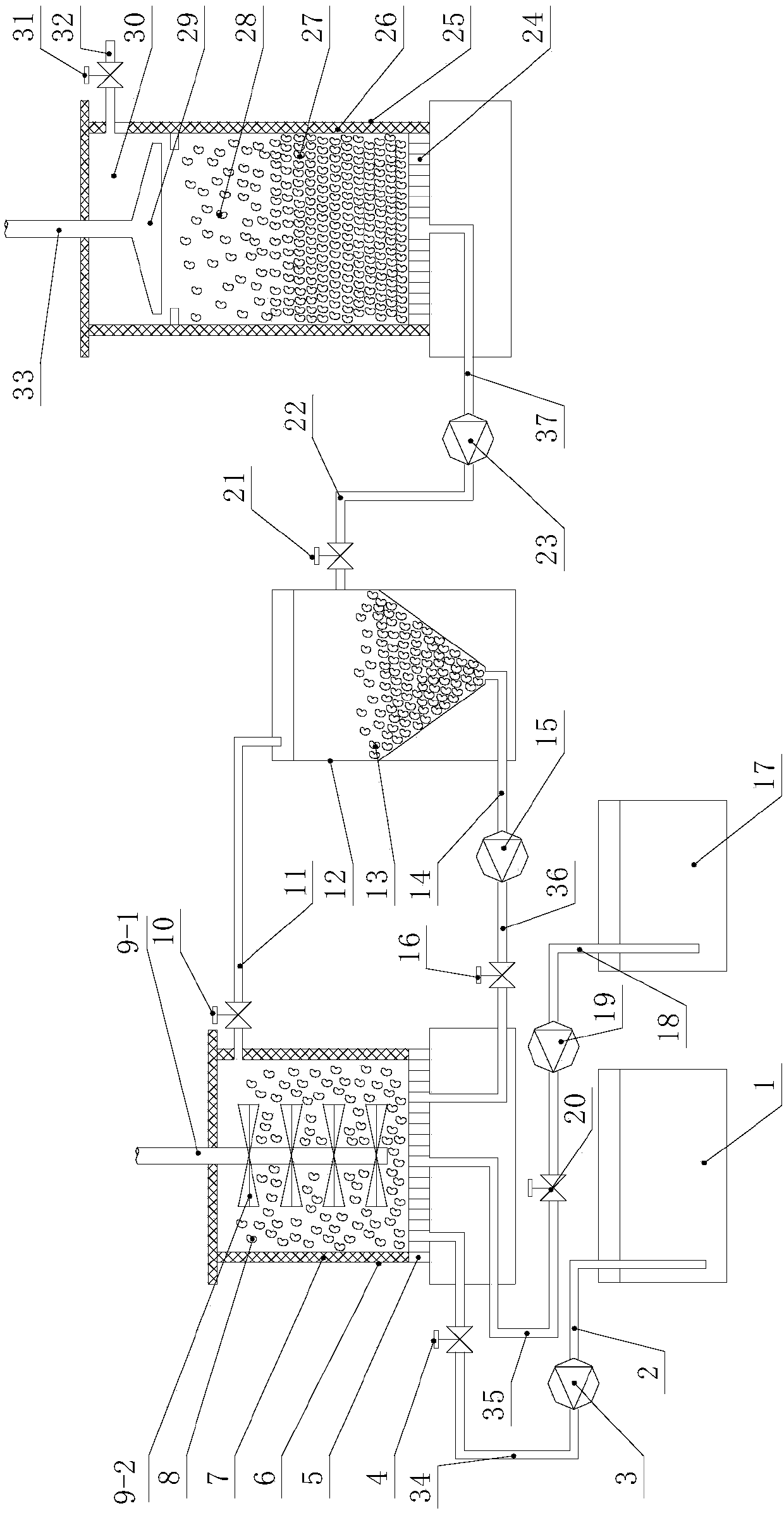

Two-phase anaerobic treatment device and process for establishing direct interspecies electron transfer based on ethanol-type fermentation

An anaerobic treatment device and electron transfer technology, which is applied in the field of environmental protection industry and can solve problems such as increasing the operating cost of anaerobic process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A fully mixed anaerobic digester with an effective volume of 1L was used as the cylinder of the acidification phase, and 400mL of anaerobic sludge was inoculated with a sludge concentration of 8g / L. An upflow anaerobic sludge bed reactor with an effective volume of 2L was used as the cylinder of the methanogenic phase, and 1L of anaerobic sludge was inoculated with a sludge concentration of 20g / L. The organic waste water stored in the water inlet pool is simulated dairy waste water, and the water load is 53KgCOD / m 3 / d, the influent pH is 7.1. Mix concentrated HCI solution (industrial grade, concentration ≥ 95%) with water at a ratio of 1:3 to prepare a 4mol / L dilute HCI solution and store it in an acid adjustment pool. The hydraulic retention time of the acidification phase cylinder is controlled to be 6 hours. The pH in the cylinder is controlled at 4.3, and the temperature is controlled at 27°C. The hydraulic retention time of the methanogenic phase cylinder is co...

Embodiment 2

[0046] A fully mixed anaerobic digester with an effective volume of 1L was used as the cylinder of the acidification phase, and 400mL of anaerobic sludge was inoculated with a sludge concentration of 9g / L. An upflow anaerobic sludge bed reactor with an effective volume of 2L was used as the cylinder of the methanogenic phase, and 0.9L of anaerobic sludge was inoculated with a sludge concentration of 18g / L. The organic waste water stored in the water inlet pool uses actual landfill leachate, and the influent load is 79.2KgCOD / m 3 / d, the influent pH is 8.0. Mix concentrated HCI solution (industrial grade, concentration ≥ 95%) with water at a ratio of 1:3 to prepare a 4mol / L dilute HCI solution and store it in an acid adjustment pool. The hydraulic retention time of the acidification phase cylinder is controlled to be 4 hours. The pH in the cylinder is controlled at 4.5, and the temperature is controlled at 27°C. The hydraulic retention time of the methanogenic phase cylinder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com