Heating furnace tube used for heating gas liquid mixture and/or air-liquid-solid mixture

A gas-liquid mixture and mixture technology, applied in lighting and heating equipment, fixed tubular conduit assemblies, furnaces, etc., can solve the problems of ineffective and effective tubular heating furnaces, tube wall erosion, easy to cause fire, etc., to reduce Consumables costs and labor maintenance costs, production process safety, and the effect of avoiding side wall effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, a kind of tubular heating furnace for heating residual oil, coal powder and hydrogen mixture

[0029] The tubular heating furnace for heating residue oil, pulverized coal and hydrogen mixture in this embodiment includes a spiral furnace tube and a burner 3; the spiral furnace tube is set upright; the burner is arranged on the spiral furnace tube The inner and outer sides of the spiral circumference of the furnace tube;

[0030] The material to be heated in the tube is a mixture of residual oil, coal powder and hydrogen, the Reynolds coefficient is 2000, and the volume percentage of gas is 75vol%.

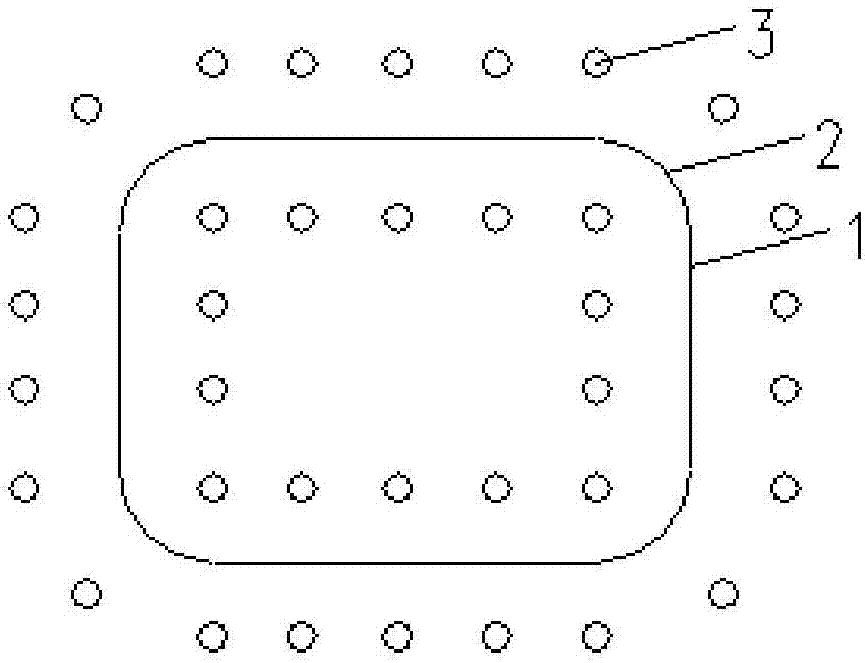

[0031] Such as figure 1 , figure 2 and image 3 As shown, the furnace tube installed in the furnace is a rectangular spiral, and the top view is a rounded rectangle, including a straight pipe section 1 and a curved pipe section 2. The inner diameter of the straight pipe section 1 is 50mm, and the length has two specifications, respectively 2500mm and 2000mm ...

Embodiment 2

[0034] Embodiment 2, a kind of tubular heating furnace for heating residual oil and hydrogen mixture

[0035] The tubular heating furnace for heating residue oil and hydrogen mixture in this embodiment includes a spiral furnace tube and a burner 3; the spiral furnace tube is set upright; the burner is arranged on the spiral furnace tube The inner and outer sides of the helical circle; the material to be heated in the tube is a mixture of residual oil and hydrogen, the Reynolds coefficient is 8500, and the volume percentage of gas is 80vol%.

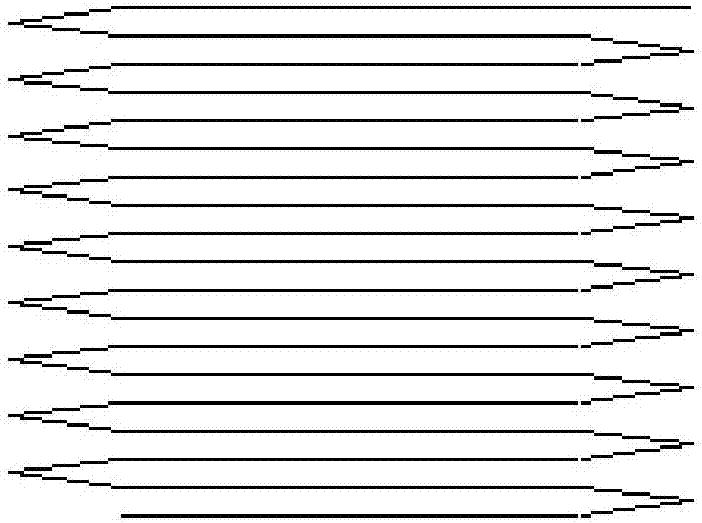

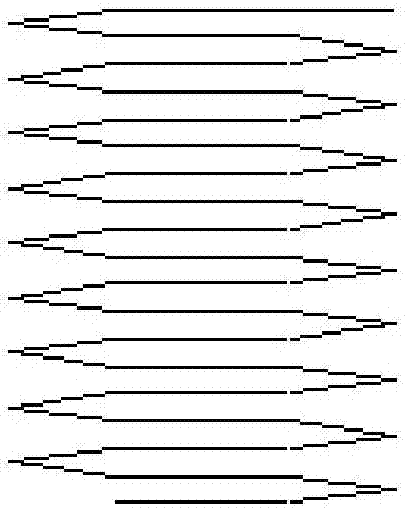

[0036] Such as Figure 4 and Figure 5 As shown, the furnace tube arranged in the furnace is in the shape of a concentric spiral, circular in top view, the inner diameter of the furnace tube is 500 mm, the radius of curvature of the spiral furnace tube is 1500 mm, and the burner 3 is arranged in a linear shape The inner and outer sides of the spiral circle are distributed around the furnace tube on each side. The combustion head of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com