Environment-friendly copper and copper alloy plate strip surface hot-dip tinning method

A copper alloy plate, hot-dip plating technology, applied in the hot-dip plating process, metal material coating process, coating, etc., can solve the problems of low production efficiency, damage, uneven coating thickness distribution, etc., to improve production Efficiency, guaranteed uniformity, and quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

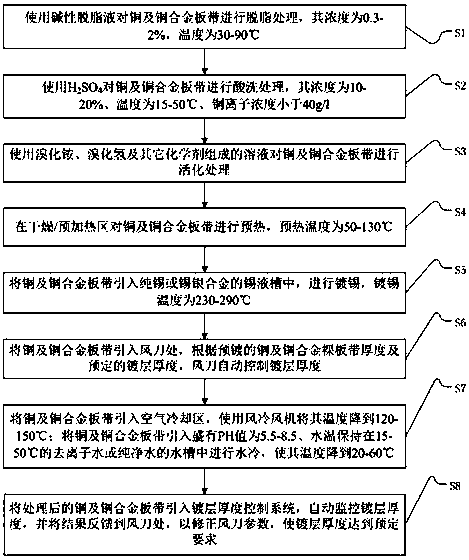

Image

Examples

Embodiment 1

[0066] An environment-friendly production process for hot-dip tinning of metal strips, comprising the following steps:

[0067] (1) Uncoil, place the pre-plated 0.1mm thick and 370mm wide C70250 copper alloy strip on the uncoiler for unwinding.

[0068] (2) Introduce the C70250 copper alloy strip treated in step (1) into the front S roll, and keep the tension of the strip at 15Mpa.

[0069] (3) Degreasing, degreasing and cleaning the C70250 copper alloy coil after the treatment in step (2) with an alkaline degreasing solution composed of silicates and non-ionic surfactants, keeping the concentration of the degreasing solution at 1-2% , The temperature is 50-80 ℃. Remove the oil on the surface of the copper strip through step (3) to ensure that the tin layer is uniform and smooth during hot-dip tinning.

[0070] (4) Cold rinsing. The copper and copper alloy strips treated in step (3) are cold-rinsed with deionized water or pure water, and the pH value of the cleaning water is...

Embodiment 2

[0089] An environment-friendly production process for hot-dip tinning of metal strips, comprising the following steps:

[0090] (1) Uncoil, place the pre-plated 1.5mm thick and 200mm wide C42500 copper alloy strip on the uncoiler for unwinding.

[0091] (2) The C42500 copper alloy strip treated in step (1) is introduced into the front S roller, and the tension of the strip is kept at 30Mpa.

[0092](3) Degreasing, degreasing and cleaning the C42500 copper alloy coil after the treatment in step (2) with an alkaline degreasing solution composed of silicates and non-ionic surfactants, keeping the concentration of the degreasing solution at 1-2% , The temperature is 50-80 ℃. Remove the oil on the surface of the copper strip through step (3) to ensure that the tin layer is uniform and smooth during hot-dip tinning.

[0093] (4) Cold rinsing. The copper and copper alloy strips treated in step (3) are cold-rinsed with deionized water or pure water, and the pH value of the cleaning ...

Embodiment 3

[0112] An environment-friendly production process for hot-dip tinning of metal strips, comprising the following steps:

[0113] (1) Uncoil, place the pre-plated 1.2mm thick and 370mm wide C10100 (TU00) copper strip coil on the uncoiler for unwinding.

[0114] (2) Introduce the C10100 (TU00) copper strip coil treated in step (1) into the front S roller, and keep the coil tension at 20Mpa.

[0115] (3) Degreasing, degreasing and cleaning the C10100 (TU00) copper coils treated in step (2) with an alkaline degreasing solution composed of silicates and non-ionic surfactants, keeping the concentration of the degreasing solution at 1- 2%, the temperature is 50-80°C. Remove the oil on the surface of the copper strip through step (3) to ensure that the tin layer is uniform and smooth during hot-dip tinning.

[0116] (4) Cold rinsing. The copper and copper alloy strips treated in step (3) are cold-rinsed with deionized water or pure water, and the pH value of the cleaning water is kep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com