Dual-cured glass ink and preparation method thereof

A glass ink and dual curing technology, applied in the field of ink, can solve the problems of high temperature process operation difficulties, energy waste, etc., achieve high reactivity, improve overall performance, and solve the effects of poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A dual-cured glass ink, comprising the following raw materials in parts by weight:

[0053] 80 parts of dual-cure silicone resin matrix;

[0054] 0 parts of photocurable resin;

[0055] Photocurable monomer diluent: 20 parts of photocurable monomer diluent composed of trimethylolpropane triacrylate, tripropylene glycol diacrylate, and butyl acrylate in a mass ratio of 1:3:3;

[0056] Amine curing agent: 593E 15 parts;

[0057] Pigment 0 parts;

[0058] Photoinitiator: 2 parts of 184 and 810 in a mass ratio of 2:3.

specific Embodiment 2-6

[0059] Specific embodiment 2-6, other are with specific embodiment 1, difference is following table:

[0060]

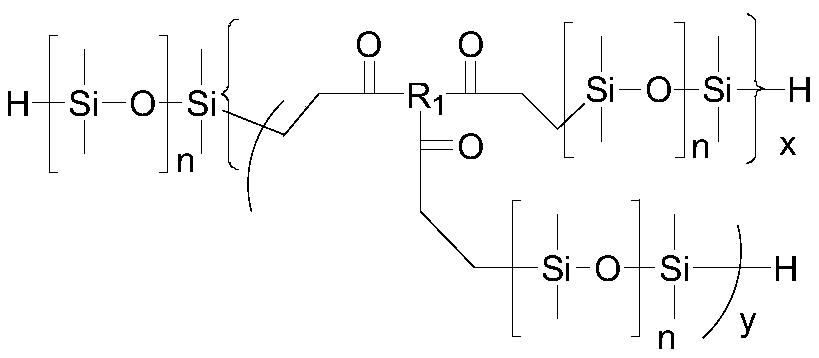

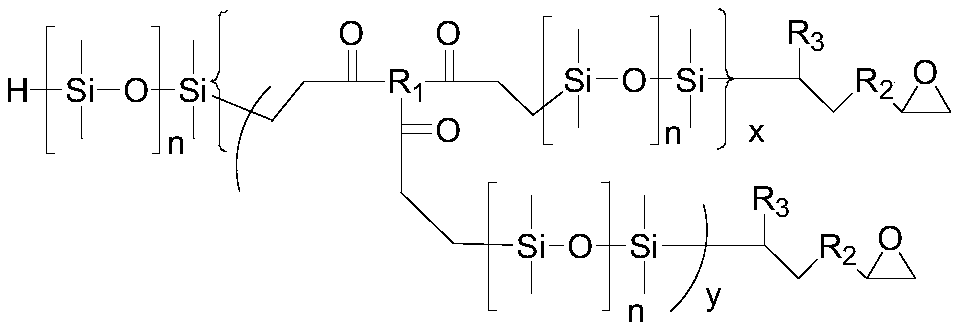

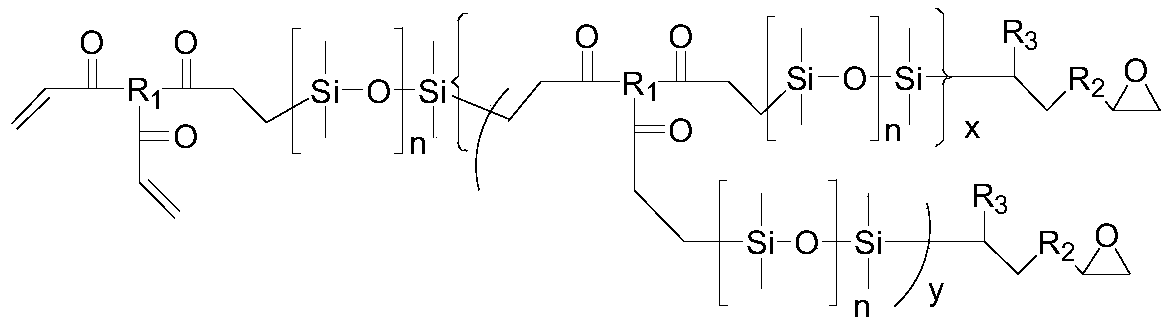

[0061] The dual-cure silicone resin used in the above-mentioned embodiments 1-6 is prepared by the following method:

[0062] (1) Dissolve 1 part of double-terminal hydrogen-containing siloxane in 80 parts of tetrahydrofuran, 0.3 parts of trimethylolpropane triacrylate, 1 wt% of 2,6-di-tert-butyl-p-methylphenol, 10 -5 Parts of chloroplatinic acid, dissolved in 10 parts of tetrahydrofuran and added to the constant pressure dropping funnel, controlled dropping speed, stirred, reacted at 70°C for 5 hours, distilled off the solvent under reduced pressure, added 50 parts of toluene, excess sodium bicarbonate and 10 parts Deionized water, stirred at 60°C for 3h, separated the water phase, took the organic layer, and distilled off the solvent under reduced pressure to obtain a single-terminal hydrogen-containing polysiloxane (IR: 1640cm -1 、811cm -1 :-C=C-disappears), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com