Phase-change microcapsules for inorganic metal oxide coated hydrous salt and preparation method

A technology of phase change microcapsules and inorganic metals, which is applied in the direction of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., can solve redundant problems and achieve the effects of high phase change enthalpy, simple process and large thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

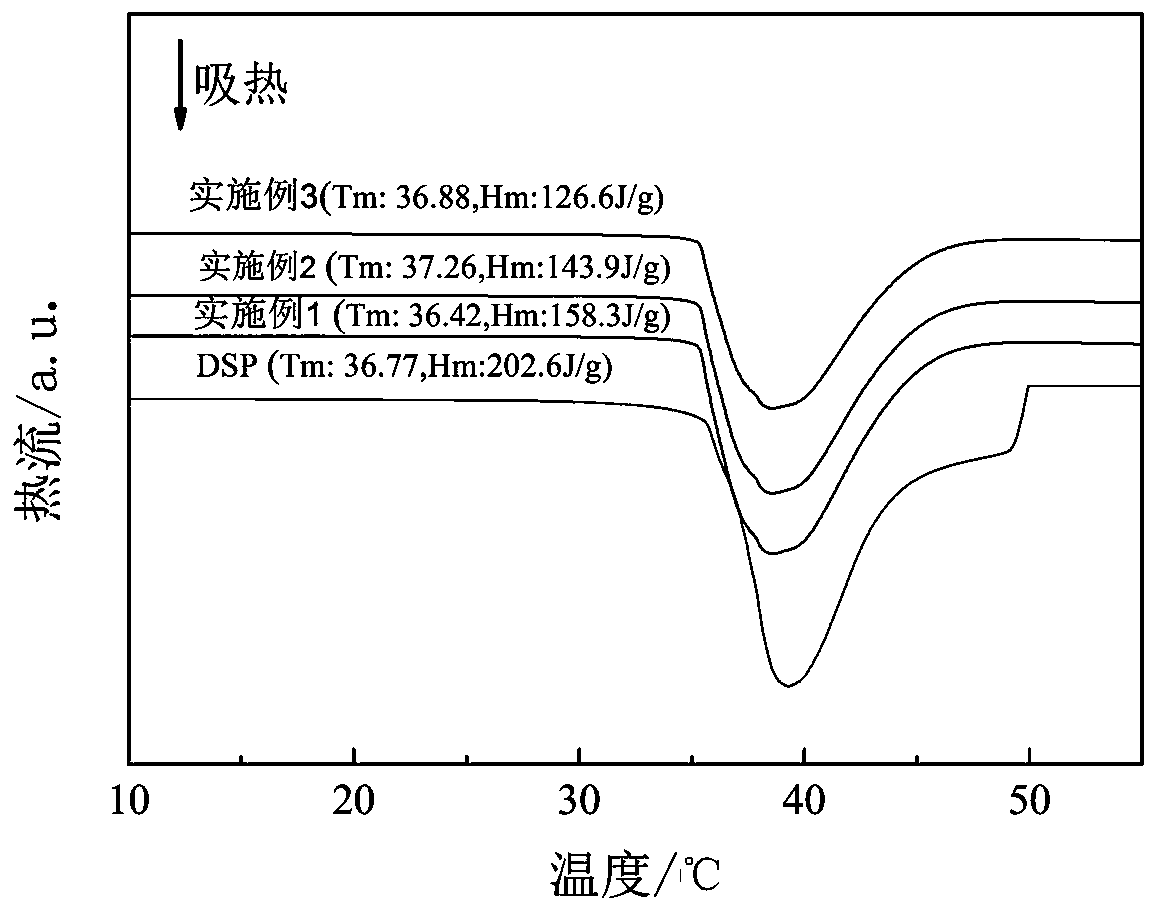

Embodiment 1

[0036] Example 1 (1) At room temperature, put a 250ml three-neck flask with a magnet and a dropping funnel in a water bath with digital magnetic stirring, add 100mL of ethanol (anti-solvent) into the flask, and then drop Tetraethyl orthosilicate (TEOS) 5mL was stirred by magnetic force to obtain a homogeneous solution A; similarly, at room temperature, add 10g of disodium hydrogen phosphate (DSP) powder into a 50mL beaker at room temperature (the mass of DSP added is slightly higher than that at room temperature The mass required for its solubility), then add 30mL deionized water to dissolve, and add 1mL ammonia water dropwise, seal and magnetically stir fully, when the DSP solid in the beaker is no longer dissolved, take the upper layer of colorless transparent clear liquid to obtain alkaline DSP saturation Solution B.

[0037] (2) Adjust the water bath temperature (25°C) and dispersing stirring rate (2000rpm) of the device containing solution A. Under airtight conditions, ac...

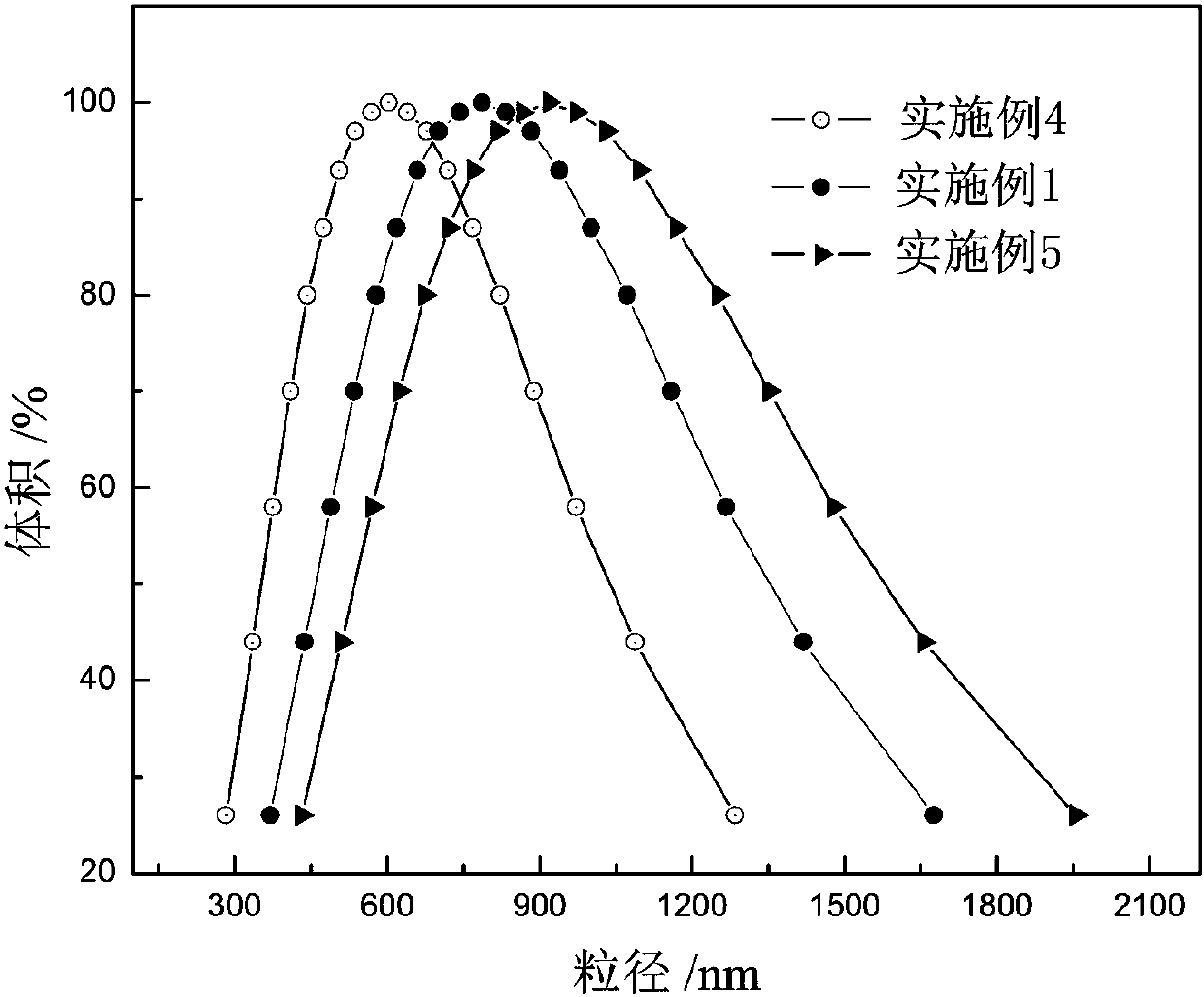

Embodiment 2-8

[0040] Since the experimental process is exactly the same, only the experimental conditions are changed, therefore, Examples 2-8 are listed in tabular form (see Table 1).

[0041] Table 1 Preparation process conditions of metal oxide-coated hydrated salt phase-change microcapsules in Examples 2-8

[0042] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com