Continuous production method and device of 4-chlorophenylhydrazine hydrochloride

A technology of chlorophenylhydrazine hydrochloride and chloroaniline hydrochloride is applied in the field of continuous production method and device of p-chlorophenylhydrazine hydrochloride, and can solve the problems affecting product purity and yield, uneven mixing of materials, heavy weight, etc. The problem of slow decomposition of nitrogen salts can improve the continuity of production, improve production efficiency, and reduce high-salt wastewater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

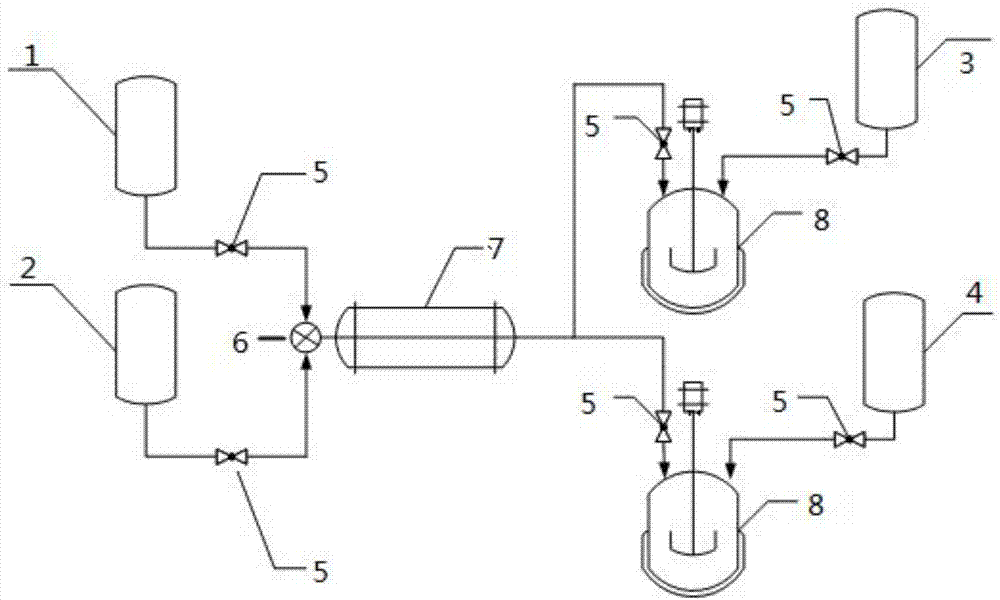

[0024] A continuous production method of p-chlorophenylhydrazine hydrochloride, comprising the following steps:

[0025] (1) prepare p-chloroaniline hydrochloride hydrochloride solution in the first batching still 1: p-chloroaniline 127.5kg, 37% hydrochloric acid 246.6kg and water 200kg; Prepare sodium nitrite solution in the second batching still 2: nitrous acid Sodium 69kg and water 140kg; P-chloroaniline hydrochloride solution and sodium nitrite solution are pumped in mixer 6 by metering pump 5, obtain mixed solution, adjust the feed ratio that mixed solution enters tubular reactor 7, parachlorine The molar ratio of aniline to sodium nitrite is 1:1.02, and the reaction temperature is 10° C. to prepare the diazonium salt intermediate;

[0026] (2) respectively drop into sodium sulfite 157.5kg and water 350kg and Raney's nickel catalyst 0.5kg in 2 reduction reactors 8 in advance, continue to pass into sulfur dioxide gas to reduction reactor 8, will the diazo that step (1) mak...

Embodiment 2

[0029] A continuous production method of p-chlorophenylhydrazine hydrochloride, comprising the following steps:

[0030] (1) prepare p-chloroaniline hydrochloride hydrochloride solution in the first batching still 1: p-chloroaniline 127.5kg, 37% hydrochloric acid 246.6kg and water 200kg; Prepare sodium nitrite solution in the second batching still 2: nitrous acid Sodium 69kg and water 140kg; P-chloroaniline hydrochloride solution and sodium nitrite solution are pumped in mixer 6 by metering pump 5, obtain mixed solution, adjust the feed ratio that mixed solution enters tubular reactor 7, parachlorine The molar ratio of aniline to sodium nitrite is 1:1.02, and the reaction temperature is 15° C. to prepare the diazonium salt intermediate;

[0031] (2) respectively drop into sodium sulfite 157.5kg and water 350kg and Raney's nickel catalyst 0.5kg in 2 reduction reactors 8 in advance, continue to pass into sulfur dioxide gas to reduction reactor 8, will the diazo that step (1) mak...

Embodiment 3

[0034] A continuous production method of p-chlorophenylhydrazine hydrochloride, comprising the following steps:

[0035] (1) prepare p-chloroaniline hydrochloride hydrochloride solution in the first batching kettle: p-chloroaniline 127.5kg, 37% hydrochloric acid 246.6kg and water 200kg; prepare sodium nitrite solution in the second batching kettle: sodium nitrite 69kg and water 140kg; p-Chloroaniline hydrochloride solution and sodium nitrite solution are pumped into the mixer to obtain a mixed solution, adjust the feed ratio of the mixed solution into the tubular reactor, the mol ratio of p-chloroaniline and sodium nitrite The ratio is 1:1.12, the reaction temperature is 10°C, and the diazonium salt intermediate is obtained;

[0036] (2) respectively drop into sodium sulfite 157.5kg and water 350kg and Raney's nickel catalyst 0.5kg in 2 reduction reactors 8 in advance, continue to pass into sulfur dioxide gas to reduction reactor 8, will the diazo that step (1) makes The salt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com