Styrene-butadiene redispersible emulsion powder and preparation method thereof

A technology of redispersible latex powder and carboxylated styrene-butadiene emulsion, applied in the field of emulsion, can solve the problems of mutual repulsion, thickening, inability to prepare redispersible latex powder by spray drying, etc. Water loss properties, the effect of improving physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

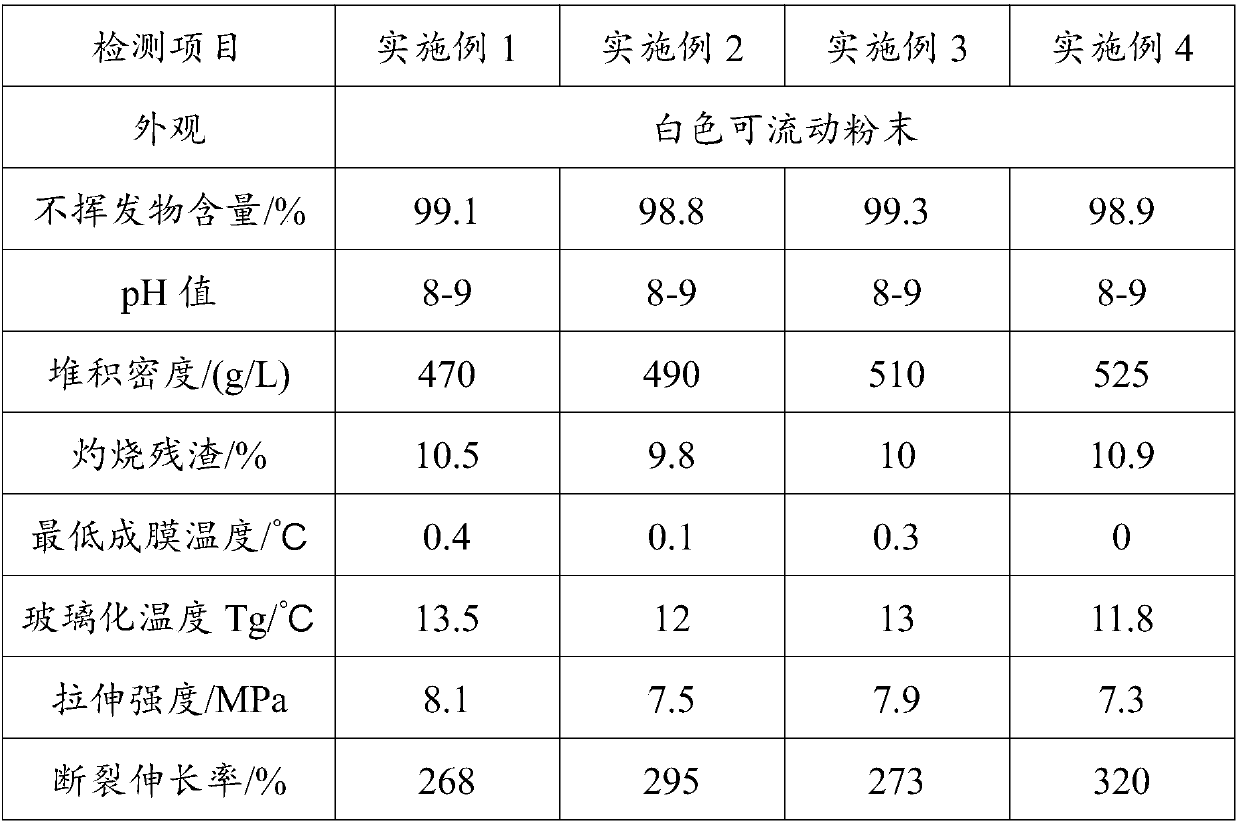

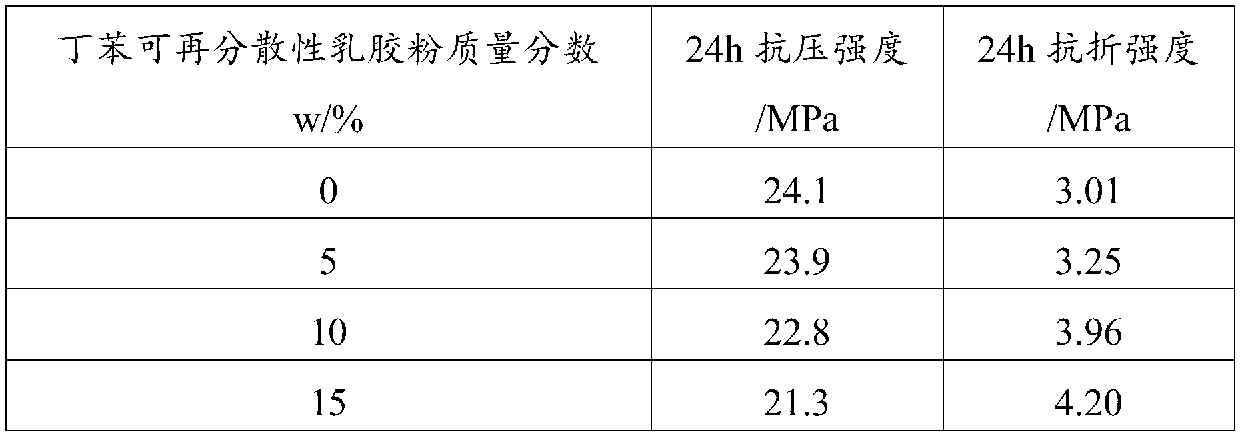

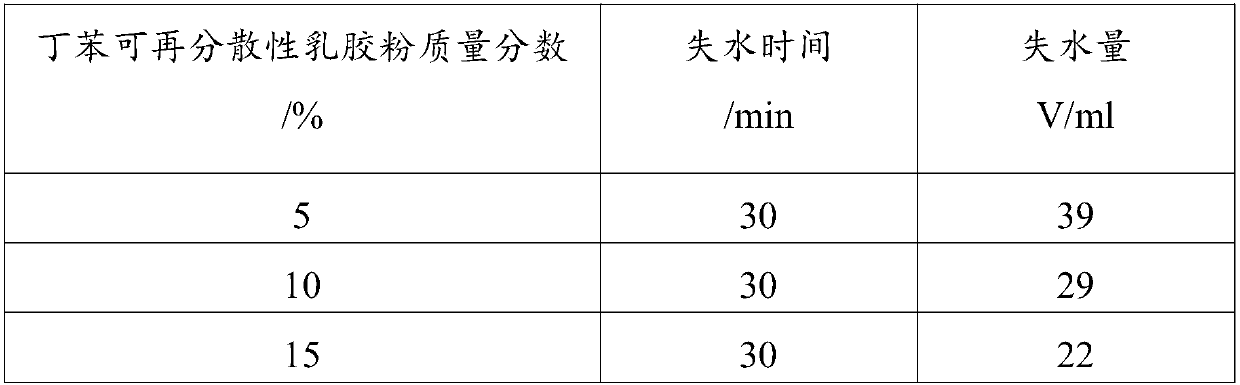

Examples

preparation example Construction

[0032] The present invention also provides a kind of preparation method of described redispersible latex powder, and this method comprises the following steps:

[0033] (1) preparing a mass percentage composition of 20% polyvinylpyrrolidone aqueous solution, a mass percentage composition of 20% polyvinyl alcohol aqueous solution, and a mass percentage composition of 10% pH regulator solution;

[0034] (2) Take the carboxylated styrene-butadiene emulsion in the reactor, and start stirring;

[0035] (3) Then, add the pH regulator solution, surfactant, polyvinylpyrrolidone aqueous solution, carboxylic acid, polyvinyl alcohol aqueous solution, and defoamer to the reaction kettle while stirring to obtain a mixture;

[0036] (4) The mixture in step (3) is spray-dried into powder, and the anti-caking agent is added at the same time to obtain the redispersible latex powder.

[0037] The styrene-butadiene redispersible latex powder of the present invention adopts the adding sequence o...

Embodiment 1

[0042] A kind of styrene-butadiene redispersible latex powder comprises the component of following mass percent: carboxylated styrene-butadiene emulsion 60%, nonylphenol polyoxyethylene ether 1.6%, polyvinylpyrrolidone 1%, citric acid 1.2%, polyvinyl alcohol ( The degree of alcoholysis is 88%, the degree of polymerization is 500) 5%, ammonia water 0.03%, organic silicon defoamer 0.4%, kaolin 6.5%, deionized water 24.27%.

[0043] The preparation method of this styrene-butadiene redispersible latex powder may further comprise the steps:

[0044] (1) Weighing 1% of the polyvinylpyrrolidone and dissolving it in 4% of deionized water is prepared into a 20% polyvinylpyrrolidone aqueous solution; weighing 5% of the polyvinyl alcohol and dissolving it in deionized water 20% of the polyvinyl alcohol solution was prepared as 20% by mass, and the 0.03% ammonia water was weighed and dissolved in 0.27% of deionized water to prepare a 10% ammonia solution by mass;

[0045] (2) Take the carb...

Embodiment 2

[0049] A kind of styrene-butadiene redispersible latex powder comprises the component of following mass percent: carboxylated styrene-butadiene emulsion 71.5%, nonylphenol polyoxyethylene ether 1.2%, polyvinylpyrrolidone 0.48%, citric acid 1%, polyvinyl alcohol ( The degree of alcoholysis is 88%, the degree of polymerization is 500) 3.5%, ammonia 0.02%, fatty acid ester defoamer 0.2%, white carbon black 2.5%, heavy calcium carbonate 3.5%, deionized water 16.1%.

[0050] The preparation method of this styrene-butadiene redispersible latex powder may further comprise the steps:

[0051] (1) Weigh 0.48% of the polyvinylpyrrolidone and dissolve it in 1.92% of deionized water, and prepare it into an aqueous solution of polyvinylpyrrolidone with a mass percentage of 20%; weigh 3.5% of the polyvinyl alcohol and dissolve it in deionized water 14% of the polyvinyl alcohol solution was prepared as a 20% aqueous polyvinyl alcohol solution by mass, and the 0.02% ammonia water was weighed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com