Thermal field emission cathode and preparation method thereof, and vacuum electronic device using same

A technology for emitting cathodes and cathode components, which is used in the manufacture of thermionic cathodes, solid thermionic cathodes of discharge tubes, electrical components, etc. problem, to achieve the effect of high emission current density, high emission current density, and improved emission capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

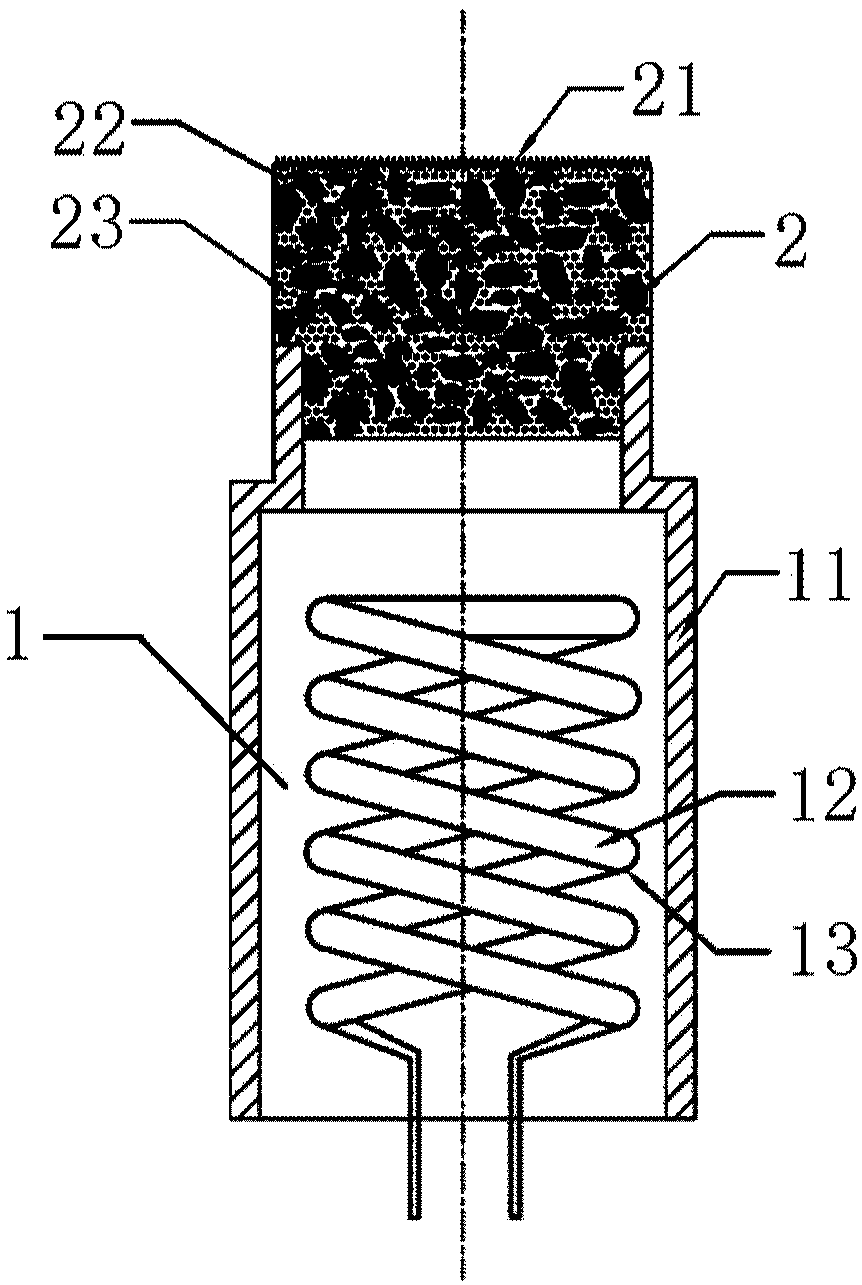

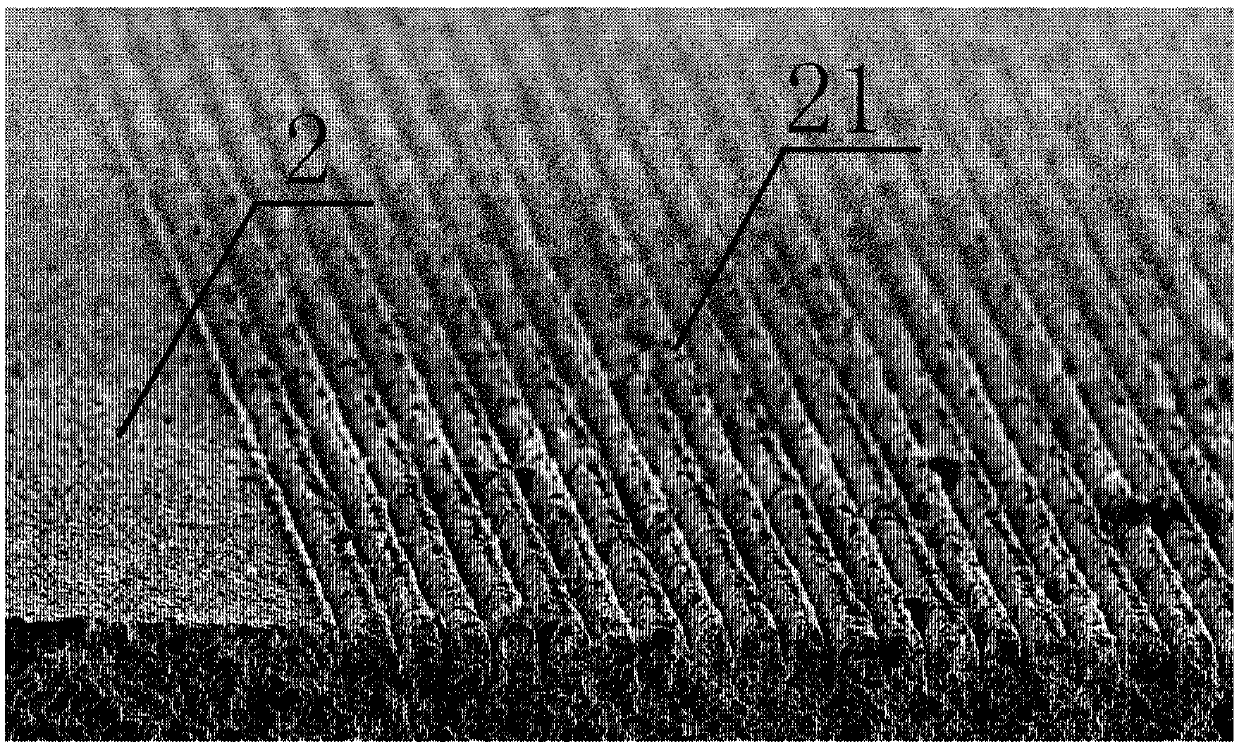

[0034]The present invention also proposes a method for preparing a thermal field emission cathode, which includes the following steps: polishing the emitting end surface of the tungsten-copper body; forming a microtip array with pores inside on the emitting end surface of the tungsten-copper body by laser ablation; Remove copper from the tungsten copper body forming the microtip array to obtain a tungsten sponge, so that the pores inside the tungsten sponge are connected with the pores inside the microtip array to obtain a tungsten sponge with a microtip array; brazing or laser welding The tungsten sponge body and the molybdenum cylinder with the microtip array form the cathode assembly; the active material impregnates the cathode assembly at high temperature to complete the preparation method of the thermal field emission cathode.

[0035] Compared with the preparation of traditional field emission cathodes, the preparation method of the present invention does not require expe...

Embodiment 1

[0065] This embodiment proposes a thermal field emission cathode and a preparation method thereof. The thermal field emission cathode is: a molybdenum cylinder and a tungsten sponge fixed on its upper surface, wherein: the upper surface of the tungsten sponge has a microtip array; the tungsten sponge The pores inside the body and the microtip array form connected pores; the connected pores are filled with active substances.

[0066] The preparation method is specifically:

[0067] Step 1. Select a tungsten copper body that meets the requirements, process and polish it. Specifically, according to the requirements of the cathode drawing, the size of the polishing removal (generally 0.1-0.3mm) is reserved, and the tungsten copper body is processed; then, the surface of the tungsten copper body that is about to be used as the emitter is polished; under normal circumstances, The size of the tungsten-copper body used for melting is relatively small. In order to facilitate processing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com