Oil-absorbing cement slurry for well cementing and preparation method thereof

A cement slurry and cementing technology, which is applied in the field of oil and gas exploration and development, can solve problems such as singleness and cannot effectively deal with pollution, and achieve huge development and application prospects, good thickening compatibility, and improve the effect of cementing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

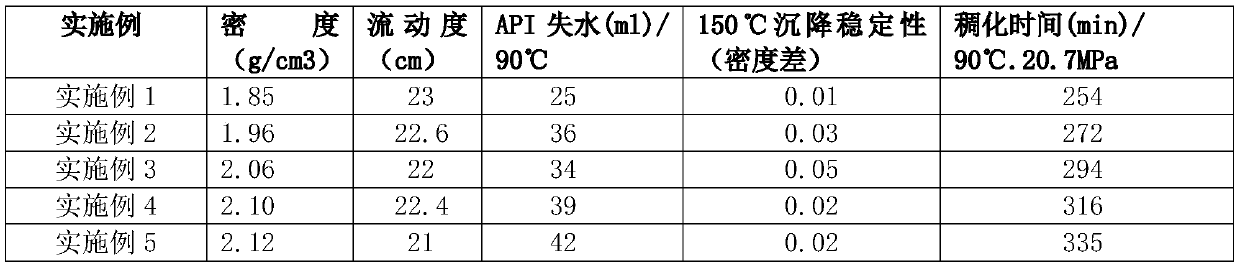

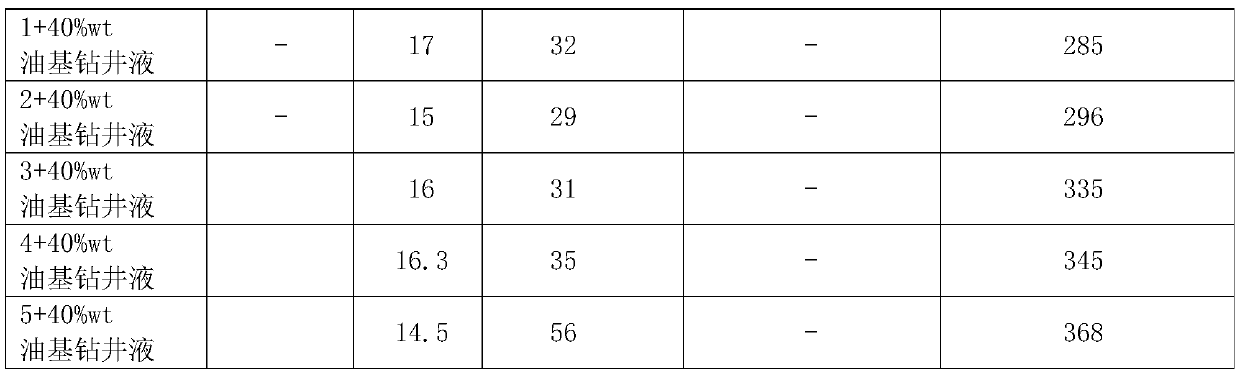

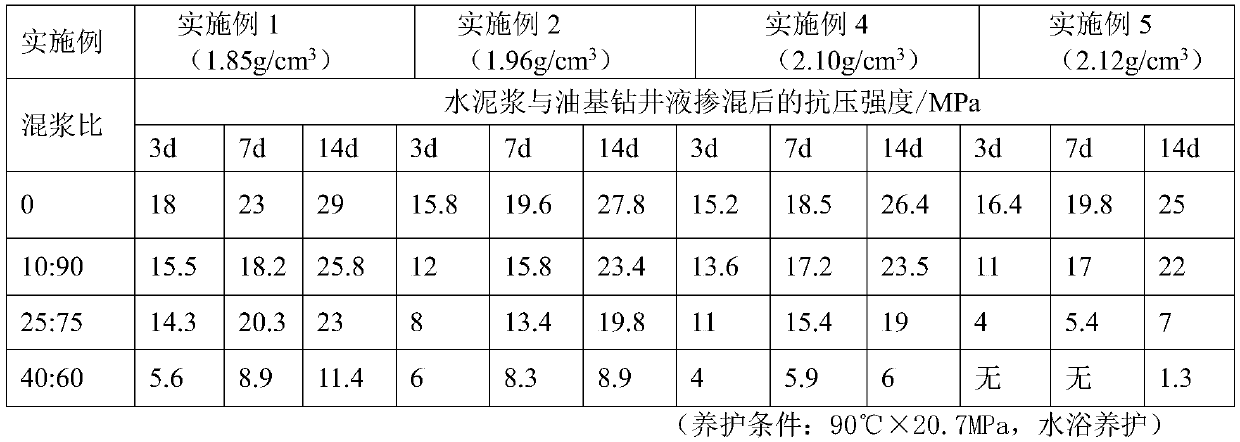

Embodiment 1

[0029] Weigh 4 parts of adsorbent A, 20 parts of indoor self-made adsorbent C, 3 parts of fluid loss reducer, 0.3 part of dispersant, dissolve in 45 parts of fresh water, prepare an aqueous solution, put the aqueous solution under the agitator, and the agitator starts at a low speed (3000±200r / min) rotation, and add 100 parts of cement within 15 seconds, then continue stirring at high speed (12000±500r / min) for 35 seconds, turn on low speed (2000±200r / min), and add 0.2 part of defoamer, and continue to stir for 15 seconds to obtain cementing oil-absorbing cement slurry.

Embodiment 2

[0031] Weigh 3 parts of adsorbent A, 2 parts of adsorbent B, 15 parts of indoor self-made adsorbent C, 4 parts of fluid loss reducer, 0.3 part of retarder, 0.5 part of dispersant, dissolve in 50 parts of fresh water, and prepare an aqueous solution. Put the aqueous solution under the agitator, and the agitator rotates at a low speed (3000±200r / min), and adds 100 parts of cement and 15 parts of weighting agent within 15 seconds, and then continues stirring at a high speed (12000±500r / min) For 35 seconds, turn on at a low speed (2000±200r / min), add 0.2 parts of defoamer, and continue stirring for 15 seconds to obtain cementing oil-absorbing cement slurry.

Embodiment 3

[0033] Weigh 1 part of adsorbent A, 4 parts of adsorbent B, 30 parts of indoor self-made adsorbent C, 5 parts of fluid loss reducer, 0.5 part of retarder, 0.5 part of dispersant, dissolve in 53 parts of fresh water, and prepare an aqueous solution. Put the aqueous solution under the agitator, and the agitator rotates at a low speed (3000±200r / min), and adds 100 parts of cement and 20 parts of weighting agent within 15 seconds, and then continues stirring at a high speed (12000±500r / min) For 35 seconds, turn on at a low speed (2000±200r / min), add 0.2 parts of defoamer, and continue stirring for 15 seconds to obtain cementing oil-absorbing cement slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com