Method for comprehensively recycling valuable metals from cyanidation tailings

A technology for cyanidation of tailings and valuable metals, applied in the direction of improving process efficiency, etc., can solve the problems of low grade of coarse gold powder, low gold and silver recovery rate, and high production cost, achieve high metal recovery rate and shorten the process flow. , the effect of improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

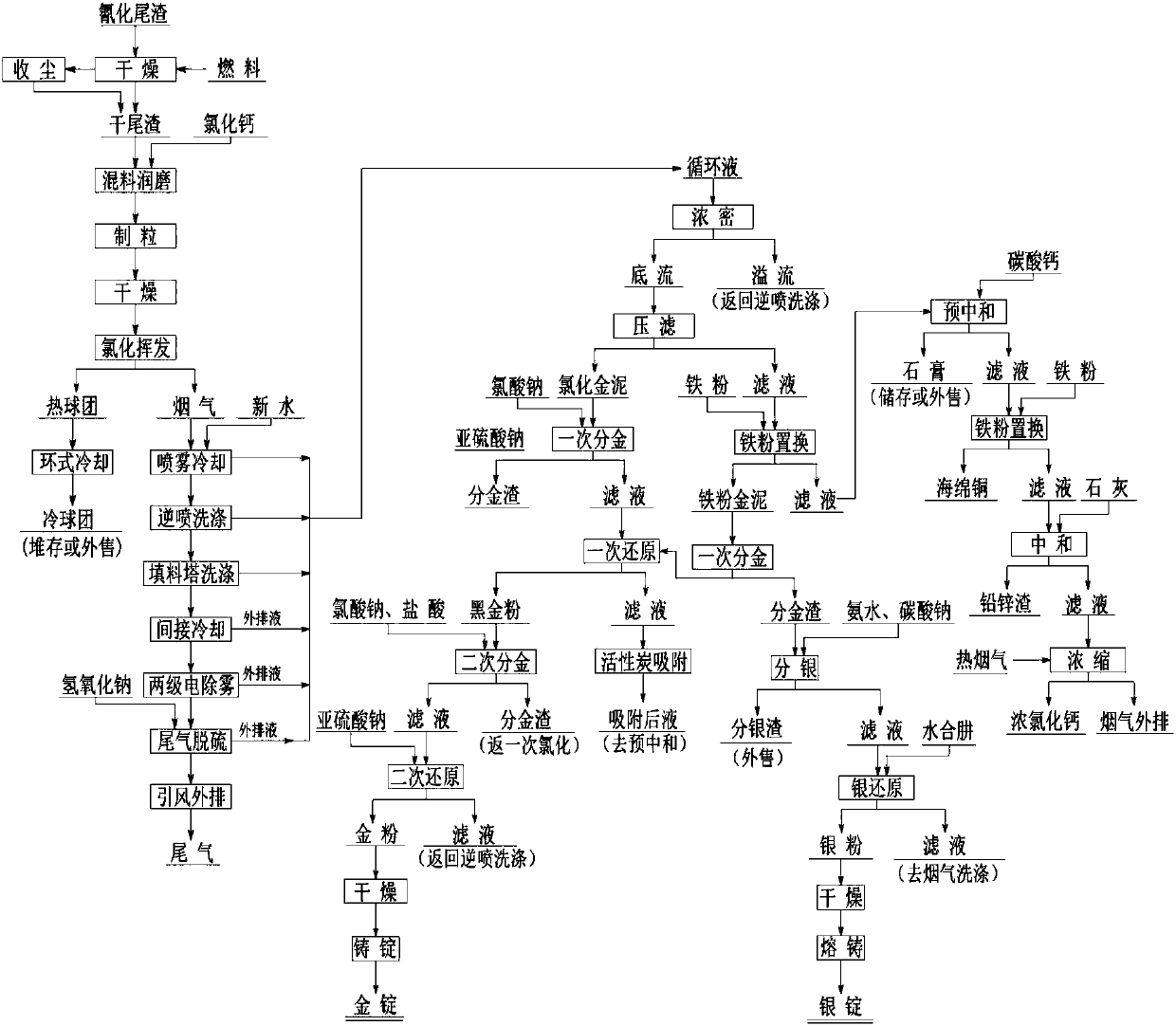

[0057] like figure 1 As shown, a method for comprehensive recovery of valuable metals from cyanide tailings is used to treat a certain cyanide tailings. The main components of the cyanide tailings are: Au 6.43g / t, Ag 12.69g / t t, Fe 28.2wt%, S 1.0wt%, Cu0.064wt%, Pb 0.102wt%, Zn 0.153wt%, SiO 2 37.71wt%, As 0.55wt%, and the particle size of the cyanide tailings is -200 mesh, which accounts for 90%; the specific processing steps of the method for comprehensive recovery of valuable metals from the cyanide tailings are as follows figure 1 And described in above-mentioned step A to step I, thereby can reclaim multiple valuable metals such as gold, silver, copper, zinc, lead, and gold volatilization rate is 93.5%, silver volatilization rate is 68%, copper volatilization rate is 83.1%, The lead volatilization rate was 92.4%, the zinc volatilization rate was 78.6%, the gold recovery rate was 92.1%, the silver recovery rate was 66.6%, the copper recovery rate was 82.0%, the lead reco...

Embodiment 2

[0059] like figure 1 As shown, a method for comprehensive recovery of valuable metals from cyanide tailings is used to treat a certain cyanide tailings. The main components of the cyanide tailings are: Au 3.06g / t, Ag 19.2g / t t, Fe 22.19wt%, S 2.80wt%, Cu0.36wt%, Pb 0.26wt%, Zn 0.17wt%, As 0.99wt%, SiO 2 36.0wt%, and the particle size of the cyanide tailings is -200 mesh, accounting for 85%; the method for comprehensive recovery of valuable metals from the cyanide tailings, its specific processing steps are as follows figure 1 And described in above-mentioned step A to step I, thereby can reclaim multiple valuable metals such as gold, silver, copper, zinc, lead, and gold volatilization rate is 91.8%, silver volatilization rate is 63%, copper volatilization rate is 85.1%, The lead volatilization rate was 91.8%, the zinc volatilization rate was 76.6%, the gold recovery rate was 91.2%, the silver recovery rate was 60.6%, the copper recovery rate was 83.5%, the lead recovery rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com