Embedding type sunscreen cream and preparation method thereof

A kind of sunscreen and embedding technology, which is applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., can solve the problems of low light resistance and light stability, achieve good drug release, reduce irritation, reduce Effects of Drug Leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

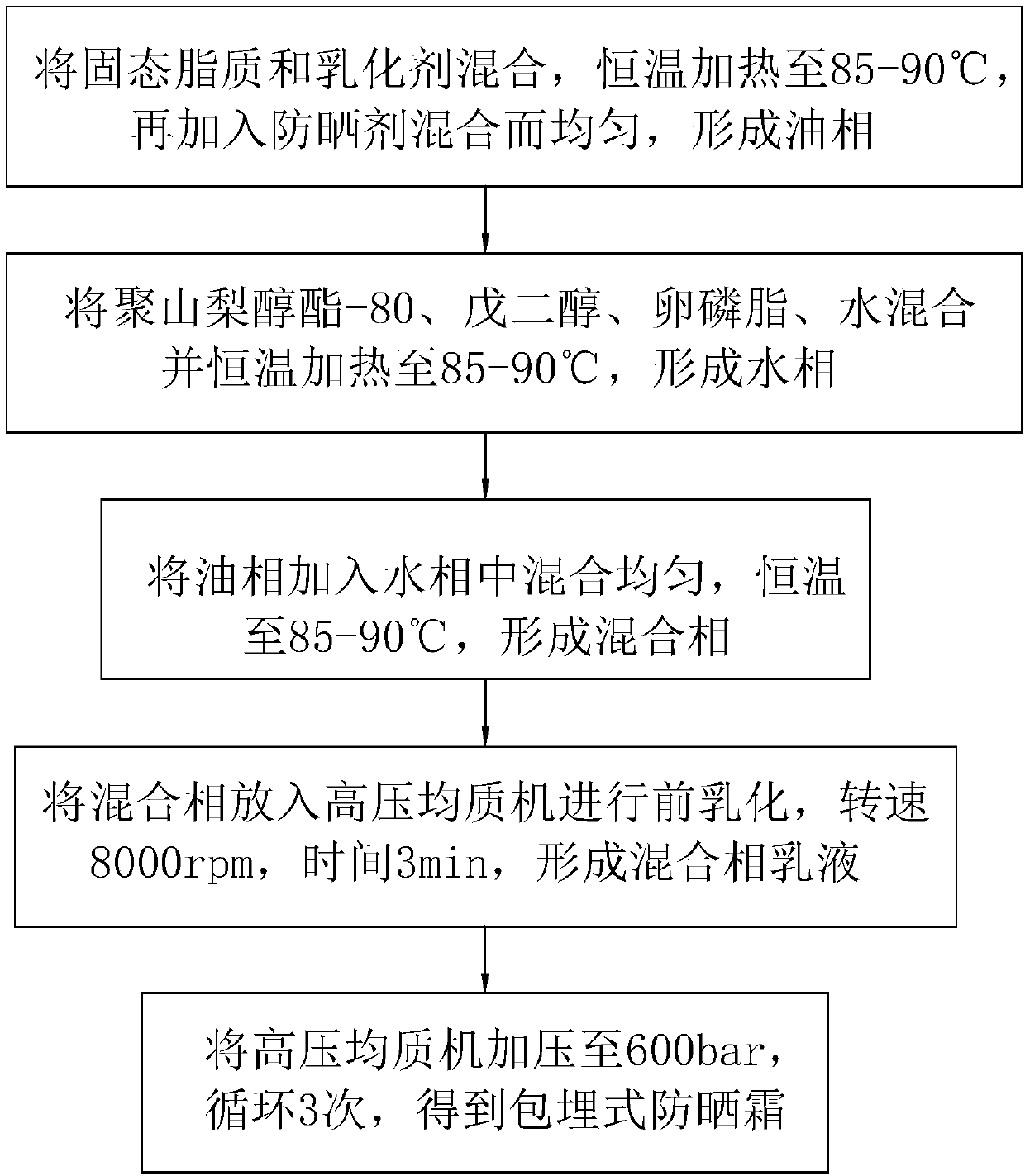

[0044] Embodiment 1: as figure 1 As shown, an embedded sunscreen, each component and its corresponding weight percentage are shown in Table 1, and are prepared through the following steps:

[0045] Step 1: Mix solid lipid and emulsifier, heat at constant temperature to 85-90°C, then add sunscreen and mix evenly to form lipid phase;

[0046] Step 2, mixing polysorbate-80, pentylene glycol, lecithin, and water and heating at a constant temperature to 85-90°C to form a water phase;

[0047] Step 3, adding the lipid phase into the water phase and mixing evenly, keeping the temperature at 85-90°C to form a mixed phase;

[0048] Step 4, put the mixed phase into a high-pressure homogenizer for pre-emulsification at a speed of 8000 rpm for 3 minutes to form a mixed phase emulsion;

[0049] Step 5: pressurize the high-pressure homogenizer to 600 bar, and cycle 3 times to obtain embedded sunscreen.

[0050] Wherein, the sunscreen agent comprises octyl methoxycinnamate, octocrylene, b...

Embodiment 2-10

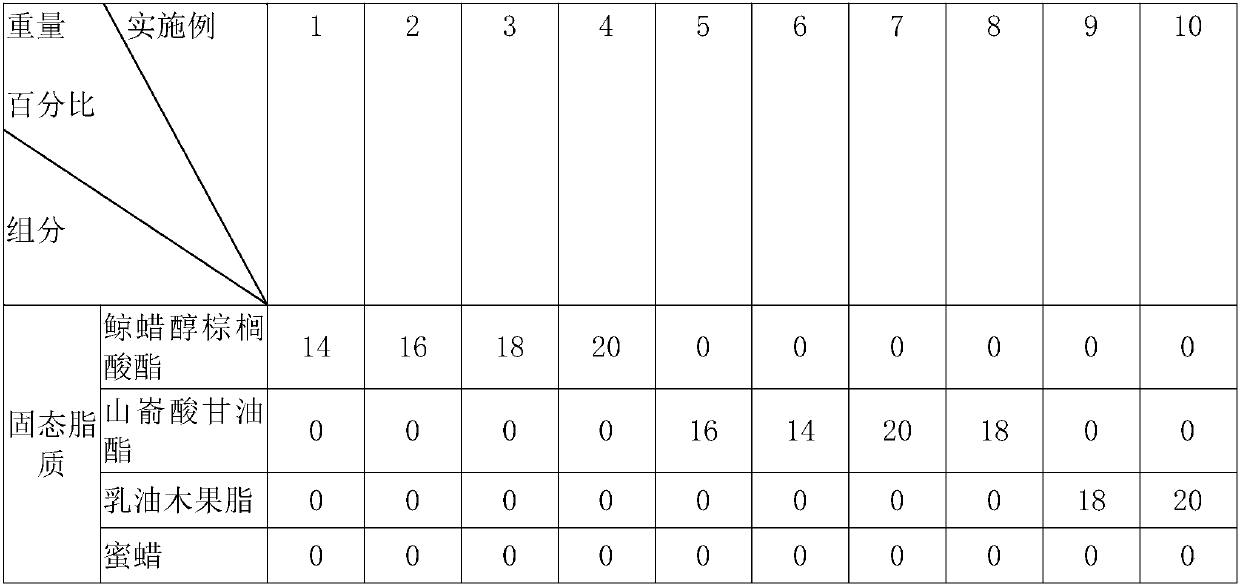

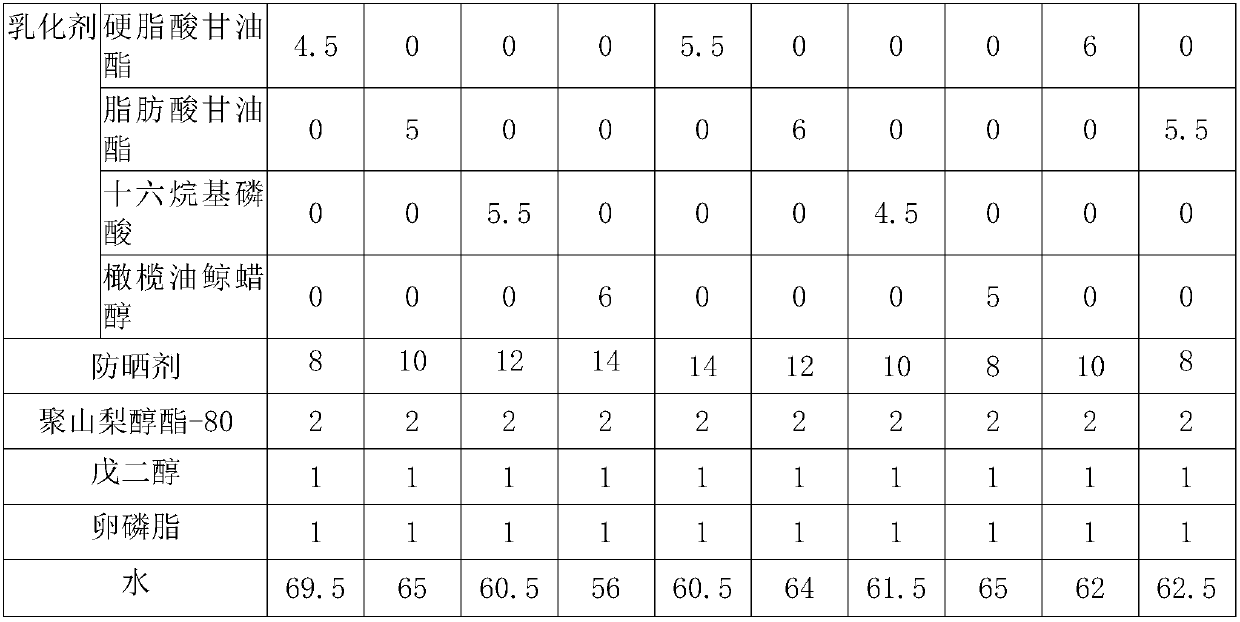

[0051]Example 2-10: An embedded sunscreen, the difference from Example 1 is that each component and its corresponding weight percentage are shown in Table 1.

[0052] Each component and weight percent thereof in table 1 embodiment 1-10

[0053]

[0054]

Embodiment 11-20

[0055] Examples 11-20: An embedded sunscreen, the difference from Example 1 is that each component and its corresponding weight percentage are shown in Table 2.

[0056] Each component and weight percent thereof in table 2 embodiment 11-20

[0057]

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com