Method for preparing hydroxyapatite coating on surface of aluminium oxide

A technology of hydroxyapatite and alumina, applied in coatings, medical science, prostheses, etc., can solve the problems of difficult precise control of process conditions, inability to combine HA coatings, poor long-term implantation stability, etc., and achieve crystallinity Good, good stability, the effect of preventing falling off and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

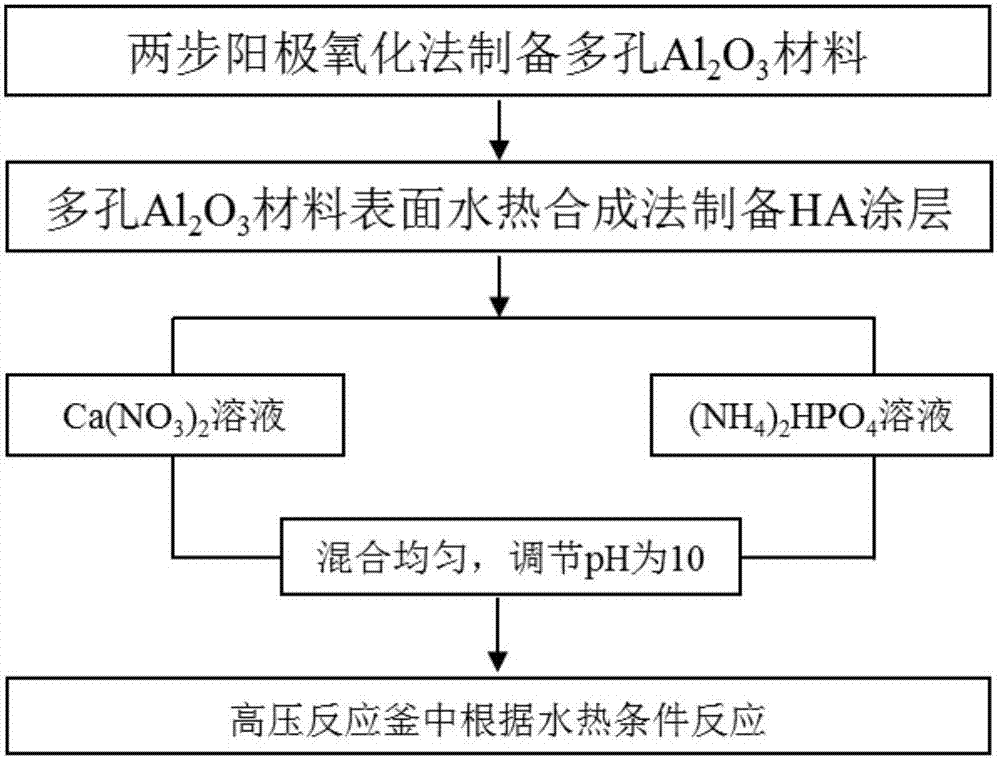

[0040] Embodiment 1, a method for preparing a hydroxyapatite coating on the surface of alumina comprises the following steps:

[0041] Step 1, pre-treatment of the aluminum substrate: first, ultrasonically clean the aluminum substrate with a size of 1mm×1mm×0.5mm in acetone for 20 minutes to remove the grease on its surface, and then put it in 0.5mol / L NaOH solution at 80°C for 5 minutes. Remove the natural oxide film on the surface, wash the aluminum substrate with distilled water after the treatment, and finally, in order to ensure the smooth and bright surface of the aluminum substrate, use H 3 PO 4 (85%), H 2 SO 4 (98%), HNO 3 (68%) mixed acid to chemically polish the aluminum substrate, the volume ratio of the above three solutions is 7:2:1, the polishing temperature is 100°C, and the polishing time is 5min. After polishing, the aluminum substrate is ultrasonically cleaned with distilled water 3 times, the frequency of ultrasonic cleaning is 60-80KHz, the power is 60-...

Embodiment 2

[0044] Embodiment 2, a method for preparing a hydroxyapatite coating on the surface of alumina comprises the following steps:

[0045] Step 1: Pre-treatment of the aluminum substrate: First, ultrasonically clean the aluminum substrate with a size of 1mm×1mm×0.5mm in acetone for 20 minutes to remove the grease on its surface, and then put it in 0.8mol / L NaOH solution for 5 minutes at 80°C. Remove the natural oxide film on the surface, wash the aluminum substrate with distilled water after the treatment, and finally, in order to ensure the smooth and bright surface of the aluminum substrate, use H 3 PO 4 (85%), H 2 SO 4 (98%), HNO 3 (68%) mixed acid to chemically polish the aluminum substrate, the volume ratio of the above three solutions is 7:2:1, the polishing temperature is 100°C, and the polishing time is 5min. After polishing, the aluminum substrate is ultrasonically cleaned with distilled water 3 times, the frequency of ultrasonic cleaning is 60-80KHz, the power is 60-...

Embodiment 3

[0048] Embodiment 3, a method for preparing a hydroxyapatite coating on the surface of alumina comprises the following steps:

[0049] Step 1: Pre-treatment of the aluminum substrate: First, ultrasonically clean the aluminum substrate with a size of 1mm×1mm×0.5mm in acetone for 20 minutes to remove the grease on the surface, and then put it in 1mol / L NaOH solution at 80°C for 5 minutes to remove For the natural oxide film on the surface, wash the aluminum substrate with distilled water after the treatment, and finally, in order to ensure the smooth and bright surface of the aluminum substrate, use H 3 PO 4 (85%), H 2 SO 4 (98%), HNO 3 (68%) mixed acid to chemically polish the aluminum substrate, the volume ratio of the above three solutions is 7:2:1, the polishing temperature is 100°C, and the polishing time is 5min. After polishing, the aluminum substrate is ultrasonically cleaned with distilled water 3 times, the frequency of ultrasonic cleaning is 60-80KHz, the power is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com