A method for enhancing the strength of cemented carbide and metal welding interface

A cemented carbide, metal welding technology, applied in welding equipment, metal processing equipment, nanotechnology for materials and surface science, etc., can solve the problems of cemented carbide block falling off, poor impact resistance, poor interface strength, etc. , to achieve the effect of improving strength, improving hardness and wear resistance, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

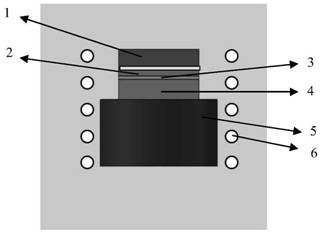

Method used

Image

Examples

Embodiment 1

[0053] a, the configuration of nano-sol, mix aluminum sec-butoxide and distilled water with the ratio of mass molar ratio 0.01:12.4 under magnetic stirring, then add 5ml alcohol, and adjust the pH value with 1mol / l nitric acid at the same time, make the solution The pH value is 3.5±0.5, and the temperature is 60-80°C, and the stirring is continued until the solution becomes clear, and alumina nano-sol is obtained.

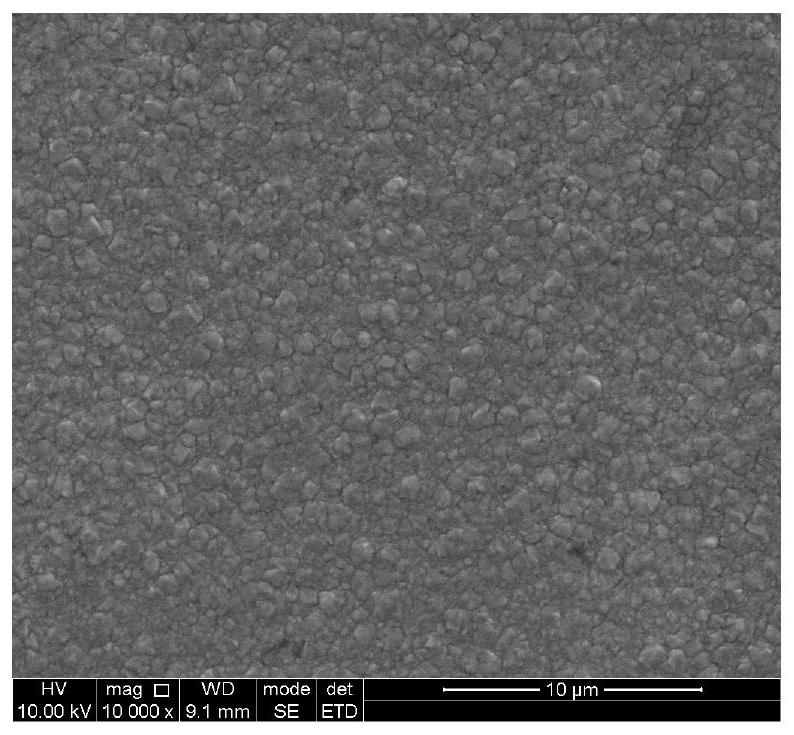

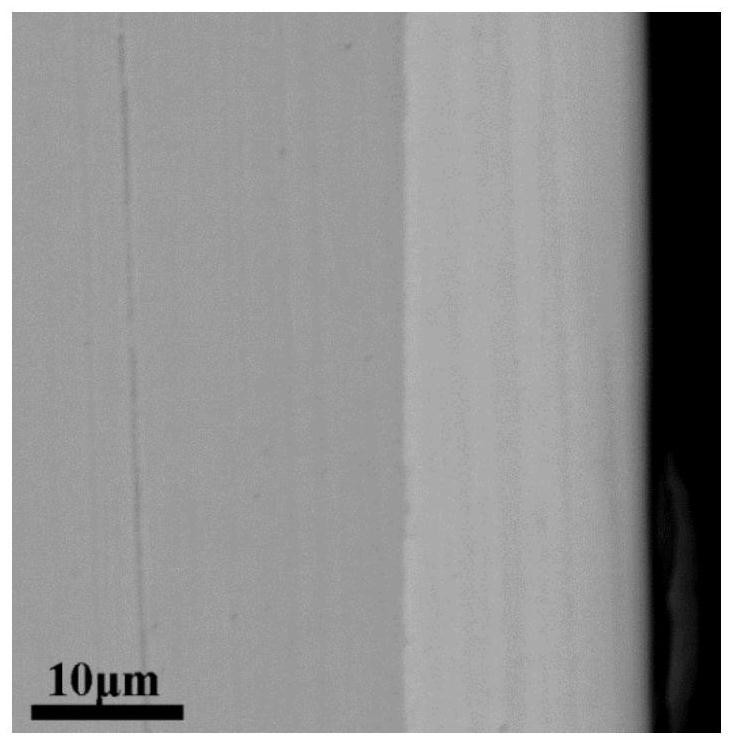

[0054] b. Electroplating scheme, the electroplating method of the composite coating on the steel side firstly grinds the steel with sandpaper and then performs mechanical polishing, and then electrolytically polishes the sample after mechanical polishing. The formula of the electrolyte is absolute ethanol, water, perchloric acid and The volume ratio of 20:3:2 is mixed, the sample is mechanically polished and then electropolished at -25 to -30°C, with a voltage of 1.5V and a polishing time of 20s. And the electropolished steel is electroplated in the plating solutio...

Embodiment 2

[0057] a, the configuration of nano-sol, mix aluminum sec-butoxide and distilled water in the ratio of mass molar ratio 0.01:30 under magnetic stirring, then add 5ml alcohol, adjust the pH value with 1mol / l nitric acid at the same time, make the solution The pH value is 3.5±0.5, and the temperature is 60-80°C, and the stirring is continued until the solution becomes clear, and alumina nano-sol is obtained.

[0058] b. Electroplating scheme, the electroplating method of composite coating on the cemented carbide side firstly grinds the cemented carbide with sandpaper and then performs mechanical polishing, and then performs alkali cleaning and pickling degreasing on the mechanically polished sample. Alkaline degreasing formula: Sodium hydroxide, anhydrous sodium carbonate, sodium silicate, sodium phosphate, its ratio is: 80g / L, anhydrous sodium carbonate: 30g / L, sodium silicate: 15g / L, sodium phosphate: 45g / L, will The sample is immersed in the solution, and degreased at a tempe...

Embodiment 3

[0061] a, the configuration of nano-sol, mix aluminum sec-butoxide and distilled water in the ratio of mass molar ratio 0.01:30 under magnetic stirring, then add 5ml alcohol, adjust the pH value with 1mol / l nitric acid at the same time, make the solution The pH value is 3.5±0.5, and the temperature is 60-80°C, and the stirring is continued until the solution becomes clear, and alumina nano-sol is obtained.

[0062] b. Electroplating scheme, the electroplating method of composite coating on the cemented carbide side firstly grinds the cemented carbide with sandpaper and then performs mechanical polishing, and then performs alkali cleaning and pickling degreasing on the mechanically polished sample. Alkaline degreasing formula: Sodium hydroxide, anhydrous sodium carbonate, sodium silicate, sodium phosphate, its ratio is: 80g / L, anhydrous sodium carbonate: 30g / L, sodium silicate: 15g / L, sodium phosphate: 45g / L, will The sample is immersed in the solution, and degreased at a tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com