Preparation method and application of single-walled carbon nanotube flexible film capable of realizing high adsorption of organic dyes

A technology of single-wall carbon nanotubes and organic dyes, applied in chemical instruments and methods, adsorption water/sewage treatment, inorganic chemistry, etc., can solve the problems of secondary pollution adsorption materials, non-reusable, etc., achieve simple process, solve Non-reusable, high-efficiency adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

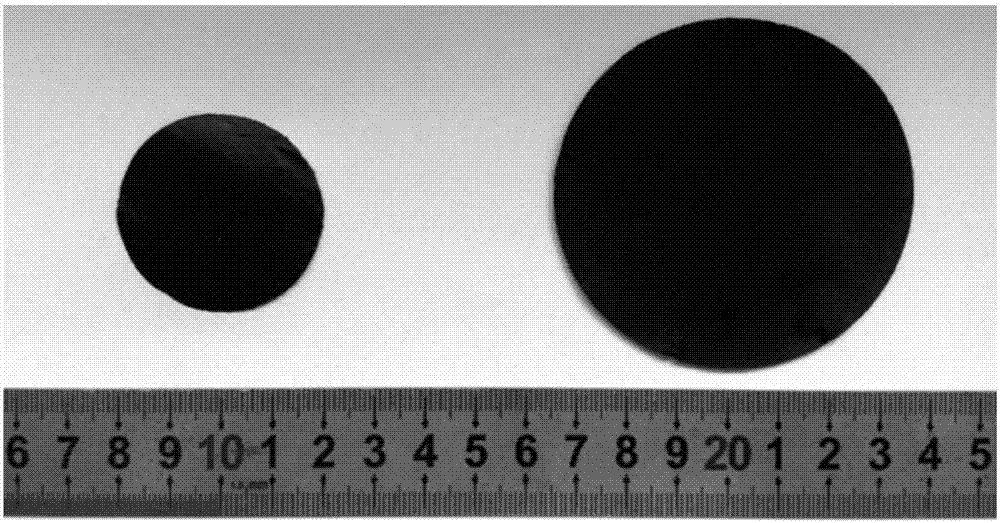

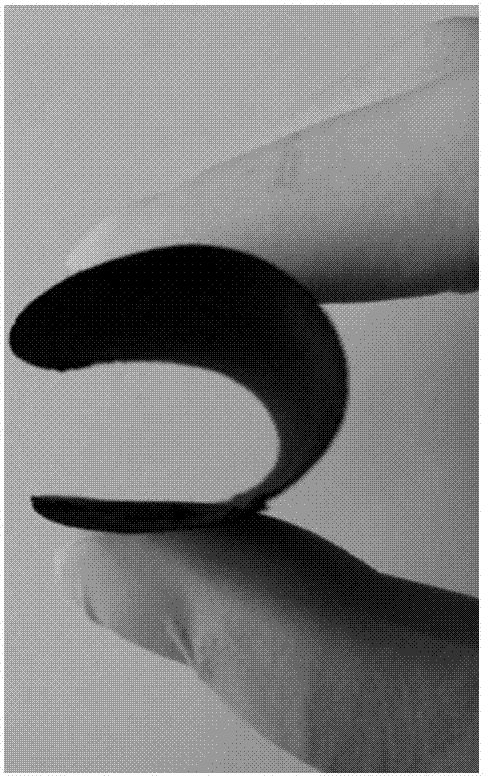

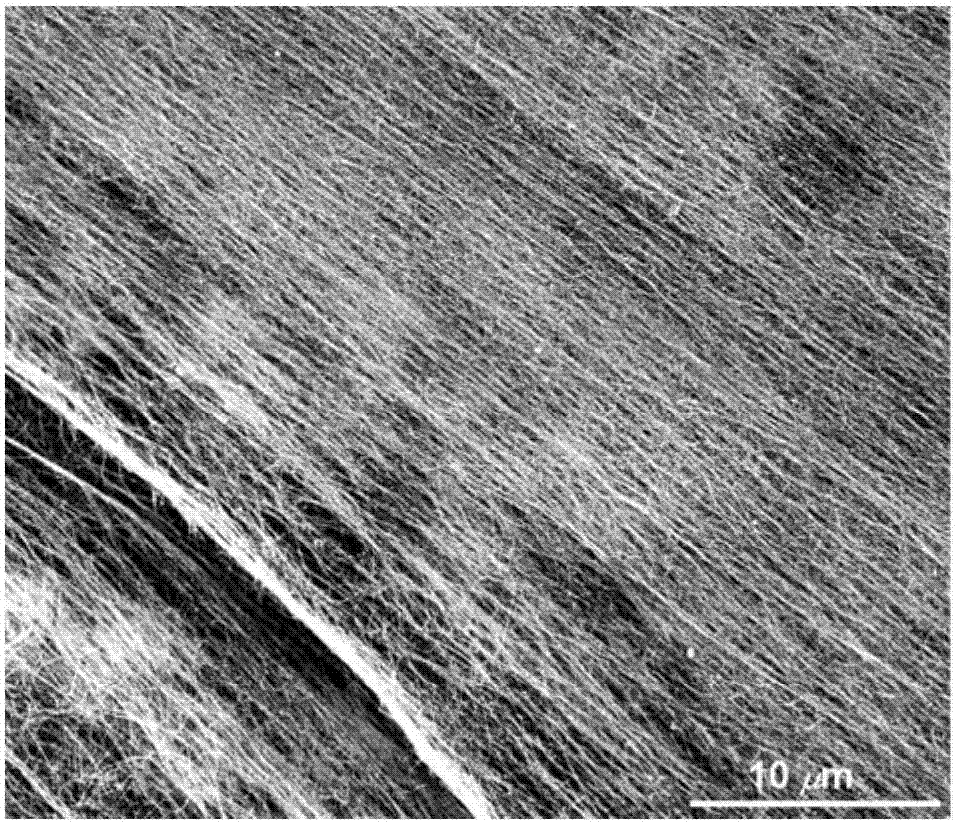

[0034] Preparation of single-walled carbon nanotube flexible film: Add 20 mg of the original sample of single-walled carbon nanotubes prepared by floating catalyst chemical vapor deposition to 200 mL of ethanol solution, and ultrasonically disperse for 30 min. Then the carbon nanotube solution obtained by dispersing is suction-filtered into a film, and film samples of different sizes can be prepared according to the diameter of the filter device used ( figure 1 ), and the film-like sample has excellent flexibility ( figure 2 ). Scanning electron microscopy, thermogravimetric analysis, low-temperature liquid nitrogen adsorption and other structural characterizations were performed on pristine single-walled carbon nanotube samples. SEM ( image 3 ) observed that the sample was pure, the length of the carbon nanotubes was long and straight, and the length of the carbon nanotubes under the scanning electron microscope was 50-70 μm ( Figure 4 ). The differential thermal analy...

Embodiment 2

[0039] Preparation of single-walled carbon nanotube flexible film: Same as Example 1, the dispersant used in this example is acetone, the average length of single-walled carbon nanotube samples is 70-80 μm, the pore diameter is concentrated in 4-8 nm, and the specific surface area is 498 m 2 / g.

[0040] Adsorption performance of flexible, recyclable, high-performance adsorption film: Same as Example 1, the dye adsorbed in this example is rhodamine B, and the adsorption capacity of the adsorption film to rhodamine B reaches 190mg g -1 , the adsorption time is 240min (such as Figure 8 ).

[0041] The desorption performance of flexible, recyclable, high-performance adsorption film: same as Example 1, the desorption amount of this adsorption film to rhodamine B is 174mg g -1 , the desorption time is 10 hours.

Embodiment 3

[0043] Preparation of single-walled carbon nanotube flexible film: Same as Example 1, the dispersant used in this example is ethylene glycol, the average length of single-walled carbon nanotube samples is 80-90 μm, the pore diameter is concentrated in 4-9 nm, and the specific surface area 657m 2 / g.

[0044] Adsorption performance of flexible, recyclable, high-performance adsorption film: Same as in Example 1, the adsorbed dye in this example is methyl orange, and the adsorption capacity of the adsorption film to methyl orange reaches 130mg g -1 , the adsorption time is 240min (such as Figure 8 ).

[0045] The desorption performance of flexible, recyclable, high-performance adsorption membrane: same as Example 1, the desorption amount of this adsorption membrane to methyl orange is 121mg g -1 , the desorption time is 10 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com