Resin composition

A technology of resin composition and compound, applied in electrical components, circuits, organic chemistry, etc., can solve problems such as deterioration of organic EL components, and achieve excellent coating properties and excellent solubility in acetone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

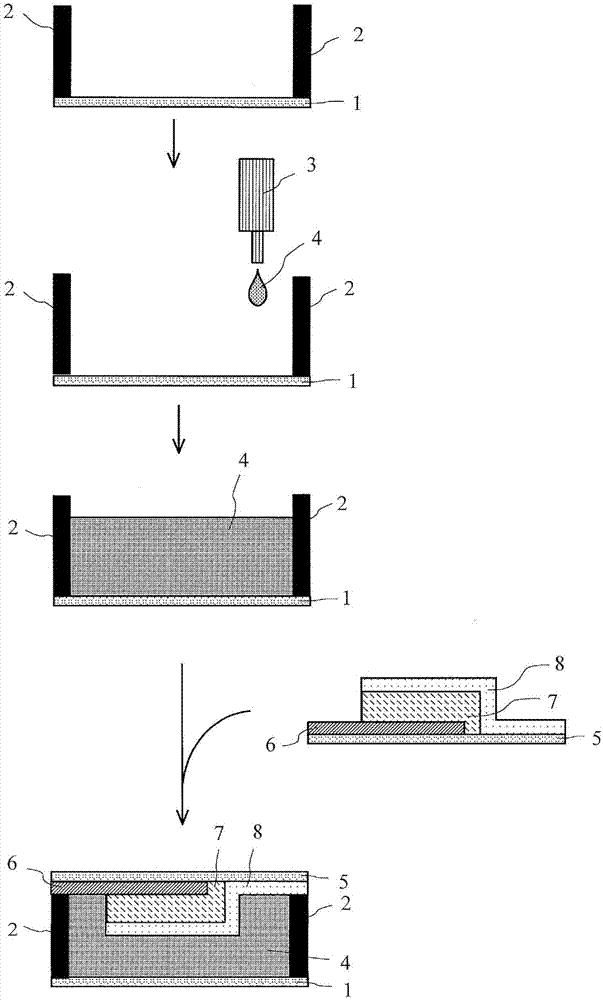

Method used

Image

Examples

manufacture example 1

[0203] Sodium hydride (comprising 55% by weight of mineral oil) (15.4 g, 352.9 mmol) and DMSO (510.6 g) were added to a 2 L four-necked flask equipped with a condenser, a stirrer and a thermometer, and after cooling to 0° C., A solution obtained by dissolving o-phenylphenol (50.6 g, 297.3 mmol) in DMSO (191.0 g) was added dropwise thereto. Thereafter, it was placed in a 60° C. oil bath, and a solution obtained by dissolving 2-chloroethyl vinyl ether (38.2 g, 358.5 mmol) in DMSO (61.4 g) was added dropwise. After stirring the reaction liquid for 6 hours, after cooling to 0 degreeC, water was slowly dripped and quenched, and it transferred to the separatory funnel. The aqueous layer was extracted with ethyl acetate, and saturated brine was added to the organic layer for washing. Thereafter, the organic layer was separated and dehydrated with anhydrous sodium sulfate, and then the solvent was distilled off to obtain a liquid crude product. This was purified by silica gel column...

Embodiment 1

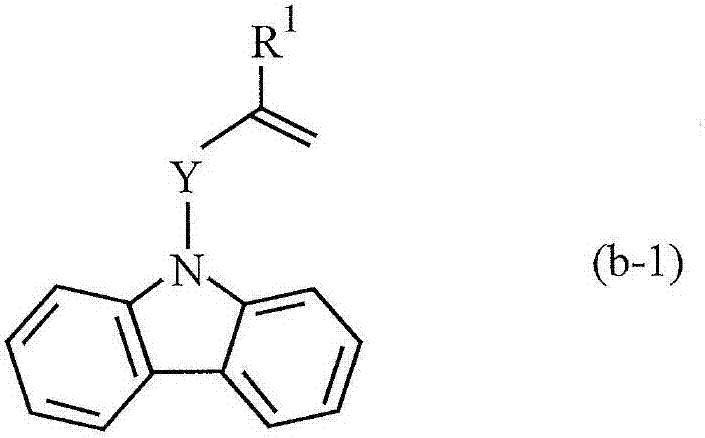

[0208] Put MPV (82 parts by weight), VCZ (17 parts by weight) and photocationic polymerization initiator (1 part by weight) into the rotation and revolution type stirring and defoaming device (model: AR-250, made by Thinky) and stir to obtain the resin Composition (1).

[0209] The obtained resin composition (1) was cast in a mould, and irradiated with ultraviolet light (irradiation dose: 1500mJ / cm2) from a distance of 10cm with a high-pressure mercury lamp of 200W / cm 2 ).

[0210] The viscosity of the obtained resin composition (1) was measured before ultraviolet irradiation, immediately after ultraviolet irradiation, and 30 minutes after ultraviolet irradiation, and the degree of viscosity increase after ultraviolet irradiation was calculated from the following formula.

[0211] Viscosity increase after UV irradiation = Viscosity 30 minutes after UV irradiation / Viscosity immediately after UV irradiation

[0212] Moreover, the resin composition (1) after ultraviolet irrad...

Embodiment 2~7、 comparative example 1~3

[0214] Except having changed to the composition shown in the following table, it carried out similarly to Example 1, and produced the resin composition and hardened|cured material.

[0215]

[0216] By adding 100 mL of acetone to 1 g of the resin compositions obtained in Examples and Comparative Examples, and stirring the acetone solution obtained by using a magnetic stirrer at 25° C. for 1 hour, the transparency of the resin composition was confirmed visually. Solubility was evaluated.

[0217]

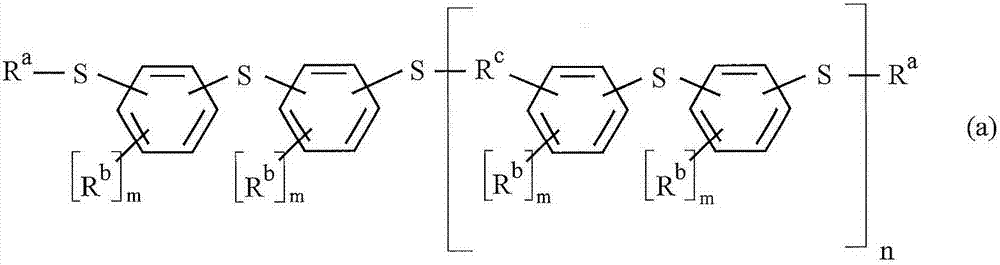

[0218] Preparation of UV delayed curing dam material

[0219] 30 parts by weight of (3,4,3',4'-diepoxy) dicyclohexyl, liquid bisphenol F diglycidyl ether (trade name "YL-983U", manufactured by Mitsubishi Chemical Co., Ltd.) 70 Parts by weight, 4-(4-biphenylthio)phenyl-4-biphenylphenylsulfonium tetrakis(pentafluorophenyl)borate 2 parts by weight, 1,3,4,6-tetraglycidyl 2.5 parts by weight of glycoluril (trade name "TG-G", manufactured by Shikoku Chemical Industry Co., Ltd.), 52 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com