Electrospinning-based flexible tensile strain sensor with spiral wound structure

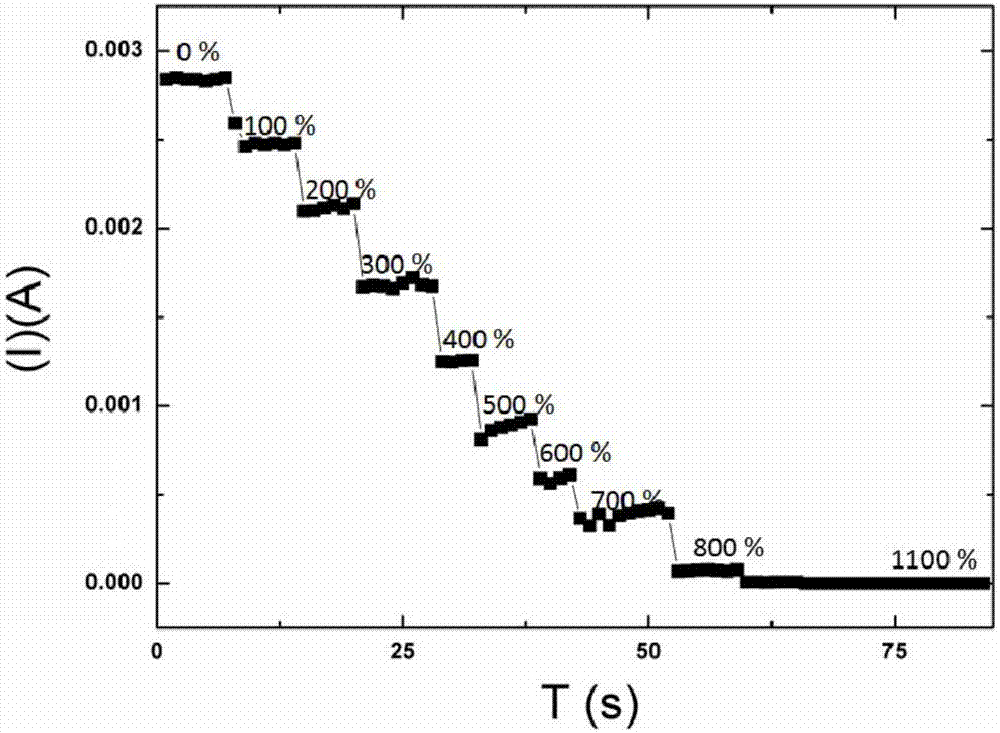

A technology of tensile strain and helical winding, which is applied in the direction of using electric/magnetic devices to transmit sensing components, textiles and papermaking, fiber chemical characteristics, etc., can solve the problems of inability to provide electrical signal response, decline in electrical conductivity, etc., and achieve strain tolerance Wide range, high tensile recovery, and the effect of ensuring electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

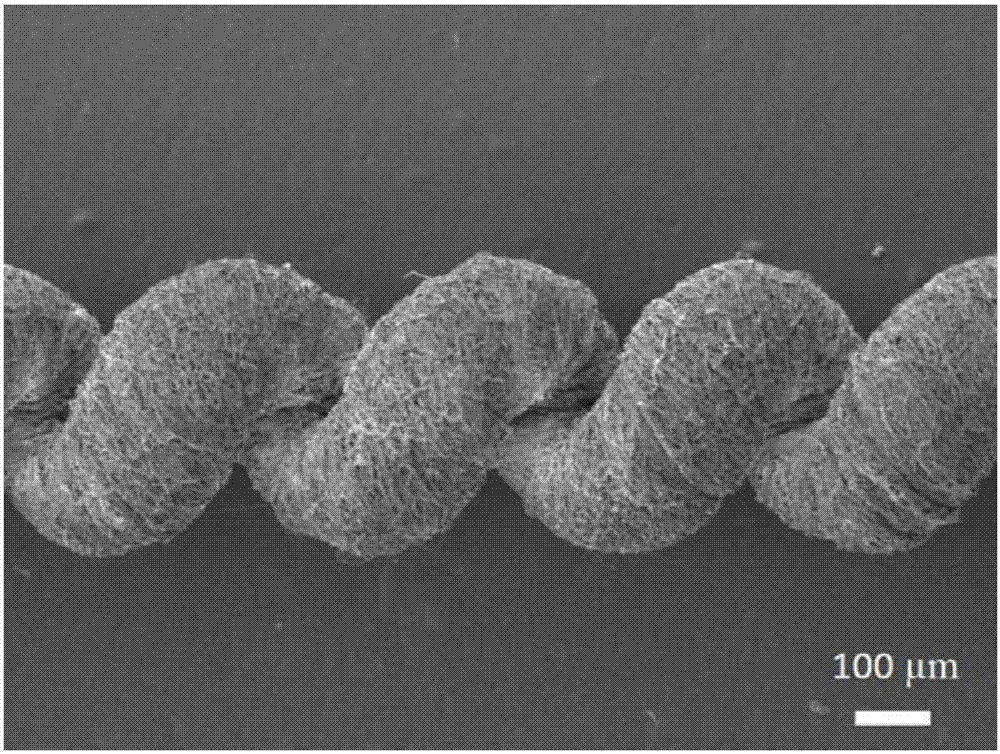

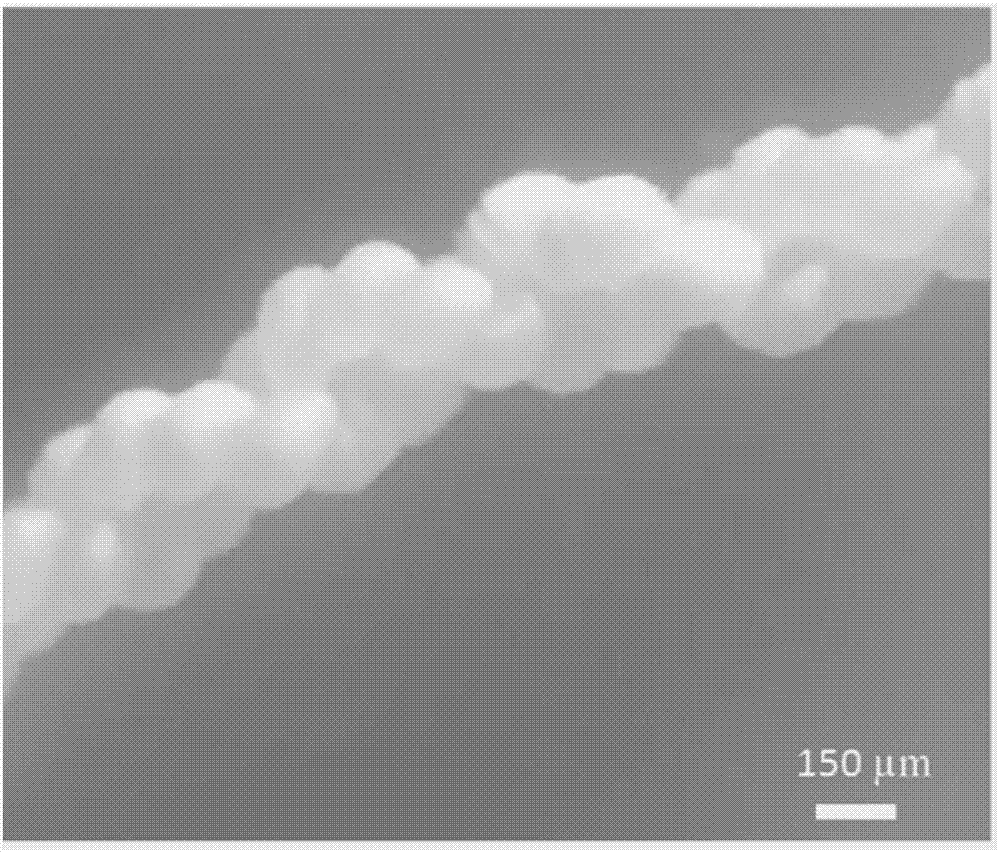

[0034] A method for preparing a flexible and stretchable strain sensor based on electrospinning helical winding structure, comprising the following steps:

[0035] (1) Preparation of conductive nanofiber film by electrospinning: mix 1.2g polyurethane (PU), 3.9g N-N dimethylformamide and 3.9g acetone, heat and stir at 40°C until uniform and transparent to obtain a uniform spinning precursor solution, and spin The silk precursor solution is injected into the liquid storage mechanism of the electrospinning device, the spinning voltage is 13 kV, the spinning distance is 8 cm, the air humidity is 45%, and the spinning time is 10 minutes, that is, the insulation is obtained on the collector electrode of the electrospinning device. Nanofiber membrane, the obtained insulating nanofiber membrane is immersed in a graphene solution (solvent is DMF) after in-situ wetting and loading graphene, and then the sample is naturally dried to obtain a conductive nanofiber membrane;

[0036] (2) Pr...

Embodiment 2

[0040] A method for preparing a flexible and stretchable strain sensor based on electrospinning helical winding structure, comprising the following steps:

[0041] (1) Preparation of conductive nanofiber film by electrospinning: mix 1.2g polyurethane (PU), 3.9g N-N dimethylformamide and 3.9g acetone, heat and stir at 40°C until uniform and transparent to obtain a uniform spinning precursor solution, and spin The silk precursor solution is injected into the liquid storage mechanism of the electrospinning device, the spinning voltage is 13 kV, the spinning distance is 8 cm, the air humidity is 45%, and the spinning time is 10 minutes, that is, the insulation is obtained on the collector electrode of the electrospinning device. Nanofiber membrane; Dissolve 2.542g of sulfosalicylic acid in 50ml of deionized water, then add 1.8626g of aniline into it, and stir it thoroughly as solution A, dissolve 4.564g of ammonium persulfate in 50ml of deionized water, and stir it fully As soluti...

Embodiment 3

[0047] A method for preparing a flexible and stretchable strain sensor based on electrospinning helical winding structure, comprising the following steps:

[0048] (1) Preparation of conductive nanofiber film by electrospinning: mix 1.2g polyurethane (PU), 3.9g N-N dimethylformamide and 3.9g acetone, heat and stir at 40°C until uniform and transparent to obtain a uniform spinning precursor solution, and spin The silk precursor solution is injected into the liquid storage mechanism of the electrospinning device, the spinning voltage is 13 kV, the spinning distance is 8 cm, the air humidity is 45%, and the spinning time is 10 minutes, that is, the insulation is obtained on the collector electrode of the electrospinning device. Nanofiber membrane; mix 0.3ml hydrochloric acid, 1.2ml EDOT, and 60ml deionized water, and record it as solution ①; mix 2.16g ammonium persulfate and 30ml deionized water, and record it as solution ②. After stirring with a magnetic stirrer at room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com