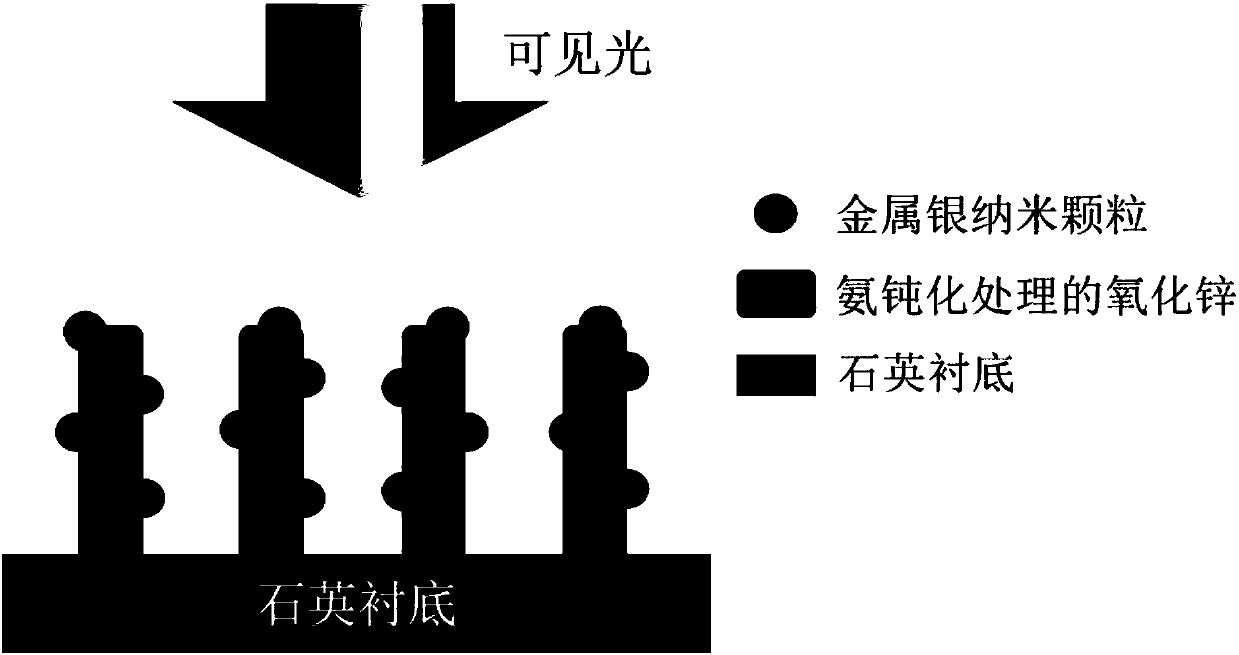

Method for synergistically enhancing photocatalysis of ZnO through plasmon and ammonia passivation

A plasmonic and zinc oxide technology, applied in the field of photocatalysis, achieves the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation conditions: room temperature, class 100 clean room;

[0035] The specific steps are:

[0036] (1) Choose a zinc oxide (ZnO) substrate in the (100) crystal phase, with a volume of 10×10×0.5mm 3 ;

[0037] (2) Passivate the zinc oxide substrate with high-pressure ammonia, pass through 0.4MPa high-purity ammonia gas, and heat it in a high-purity ammonia gas environment at 300°C for 30 hours;

[0038] (3) Take out the zinc oxide after ammonia passivation, and let it cool naturally for 12 hours to room temperature;

[0039] (4) Vacuum thermal evaporation treatment is performed on the zinc oxide after ammonia passivation to form a metal nano film;

[0040] (5) Perform annealing treatment on the vapor-deposited zinc oxide, pass high-purity nitrogen gas, and control the flow rate of nitrogen gas to 150ml / min; anneal at 350°C for 5 minutes in a nitrogen environment to form metal nanoparticles. Cool in the tube after power off for 1 hour.

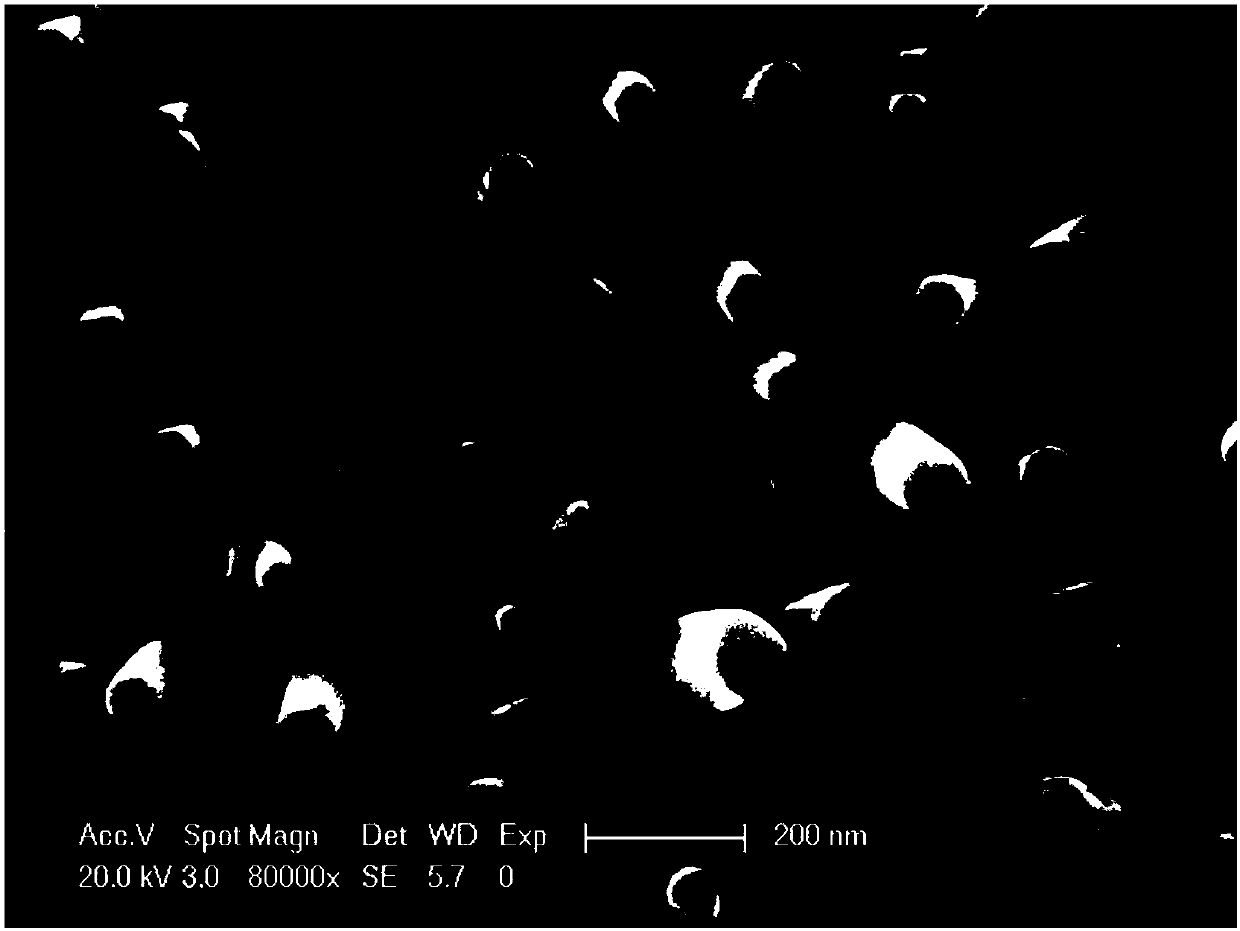

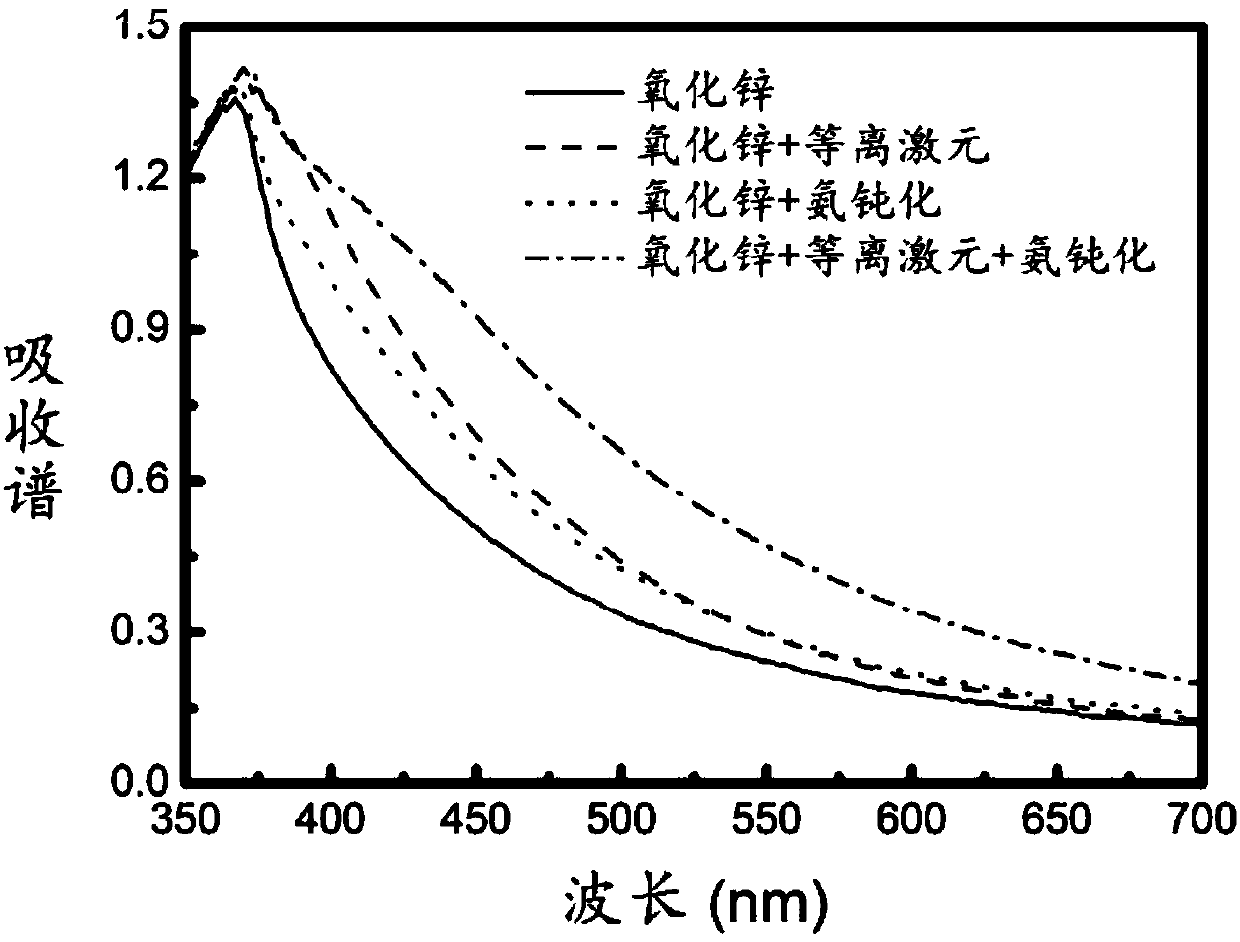

[0041] We characterize...

Embodiment 2

[0043] Preparation conditions: room temperature, class 100 clean room;

[0044] The specific steps are:

[0045] (1) Choose a zinc oxide (ZnO) substrate in the (100) crystal phase, with a volume of 10×10×0.5mm 3 ;

[0046] (2) Passivate the zinc oxide substrate with high-pressure ammonia, pass through 0.8MPa high-purity ammonia gas, and heat it in a high-purity ammonia gas environment at 350°C for 24 hours;

[0047] (3) Take out the zinc oxide after ammonia passivation, and let it cool naturally for 12 hours to room temperature;

[0048] (4) Vacuum thermal evaporation treatment is performed on the zinc oxide after ammonia passivation to form a metal nano film;

[0049] (5) Perform annealing treatment on the evaporated zinc oxide, pass high-purity nitrogen gas, and control the flow rate of nitrogen gas to 100-ml / min;

[0050] Annealing at 400° C. for 4 minutes in a nitrogen environment to form metal nanoparticles. Cool in the tube after power off for 1 hour.

Embodiment 3

[0052] Preparation conditions: room temperature, class 100 clean room;

[0053] The specific steps are:

[0054](1) Choose a zinc oxide (ZnO) substrate in the (100) crystal phase, with a volume of 10×10×0.5mm 3 ;

[0055] (2) Passivate the zinc oxide substrate with high-pressure ammonia, pass through 0.6MPa high-purity ammonia gas, and heat in a high-purity ammonia gas environment at 400°C for 20 hours;

[0056] (3) Take out the zinc oxide after ammonia passivation, and let it cool naturally for 12 hours to room temperature;

[0057] (4) Vacuum thermal evaporation treatment is performed on the zinc oxide after ammonia passivation to form a metal nano film;

[0058] (5) Perform annealing treatment on the vapor-deposited zinc oxide, and anneal at 400° C. for 3 minutes in a nitrogen environment to form metal nanoparticles. Cool in the tube after power off for 1 hour.

[0059] For the materials prepared in Examples 2 and 3, the activity of the photocatalyst was characterized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com