A kind of preparation method of metal telluride flower-like micro-nano structure

A technology of metal telluride and micro-nano structure, applied in the direction of binary selenium/tellurium compounds, etc., can solve the problems of difficult control of multi-dimensional morphology, complicated preparation process, and difficult preparation of multi-dimensional templates, so as to expand the application field of materials and simplify the process , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

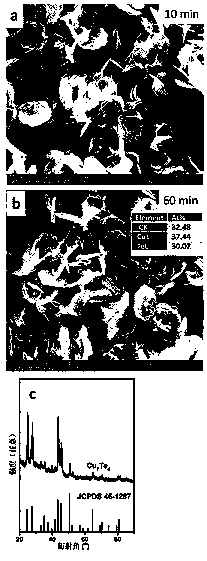

[0023] The preparation method of the metal telluride flower-like micro-nano structure in this example, the synthesis of Cu 7 Te 4 The flower-like micro-nano structure, the steps are as follows: take 0.05 mmol (0.1132 g) of sodium tellurite, 0.4 g of polyvinylpyrrolidone (molecular weight of 24000), 0.0932 g of sodium acetate, 4 mL of ethylenediamine, 0.2 g Zinc acetylacetonate and 20 mL of ethylene glycol were added to a 50 mL three-necked flask to form a mixed solution and heated to 50 o C for 40 minutes to exclude oxygen, then heated to 175 o C until the solution turns brown. Then add 0.229 g of copper acetylacetonate, react for half an hour, and use ethanol to centrifuge and purify more than twice to obtain Cu 7 Te 4 flower-like micro-nanostructures. (Scanning electron microscope and X-ray diffraction pictures are shown in figure 1 ).

Embodiment 2

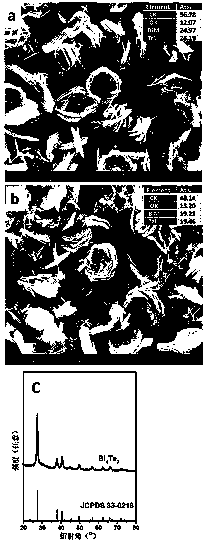

[0025] The preparation method of the metal telluride flower-like micro-nano structure in this example, the synthesis of Bi 4 Te 3 The flower-like micro-nano structure, the steps are as follows: take 0.05 mmol (0.1132 g) of sodium tellurite, 0.4 g of polyvinylpyrrolidone (molecular weight of 24000), 0.0932 g of sodium acetate, 4 mL of ethylenediamine, 0.2 g Zinc acetylacetonate and 20 mL of ethylene glycol were added to a 50 mL three-necked flask to form a mixed solution and heated to 50 o C for 40 minutes to exclude oxygen, then heated to 175 o C until the solution turns brown. Then quickly add 0.1053 g of bismuth chloride, react for half an hour, and use ethanol to centrifuge and purify more than twice to get Bi 4 Te 3 flower-like micro-nanostructures. (Scanning electron microscope and X-ray diffraction pictures are shown in figure 2 ).

Embodiment 3

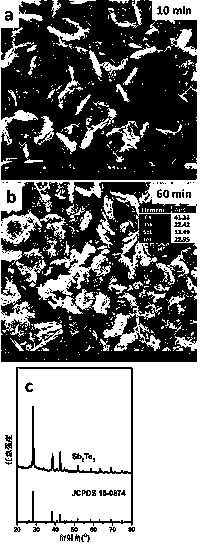

[0027] The preparation method of the metal telluride flower-like micro-nano structure in this example, the synthesis of Sb 2 Te 3 The steps are as follows: Take 0.05 mmol (0.1132 g) of sodium tellurite, 0.4 g of polyvinylpyrrolidone (molecular weight: 24000), 0.0932 g of sodium acetate, 4 mL of ethylenediamine, 0.2 g Zinc acetylacetonate and 20 mL of ethylene glycol were added to a ready-made mixed solution in a 50 mL three-neck flask and heated to 50 o C for 40 minutes to exclude oxygen, then heated to 175 o C until the solution turns brown. Then quickly add 0.1000 g of antimony acetate, react for half an hour, and use ethanol to centrifuge and purify more than twice to get Sb 2 Te 3 flower-like micro-nanostructures. (Scanning electron microscope and X-ray diffraction pictures are shown in image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com