Loaded TiO2 foam ceramic, and preparation method and application thereof

A technology of foam ceramics and polyurethane foam, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of high raw material requirements, reduced porosity, and high energy consumption, and achieves good photocatalytic effects and preparation methods The effect of simplicity and high photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

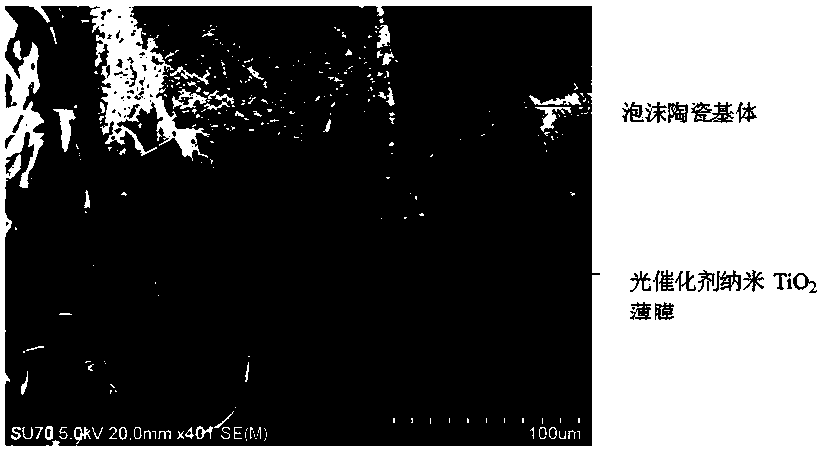

[0033] A loaded TiO 2 The preparation method of ceramic foam, concrete steps are:

[0034] (1) Preparation of nano-titanium dioxide precursor;

[0035] (2) Pretreatment of polyurethane foam: put polyurethane foam (pore size 0.3~0.8mm) in 10~20wt% NaOH solution, treat at 60°C for 1~2h, rub and clean repeatedly, and then place the foam in modifier Soak in medium for 3~12h, dry for later use, wherein the modifier is CMC or PVA;

[0036] (3) Preparation of primary slurry: Mix fused alumina powder, aluminum dihydrogen phosphate solution and distilled water to make slurry, so that the solid phase content in the slurry is 60~80wt%, and the content of aluminum dihydrogen phosphate is between 10 ~30wt%;

[0037] (4) One-time slurrying: put the pretreated polyurethane foam in the slurry, let it stretch freely and continuously squeeze, stir and knead to coat the slurry evenly on the polyurethane foam, and remove the excess slurry to obtain the slurry Biscuit;

[0038] (5) Drying of ...

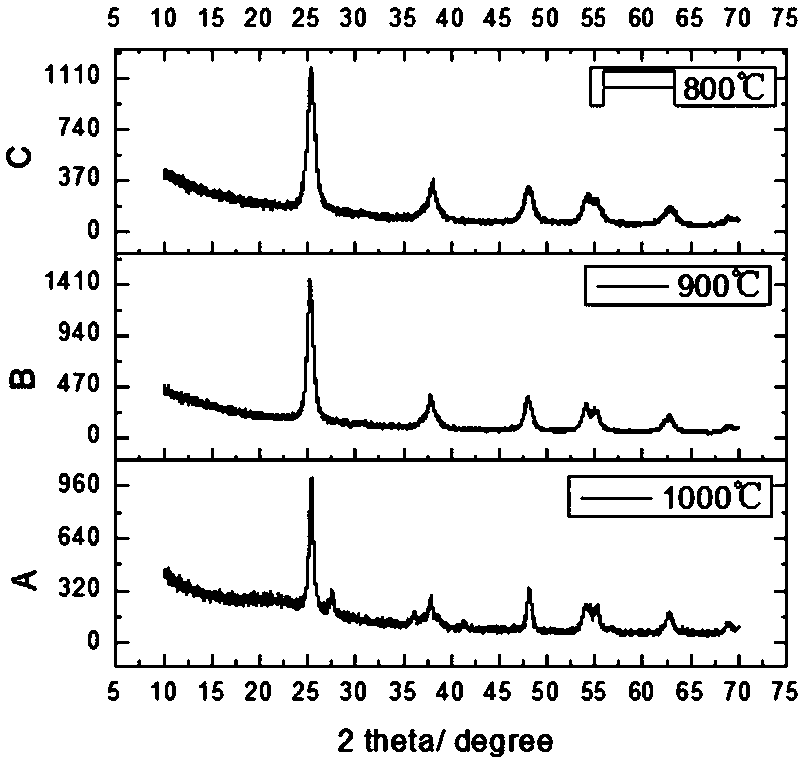

Embodiment 1

[0049] A loaded TiO 2 The preparation method of ceramic foam, concrete steps are:

[0050] (1) Preparation of nano-titanium dioxide precursor:

[0051] a. Dissolve 10g of TiCl in an ice-water bath 4 Drop into 1000mL of vigorously stirred pure water at a rate of 1 drop / s to prepare 0.05mol / L TiCl 4 solution;

[0052] b. Adjust the pH value of the solution to 8 with ammonia water with a mass fraction of 5%, to obtain a precipitate of orthotitanic acid, and wash the precipitate with deionized water 10 times;

[0053] c. Disperse the precipitate in 200mL of hydrogen peroxide solution with a mass concentration of 10%, stir at room temperature for 1 hour, and add 20g of nano-SiO with a mass concentration of 30% 2 Sol, continue to stir for 30 minutes, get the precursor of nano-titanium dioxide;

[0054] (2) Pretreatment of polyurethane foam: put polyurethane foam with a pore size of 0.4mm 100×50×10mm in 15 wt% NaOH solution, treat it at 60°C for 1 h, rub and clean it repeatedly,...

Embodiment 2

[0062] The content of aluminum dihydrogen phosphate in step (3) of Example 1 was adjusted to 30 wt%, and the other conditions were the same as in Example 1, that is, the photocatalytic foam ceramic core material sample 2 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com