Preparation method and application of customizable photothermal conversion material

A light-to-heat conversion material and light-to-heat conversion technology, applied in phototherapy, additive processing, etc., can solve the problems of strong intermolecular force, high temperature, etc., and achieve the effect of simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

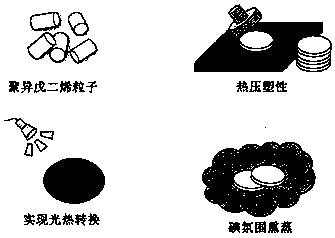

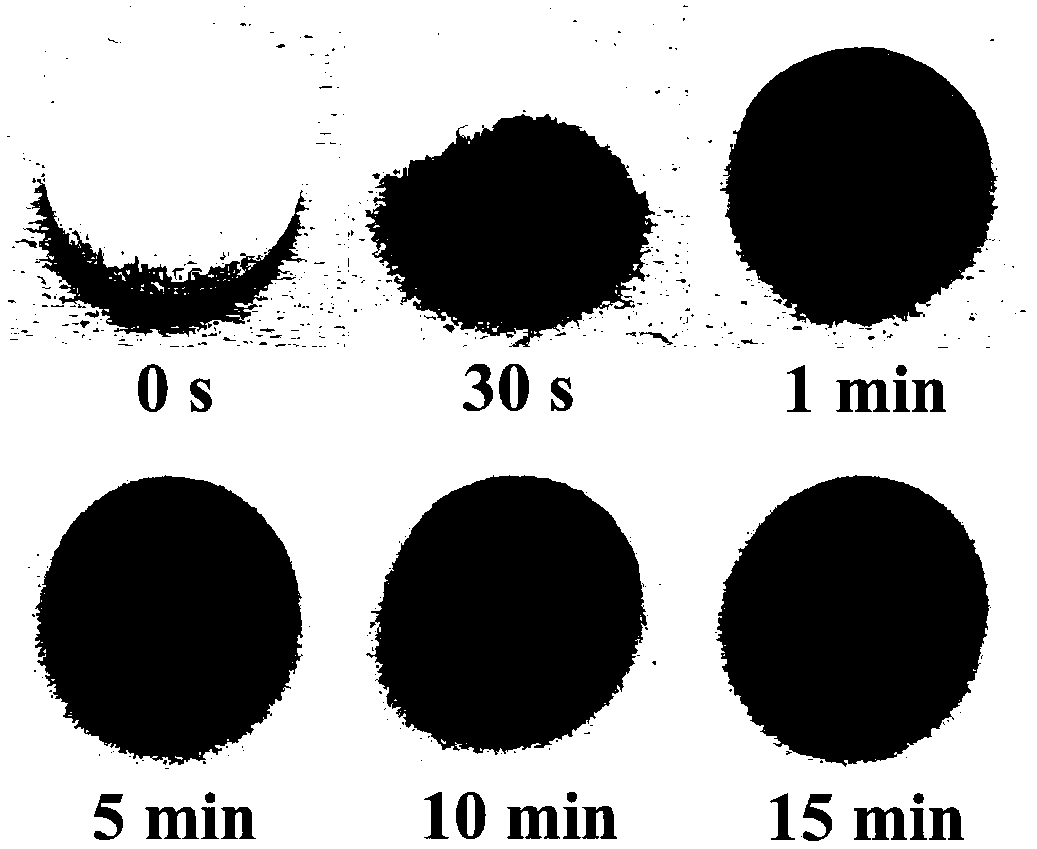

[0029] Example 1. Preparation of sheet-like light-to-heat conversion black material and its response to light

[0030] (1) Preparation of sheet-like light-to-heat conversion black material

[0031] Polyisoprene particles (0-100) with a certain Mooney viscosity are melted and hot-pressed into thin sheets at a certain temperature (60-300°C) and a certain pressure (0-100N), and cooled to room temperature (cooling speed is 10-200℃ / s);

[0032] Place the flakes in an airtight container (container size 1-10°C) saturated iodine vapor (temperature 0-200°C) 10 cm 3 ) at different times (placement time ranges from 1 second to 3 months) to complete the transition from non-conjugated polymers to light-to-heat conversion materials;

[0033] Treat the freshly prepared TPI flakes with ethanol (concentration can be 50% to 99.99%) until the ethanol is colorless, and dry in an oven (vacuum degree can be 0-10%) 5 pa, the oven temperature can be 0-200°C).

[0034] The schematic diagram of th...

Embodiment 2

[0040] Example 2. Preparation and application of three-dimensional printing customizable light-to-heat conversion materials

[0041] (1) Preparation of printable trans 1,4-polyisoprene blending splines

[0042] Trans 1,4-polyisoprene strips were processed using a twin-screw extruder (Haake PolyLab, advance speed can be 1-1000 rpm). The mouth of the machine is equipped with a die to obtain a uniform spline with a diameter of about 0.1-100mm. In addition, polymers that can be blended in the trans 1,4-polyisoprene blending spline include polyethylene, polypropylene, polylactic acid, polyvinylidene fluoride, polyvinyl chloride, polystyrene, acrylonitrile - Butadiene - styrene, polyoxymethylene, polycarbonate, polyamide, acrylic plastic, polysulfone, polyphenylene ether and other thermoplastic polymers.

[0043] (2) Modeling and printing customized physiotherapy products and extended applications

[0044] 2-2 Use a computer and a scanner to build a physiotherapy knee pad model acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com