve 6g of cellulose, add 16.833g of 2,3-cyclo Oxypropyltrimethylammonium chloride was centrifuged to defoam and remove impurities, and placed at 45°C for 7 days for a homogeneous reaction to obtain a quaternized cellulose solution.

[0053] 2) Preparation of quaternized cellulose beads: the quaternized cellulose solution obtained in step 1) is squeezed through a 1.6mm needle syringe, and dripped to a mass fraction of 10% hydrochloric acid solution at a position 25 cm from the solidification liquid level solidified in the medium, washed with distilled water to remove impurities, and obtained quaternized cellulose beads.

[0054] It has been determined that the quaternized cellulose beads prepared in this example are 6 mm in size, hav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com