Continuous carbonizing treatment process for biomass

A treatment process, biochar technology, applied in the direction of biofuels, educts, petroleum industry, etc., can solve the problems of waste of resources, waste of resources, no further purification of gas, etc., to reduce carbonization time, prevent fires, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

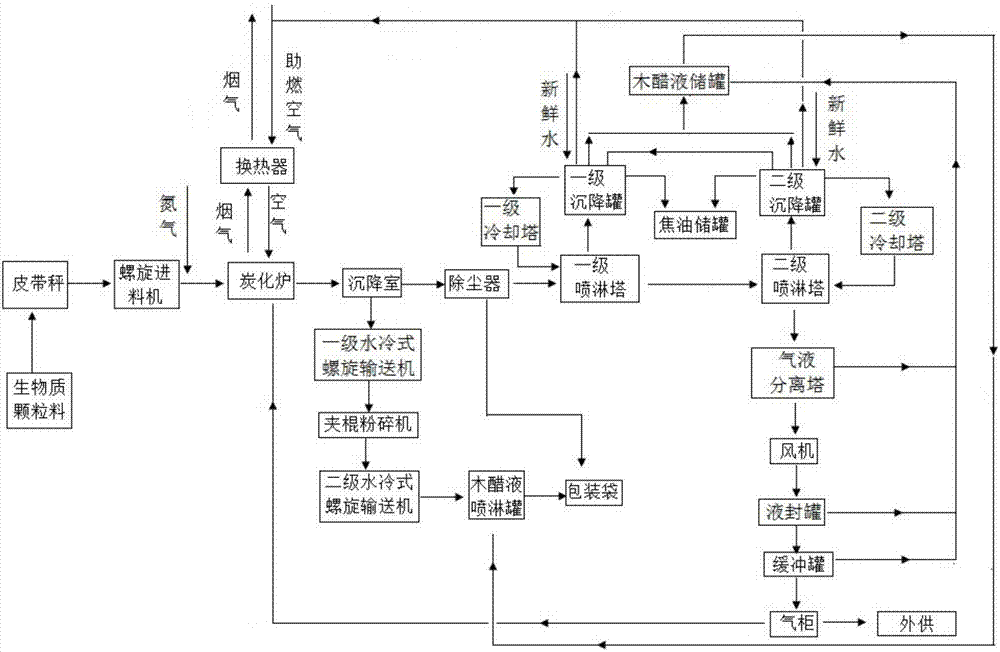

[0037] Such as figure 1 As shown, the present invention provides a kind of biomass continuous carbonization process, comprising the following steps:

[0038] (1) Measure the biomass pellets through a belt scale equipped with an electromagnetic iron remover. The electromagnetic iron remover can separate the damaged parts left in the pellets during the granulation process to prevent damage to the furnace or subsequent clamping sticks from being stuck; the biomass The pellets are transported to the externally heated rotary furnace through the screw feeder, and the pellets are evenly carbonized in the rotating furnace, which is beneficial to reduce the carbonization time and improve the efficiency;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com