Multi-level recycling system and method for acid-making wastewater of smelting flue gas

A technology for smelting flue gas and recycling it, applied in the chemical industry, can solve the problems of increased lead content, deposition of acid sludge in purification towers, low recycling rate, etc. small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

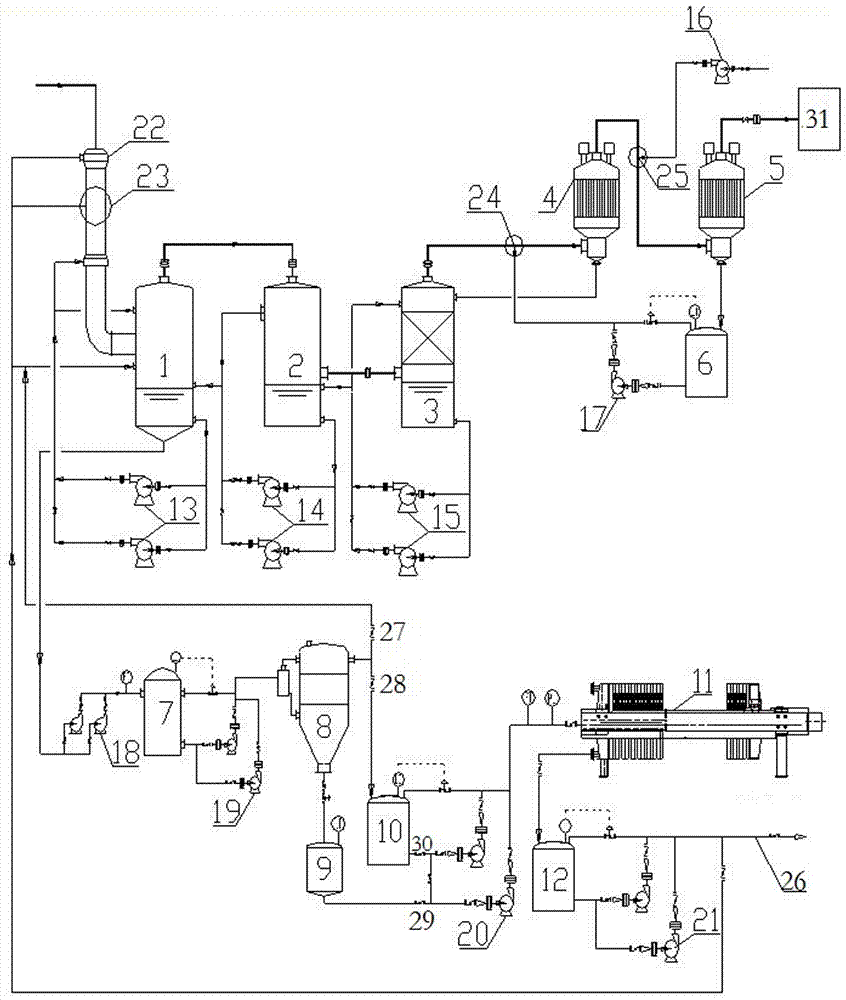

[0022] Such as figure 1 As shown, a multi-level recycling system for waste water from smelting flue gas acid production, including a turbulent tower 1, a washing tower 2, a cooling tower 3, a first-stage electric demister 4 and a second-stage electric demister connected sequentially through the flue 5, wherein, the reverse nozzle of the turbulent tower 1 is provided with a reverse nozzle humidifying nozzle 23, and the circulation tank at the bottom of the turbulent tower 1 is connected with the turbulent tower through two sets of turbulent tower circulation pumps 13 (one on and one on standby) respectively. The spraying device in the flushing tower 1 and the power wave nozzle of the reverse nozzle are connected, and the settlement tank at the bottom of the flushing tower 1 is connected to the acid water buffer tank 7 through two sets of mud pumps 18 (one on and one on standby), and the acid water buffer tank 7 passes through Two sets of acid water buffer pumps 19 (one on and o...

Embodiment 2

[0025] The multi-level recycling system of smelting flue gas acid production wastewater in this example is the same as that in Example 1, and it is applied to smelting flue gas index fluctuations (flue gas HF concentration: 1.96mg / Nm 3 -38.92mg / Nm 3 , with an average concentration of 27.72mg / Nm 3 , dust content in flue gas: 860mg / Nm 3 , Flue gas volume: 171130Nm 3 / h-205884Nm 3 / h, the average gas volume is 188507Nm 3 / h) in abnormal production, the specific steps are the same as Example 1. The acid waste water index in the acid water buffer tank 7 is the highest (acidity: 214.35g / L, fluorine content: 3672.2mg / L, solid content: 34.57 g / L, discharge: 60m 3 / h), filter pressure device 11 clear liquid index (acidity: 221.47g / L, fluorine content: 3519.72mg / L, solid content: 0.036g / L), the discharge can be reduced to 12 m 3 / h. During the abnormal production process, the fluorine content of the flue gas at the outlet of the second-stage electrostatic demister 5 can be contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com