A kind of antibacterial environment-friendly negative ion quartz stone countertop material and preparation method thereof

A quartz stone and negative ion technology, applied in the field of quartz stone countertop materials for interior decoration, can solve the problems of insufficient negative ion yield, reduced performance, poor performance of negative ion ceramic tiles, etc. The effect of the proliferation of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

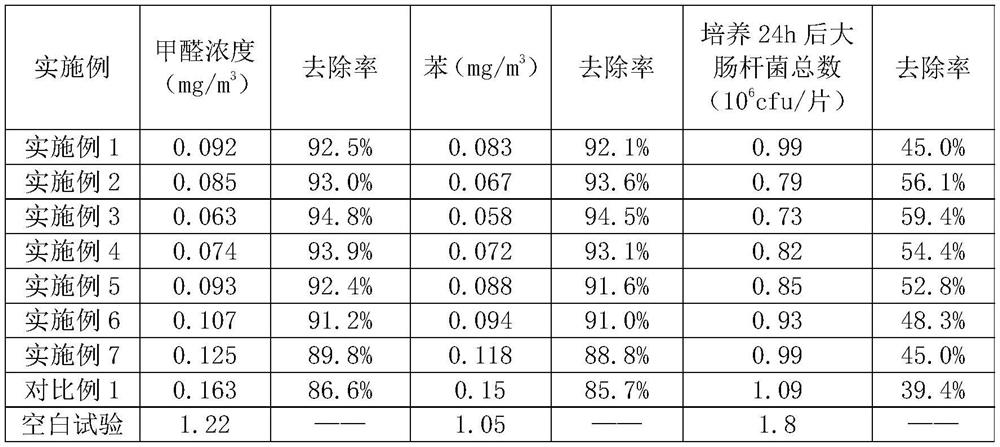

Examples

Embodiment 1

[0031] Example 1: Weigh the following raw materials according to the mass ratio: 10 parts of diatomite, 35 parts of clay, 18 parts of high-alumina sand, 2 parts of wollastonite, 4 parts of lime, 10 parts of food-grade unsaturated resin, 15 parts of quartz stone Parts, pre-mixed in a rotary mixer, then add water, send it to a ball mill for ball milling, sieve to remove iron, dry the raw material of the quartz stone countertop material body after iron removal to obtain a brick body powder, and make the brick body powder The body powder is pressed and molded, dried to obtain a brick, and then fired for the first time to obtain a green body; first weigh 4 parts of titanium dioxide nanotubes and 4 parts of nano anion powder according to the mass ratio, and the average diameter of the titanium dioxide nanotubes It is 80nm, the surface average pore size is 15nm, the particle size distribution of nano-anion powder is 30-150nm, its particle size distribution D10=47nm, D90=128nm, first d...

Embodiment 2

[0032] Example 2: Weigh the following raw materials according to the mass ratio: 15 parts of diatomite, 40 parts of clay, 23 parts of high-alumina sand, 4 parts of wollastonite, 7 parts of lime, 14 parts of food-grade unsaturated resin, 17 parts of quartz stone Parts, pre-mixed in a rotary mixer, then add water, send it to a ball mill for ball milling, sieve to remove iron, dry the raw material of the quartz stone countertop material body after iron removal to obtain a brick body powder, and make the brick body powder The body powder is pressed and molded, dried to obtain a brick, and then fired for the first time to obtain a green body; first weigh 6 parts of titanium dioxide nanotubes and 6 parts of nano anion powder according to the mass ratio, and the average diameter of the titanium dioxide nanotubes It is 80nm, the surface average pore size is 15nm, the particle size distribution of nano-anion powder is 30-150nm, its particle size distribution D10=47nm, D90=128nm, first d...

Embodiment 3

[0033] Example 3: Weigh the following raw materials according to the mass ratio: 20 parts of diatomite, 45 parts of clay, 28 parts of high-alumina sand, 5 parts of wollastonite, 10 parts of lime, 16 parts of food-grade unsaturated resin, 20 parts of quartz stone Parts, pre-mixed in a rotary mixer, then add water, send it to a ball mill for ball milling, sieve to remove iron, dry the raw material of the quartz stone countertop material body after iron removal to obtain a brick body powder, and make the brick body powder The body powder is pressed and molded, dried to obtain a brick, and then fired for the first time to obtain a green body; first weigh 8 parts of titanium dioxide nanotubes and 8 parts of nano-anion powder according to the mass ratio, and the average diameter of the titanium dioxide nanotubes It is 80nm, the surface average pore size is 15nm, the particle size distribution of nano-anion powder is 30-150nm, its particle size distribution D10=47nm, D90=128nm, first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com