Process for the production of ethylene, propylene and aromatics from oxygenate feedstocks

A compound and ethylene production technology, which is applied in the production of hydrocarbons from oxygen-containing organic compounds, biological raw materials, ethylene production, etc., can solve the problems of low yields of ethylene and propylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

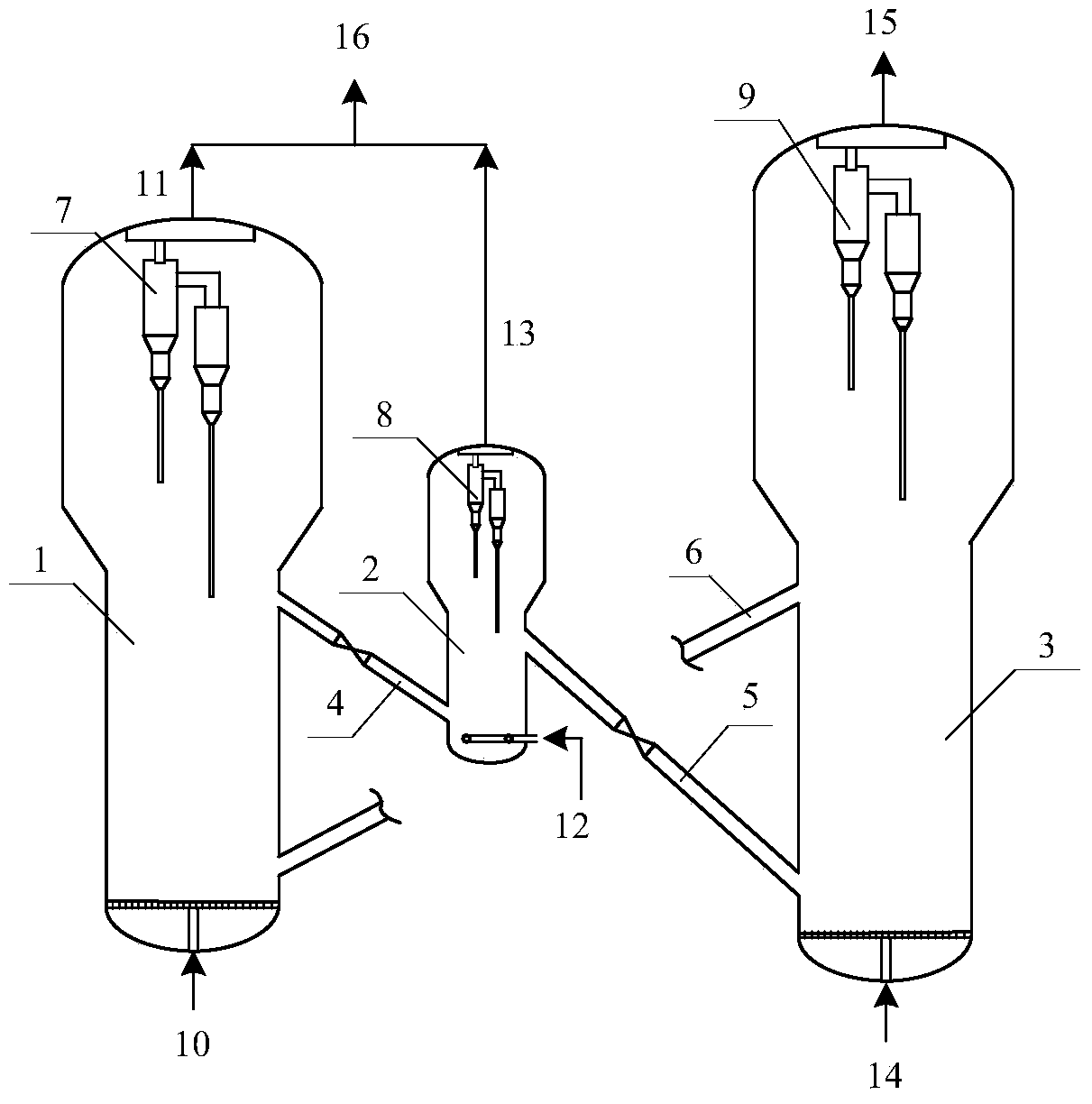

[0034] use as figure 1 The circulating fluidized bed reactor shown. The raw material 10 is methanol, the raw material 12 is ethanol, and the feed mass ratio of the raw material 10 and the raw material 12 is 8:2. The reaction temperature of aromatization reactor 1 is 440°C, the catalyst bed density in the reactor is 450 kg / m3, and the mass space velocity of methanol is 0.1 hour -1 , the reaction pressure is 0 MPa in terms of gauge pressure; the reaction temperature of olefin reactor 2 is 480°C, the catalyst bed density in the reactor is 450 kg / m3, and the mass space velocity of methanol is 0.5 hours -1 , the reaction pressure is 0 MPa in terms of gauge pressure; the temperature of regenerator 3 is 550 ° C, and the regeneration pressure is 0 MPa in gauge pressure; the carbon on the semi-spent catalyst is 3% in terms of the mass percentage of the catalyst . The Ag-ZSM-5 catalyst is adopted, the content of Ag element is 1.3%, the mass ratio of ZSM-5 molecular sieve to matrix is...

Embodiment 2

[0036] use as figure 1 The circulating fluidized bed reactor shown. The raw material 10 is methanol, the raw material 12 is dimethyl ether, and the feed mass ratio of the raw material 10 and the raw material 12 is 6:4. The reaction temperature of aromatization reactor 1 is 520°C, the catalyst bed density in the reactor is 150 kg / m3, and the mass space velocity of methanol is 5 hours -1 , the reaction pressure is 0.4 MPa in terms of gauge pressure; the reaction temperature of olefin reactor 2 is 530°C, the catalyst bed density in the reactor is 80 kg / m3, and the mass space velocity of methanol is 6 hours -1 , the reaction pressure is 0.4 MPa in terms of gauge pressure; the temperature of regenerator 3 is 720 ° C, and the regeneration pressure is 0.4 MPa in gauge pressure; the carbon on the semi-spent catalyst is calculated as a mass percentage of the catalyst, and the content is 0.5% . Using Mn-ZSM-11 catalyst, the mass ratio of ZSM-11 molecular sieve and substrate is 3:7; t...

Embodiment 3

[0038] use as figure 1 The circulating fluidized bed reactor shown. Both raw materials 10 and 12 are dimethyl ether, and the feed mass ratio of raw materials 10 and 12 is 9:1. The reaction temperature of aromatization reactor 1 is 470°C, the catalyst bed density in the reactor is 400 kg / m3, and the mass space velocity of methanol is 2 hours -1 , the reaction pressure is 0.25 MPa in gauge pressure; the reaction temperature of olefin reactor 2 is 520°C, the catalyst bed density in the reactor is 200 kg / m3, and the mass space velocity of methanol is 3 hours -1 , the reaction pressure is 0.25 MPa in gauge pressure; the temperature of regenerator 3 is 650 °C, and the regeneration pressure is 0.25 MPa in gauge pressure; the carbon on the semi-spent catalyst is 1.3% in mass percent of the catalyst . The ZSM-5-β catalyst is adopted, and the mass ratio of ZSM-5 and β molecular sieves to the matrix is 3.5:6.5. The silicon-aluminum molecular ratio of ZSM-5 molecular sieve is 38; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com