Method for oligomerization of alpha-olefin based on microchannel reaction

A technology of microchannel reaction and microchannel reactor, which is applied in the synthesis field of fully synthetic lubricating base oil, can solve the problems of many by-products, low pentamer selectivity, long residence time, etc., and achieve improved efficiency and good solubility , the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Use organic acid to modify aluminum trichloride: mix acetic acid and aluminum trichloride at a molar ratio of 0.6:1, and use 1,2-dichloroethane as a solvent, react at room temperature for 30 minutes, and the state of the reaction system is no obvious Particles, homogeneously dispersed yellow-brown liquid, the mass concentration of aluminum trichloride is 0.25g / ml.

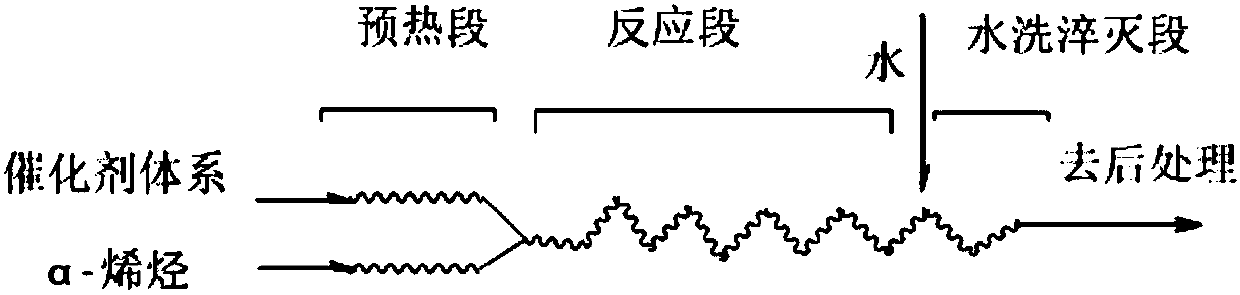

[0040] The microchannel reaction process used is as follows: figure 1 As shown, the entire device includes a catalytic system and an olefin feed preheating section, a strong mixing reaction section, and a water washing and quenching section. Among them, the reactor is made of ceramic material, the inner diameter of the smallest part of the channel is 0.8mm, and the spherical structure, the liquid holding volume of the strong mixing reaction section is 100ml, and the residence time of the reaction section can be calculated according to the flow rate and the liquid holding volume.

[0041] In the α-olefin pol...

Embodiment 2

[0044] The preparation of the homogeneous aluminum trichloride catalyst system and the microchannel reaction process used are as in Example 1.

[0045] 1-decene is used as the raw material, the reaction temperature is 80°C, the mass flow rate ratio of the feed metering pump of the catalytic system to the 1-decene feed pump is 1:21, and the residence time in the reaction section is 200s.

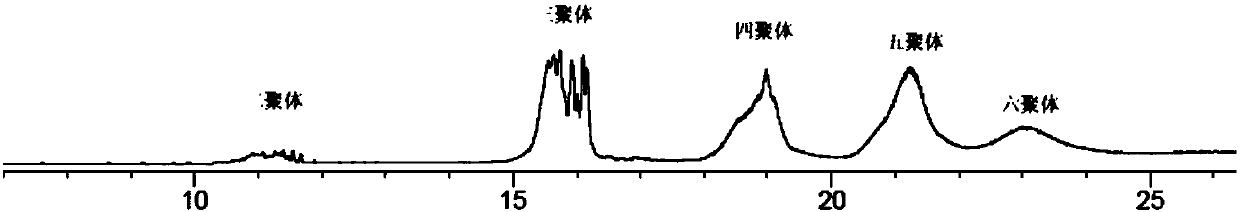

[0046] The product can be detected by gas chromatography after being neutralized and washed. At this time, the conversion rate of the product is 93%, and the selectivity of trimers, tetramers and pentamers, which are ideal components of lubricating base oil, is 92%.

Embodiment 3

[0048] The preparation of the homogeneous aluminum trichloride catalyst system and the microchannel reaction process used are as in Example 1. Except changing the molar ratio of acetic acid and aluminum trichloride to 1:1. After the modification reaction of aluminum trichloride with organic acid is completed, the catalytic system becomes a clear and transparent liquid.

[0049] 1-decene is used as the raw material, the reaction temperature is 80°C, the mass flow rate ratio of the feed metering pump of the catalytic system to the 1-decene feed pump is 1:15, and the residence time in the reaction section is 300s.

[0050] The product can be detected by gas chromatography after neutralization and washing. At this time, the conversion rate of the product is 76%, and the selectivity of trimers, tetramers and pentamers, which are ideal components of lubricating base oil, is 93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com