Reducing-type polycarboxylate superplasticizer and preparing method thereof

A technology of polycarboxylic acid and water reducer, which is applied in the field of construction admixtures, can solve problems such as high cost, engineering quality problems, and complicated processes, and achieve the effects of reducing surface tension, enhancing shrinkage reduction performance, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

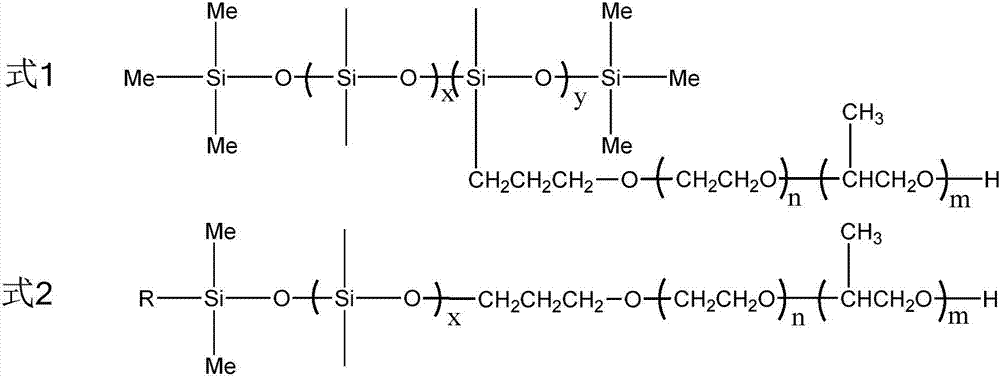

Method used

Image

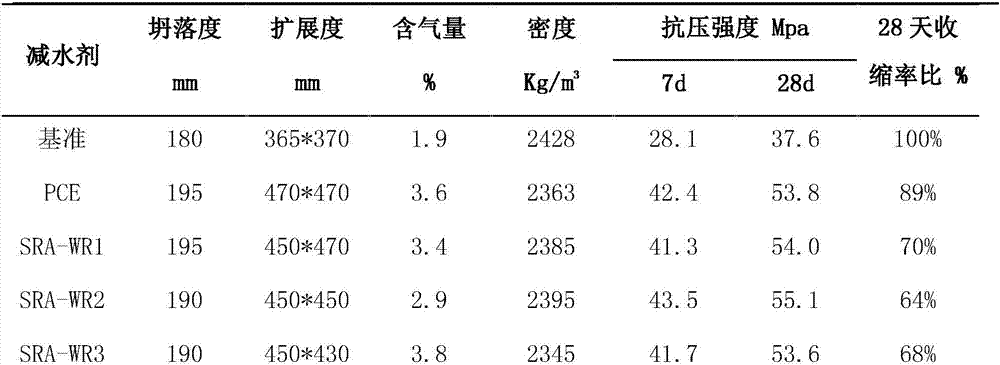

Examples

Embodiment 1

[0021] 1mol of maleic anhydride, 0.8mol of diethylene glycol butyl ether and 0.1mol of PEG-6 polydimethylsiloxane (polyethylene glycol polydimethylsiloxane with a polyoxyethylene addition mole number of 6 ) was added into the reaction flask and stirred at 60 degrees for 4 hours to obtain the mixed maleic acid ester monomer. In a four-necked flask equipped with a stirrer, thermometer, constant temperature heating device and condenser, add 414g of TPEG2400 polyether, 90g of the prepared maleic acid mixed ester and 329g of water, stir and raise the temperature to 40°C until the monomers are completely dissolved Add 4 g of hydrogen peroxide, and start to add dropwise 60 g of initiator aqueous solution (obtained by dissolving 1.25 g of sodium ascorbate, 1.5 g of 3-mercaptopropionic acid in 57.25 g of water) and 60 g of monomer aqueous solution (obtained by dissolving 24.8 g of acrylic acid in 35.2 g of water) , the monomer aqueous solution was added dropwise for 180min, and the ini...

Embodiment 2

[0023] 1.1mol maleic anhydride, 0.8mol dipropylene glycol butyl ether and 0.1mol PEG-8 polydimethylsiloxane (polyethylene glycol polydimethylsiloxane with a polyoxyethylene addition mole number of 8) Add it into the reaction flask and esterify at 60°C for 6 hours to prepare the maleic acid mixed ester monomer. In a four-neck flask equipped with a stirrer, thermometer, constant temperature heating device and condenser, add 408g of TPEG2400 polyether, 82g of prepared maleic acid mixed ester and 320g of water, stir and raise the temperature to 40°C, after the monomers are completely dissolved Add 4g of hydrogen peroxide, and start to drop 60g of initiator aqueous solution (obtained by dissolving 1g of white block in 59g of water) and 60g of monomer aqueous solution (obtained by dissolving 18g of acrylic acid, 1.5g of mercaptoethanol in 40.5g of water), and the monomer aqueous solution drops Add 120min, add the initiator aqueous solution dropwise for 150min, keep warm for 60min af...

Embodiment 3

[0025] 1.1mol of maleic anhydride, 0.9mol of diethylene glycol methyl ether and 0.05mol of PEG-6 / PPG-11 polydimethylsiloxane (polyoxyethylene addition moles are 6 polyoxypropylene addition moles Be 11 polyethylene glycol polypropylene glycol polydimethylsiloxane) join in the reaction flask, add the p-toluenesulfonic acid of 0.5% of total monomer mass, 120 degree of reaction made maleic acid mixed ester monomer in 6 hours . Add 450g VPEG3000 polyether, 75g prepared maleic acid mixed ester and 320g water in four-necked flask, after stirring and dissolving, start to drop 60g initiator aqueous solution (dissolved by 2.5g azobisisobutylamidine hydrochloride in 57.5g obtained in water) and 60g monomer aqueous solution (obtained by dissolving 20g acrylic acid and 1.8g mercaptoethanol in 38.2g water), the monomer aqueous solution was added dropwise for 45min, the initiator aqueous solution was added dropwise for 75min, and after the dropwise addition, the insulation reaction was carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com