Photoinitiator composition suitable for UV-LED light source

A technology of UV-LED and photoinitiator, which is applied in the direction of coating, etc., can solve the problems of unsatisfactory curing effect, large amount of photoinitiator, and poor surface drying, etc., to achieve high initiating activity, long light absorption wavelength, and small dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Photoinitiator composition A: isopropylthioxanthone+methyl benzoylformate+2,4,6-trimethylbenzoyl-diphenylphosphine oxide

[0043] Add 1g of isopropylthioxanthone and 1g of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide into 2g of methyl benzoylformate and ultrasonically dissolve to form photoinitiator composition A , and then formulated into a photopolymerization system according to Table 1, coated on a glass sheet with a wire bar coater, and exposed according to the conditions in Table 2 to obtain a photocurable coating material.

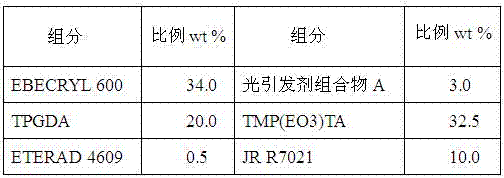

[0044] Table 1: Specific composition and ratio of photocuring system

[0045]

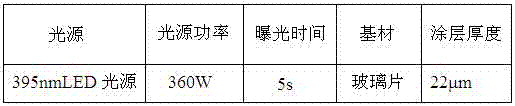

[0046] Table 2: Coating Thickness and Exposure Conditions

[0047]

[0048] The obtained light-cured coating was well cured overall, had no peculiar smell, had a smooth and uniform surface, and had a pencil hardness of 2H, indicating that the photoinitiator composition A had good photoinitiation activity for a film thickness coating of 22 μm under a 395nm ...

Embodiment 2

[0050] Photoinitiator composition B: 2,4-diethylthioxanthone + methyl benzoylformate + ethyl 2,4,6-trimethylbenzoylphosphonate

[0051] Add 1g of 2,4-diethylthioxanthone and 1g of ethyl 2,4,6-trimethylbenzoylphosphonate into 2g of methyl benzoylformate and ultrasonically dissolve to form a photoinitiator combination Matter B, then formulate a photopolymerization system according to Table 3, apply it on a glass sheet with a wire bar coater, and expose according to the conditions in Table 2 to obtain a photocurable coating material.

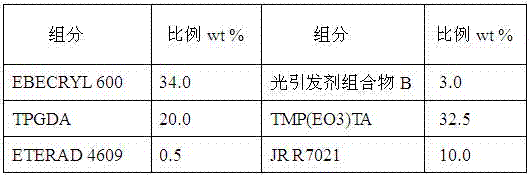

[0052] Table 3: Specific composition and ratio of photocuring system

[0053]

[0054] The obtained photocurable coating was well cured overall, with almost no peculiar smell, smooth and uniform surface, and a pencil hardness of 2H, indicating that the photoinitiator composition B had good photoinitiation activity for a film thickness coating of 22 μm under a 395nm LED light source.

Embodiment 3

[0056] Photoinitiator composition B: 2,4-diethylthioxanthone + methyl benzoylformate + ethyl 2,4,6-trimethylbenzoylphosphonate

[0057] Add 1g of 2,4-diethylthioxanthone and 1g of ethyl 2,4,6-trimethylbenzoylphosphonate into 2g of methyl benzoylformate and ultrasonically dissolve to form a photoinitiator combination Matter B, then formulate a photopolymerization system according to Table 3, apply it on a glass sheet with a wire bar coater, and expose according to the conditions in Table 4 to obtain a photocurable coating material.

[0058] Table 4: Coating Thickness and Exposure Conditions

[0059]

[0060] The obtained light-cured coating was well cured overall, with almost no peculiar smell, smooth and uniform surface, and a pencil hardness of 2H, indicating that the photoinitiator composition B had good photoinitiation activity for a film thickness coating of 22 μm under a 385nm LED light source.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com