Process for treating surface of stainless steel tube

A stainless steel tube and surface treatment technology, applied in the direction of metal material coating process, etc., can solve the problems of low gloss, pollution, high labor intensity of mechanical method, etc., and achieve the effect of high surface finish and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

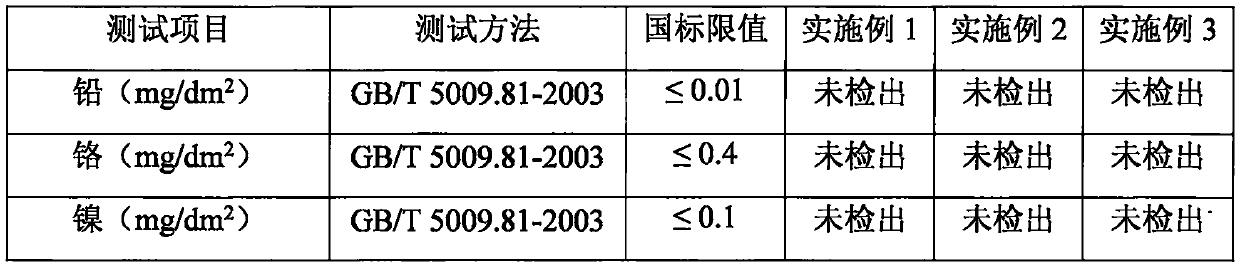

Examples

Embodiment 1

[0023] A surface treatment process for stainless steel pipes includes the following steps:

[0024] Step S1: Outer surface cleaning treatment: Place the stainless steel tube per liter with 20 parts by mass of sodium silicate, 40 parts by mass of sodium carboxymethyl cellulose, 20 parts by mass of potassium carbonate, 20 parts by mass of citric acid fatty acid glyceride, 2 parts by mass Parts of ethylenediamine polyoxyethylene polyoxypropylene block polyether, 20 parts by mass of sodium sulfate, 2 parts by mass of disodium ethylenediaminetetraacetate, 20 parts by mass of sodium percarbonate, 15 parts by mass of lauryl alcohol polyoxyethylene ether Sodium sulfate and 3 parts by mass of trimethylsilyl magnesium chloride are dissolved in the first mixed solution formed by dissolving in deionized water, and the first mixed solution is treated with ultrasonic vibration for 30 minutes. The temperature of the first mixed solution is maintained at 60°C, and then the stainless steel tube is...

Embodiment 2

[0030] A surface treatment process for stainless steel pipes includes the following steps:

[0031] Step S1: External surface cleaning treatment: The stainless steel tube is placed in a liter of 30 parts by mass of sodium silicate, 35 parts by mass of sodium carboxymethyl cellulose, 35 parts by mass of potassium carbonate, 18 parts by mass of citric acid fatty acid glycerides, 1 mass Parts of ethylenediamine polyoxyethylene polyoxypropylene block polyether, 5 parts by mass of sodium sulfate, 10 parts by mass of disodium ethylenediaminetetraacetate, 5 parts by mass of sodium percarbonate, 18 parts by mass of lauryl alcohol polyoxyethylene ether Sodium sulfate and 1 part by mass of trimethylsilyl magnesium chloride are dissolved in the first mixed solution formed by dissolving in deionized water, and the first mixed solution is treated with ultrasonic vibration for 90 minutes. The temperature of the first mixed solution is maintained at 60°C, and then the stainless steel tube is mov...

Embodiment 3

[0037] A surface treatment process for stainless steel pipes includes the following steps:

[0038] Step S1: External surface cleaning treatment: The stainless steel tube is placed in a liter of 50 parts by mass of sodium silicate, 30 parts by mass of sodium carboxymethyl cellulose, 50 parts by mass of potassium carbonate, 15 parts by mass of citric acid fatty acid glyceride, and 5 parts by mass. Parts of ethylenediamine polyoxyethylene polyoxypropylene block polyether, 15 parts by mass of sodium sulfate, 5 parts by mass of disodium ethylenediaminetetraacetate, 10 parts by mass of sodium percarbonate, 20 parts by mass of lauryl alcohol polyoxyethylene ether Sodium sulfate and 5 parts by mass of trimethylsilyl magnesium chloride are dissolved in the first mixed solution formed by dissolving in deionized water, and ultrasonically shaking for 60 minutes. The temperature of the first mixed solution is maintained at 60°C, and then the stainless steel tube is moved to 80°C. Use ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com