Preparation method and product of hollow polymer nanospheres with mesoporous

A technology of nano-microspheres and polymers, which is applied in the preparation of microspheres and microcapsule preparations. It can solve the problems of destroying the active sites on the surface of microspheres, unfavorable preparation of high molecular polymers, and reducing the application range of microspheres. The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

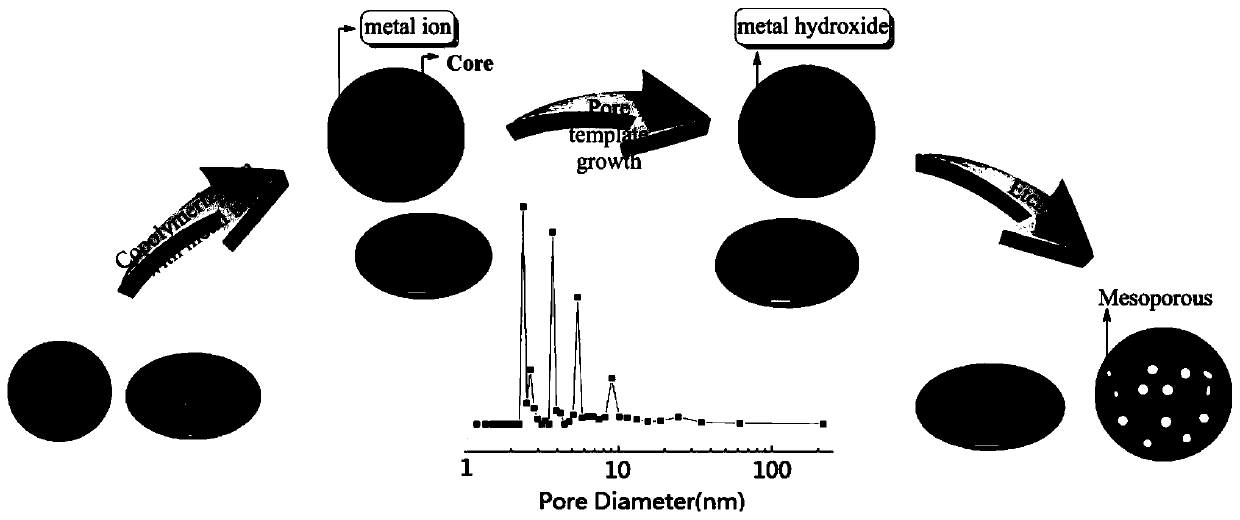

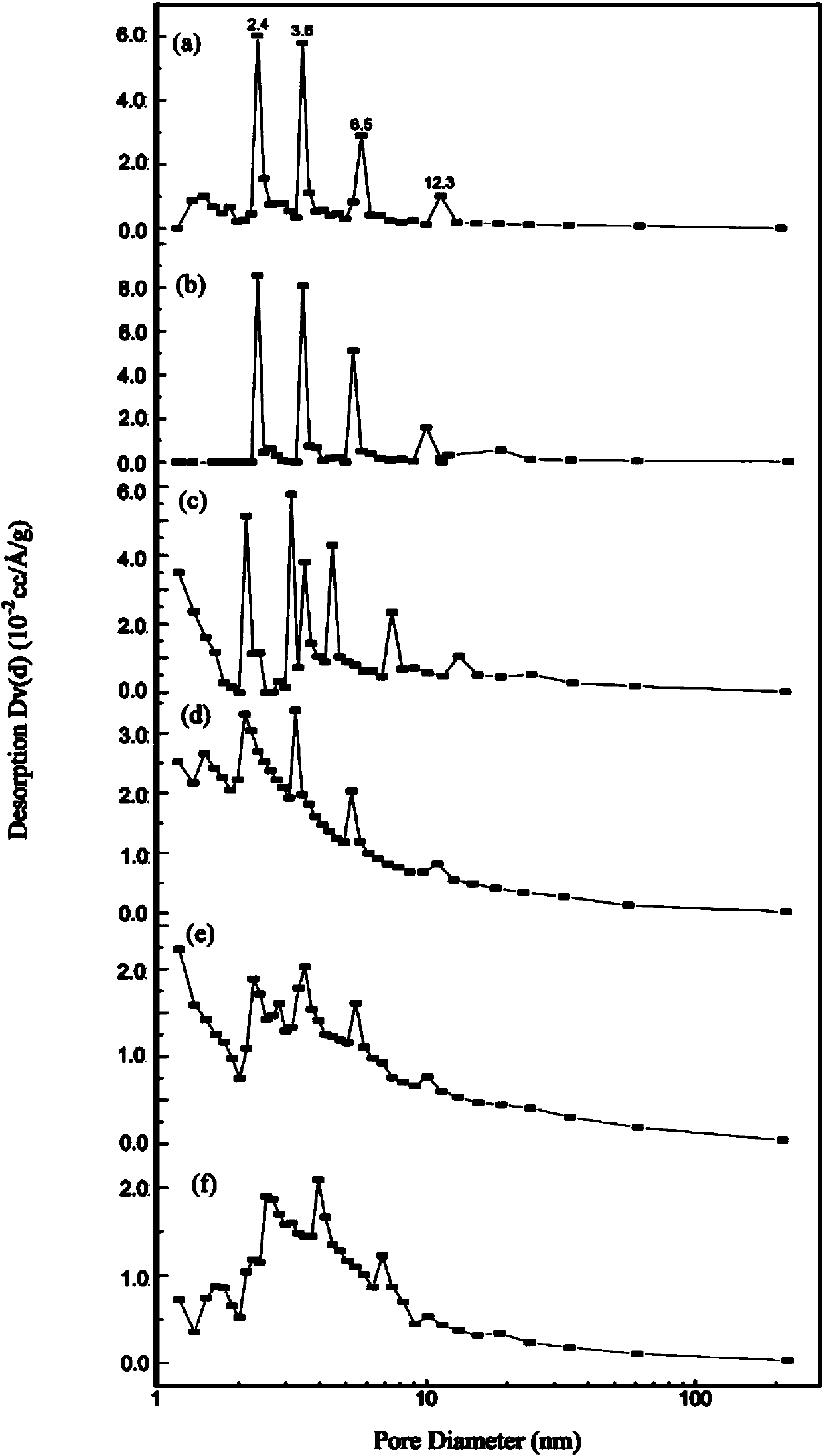

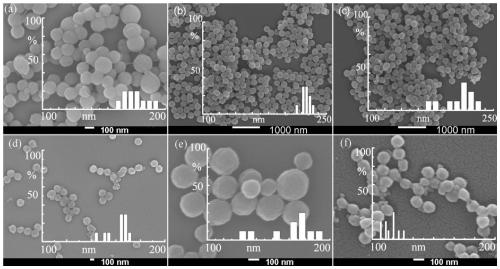

[0031] The preparation method of the hollow polymer nanosphere with mesoporous, its process schematic diagram is as figure 1 As shown, the specific steps are as follows: take polystyrene nanospheres (100mg) and add them to 5mL ethanol / 0.5% polyvinyl alcohol aqueous solution (v / v=1 / 10), stir to obtain polystyrene nanosphere suspension, The suspension was added to N with a syringe 2 In a 200 mL double-neck round bottom flask protected and filled with acrylamide (142 mg, 2.0 mmol), stir evenly, add 10 mL of polyvinyl alcohol aqueous solution with a mass fraction of 0.5%, and stir evenly. St was added sequentially with a syringe (to a final concentration of 64mmol L -1 ), 6mL ethylene glycol dimethacrylate ethanol solution (the final concentration of ethylene glycol dimethacrylate after adding is 20mmol·L -1 ), 4mL KPS aqueous solution (the final concentration of KPS after adding is 3·2mmol·L -1 ) and Zn(OAC) 2 2H 2 O aqueous solution (after adding Zn(OAC) 2 2H 2 The final ...

Embodiment 2-6

[0035] Implementation method and synthesis condition are all identical with embodiment 1, difference is to weigh Zn (OAC) respectively 2 2H 2 O, control the final concentration to 0.08mmol L -1 , 0.16mmol·L -1 , 0.32mmol·L -1 , 0.64mmol·L -1 , 1.28mmol·L -1 A core-shell structure wrapped with different zinc ion concentrations was obtained.

Embodiment 7-9

[0037] Implementation method and synthesis condition are all identical with embodiment 1, difference is to weigh Zn (OAC) respectively 2 2H 2 O, Mn(OAC) 2 4H 2 O and Co(OAC) 2 4H 2 O, so that the final concentration is 0.04mmol L -1 , to obtain core-shell structures wrapping different metal ions, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com