Method for separating cynomorium songaricum polysaccharides through deep-eutectic solvent/salt two-aqueous-phase extraction

A technology of deep eutectic solvent and Cynomorium polysaccharide, which is applied in the field of deep eutectic solvent/salt two-phase extraction and separation of Cynomorium polysaccharide, which can solve the problems of low extraction rate of Cynomorium polysaccharide, cumbersome operation steps, and large consumption of reagents, etc. problems, achieve the effects of mild conditions, wide sources of raw materials, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

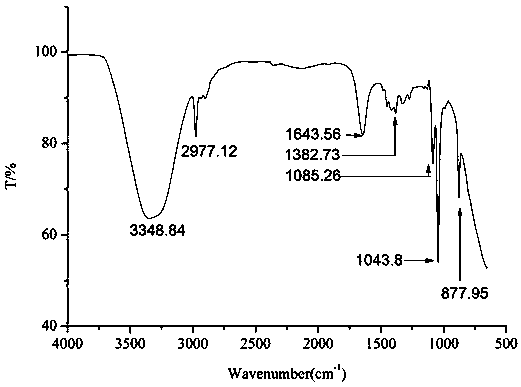

Image

Examples

Embodiment 1

[0027] A method for separating Cynomorium polysaccharide by deep eutectic solvent / salt two-phase extraction, the Cynomorium raw material used in the method is the Cynomorium powder produced in Gansu after degreasing and natural drying, and the method comprises the following steps:

[0028] Step 1. Preparation of Cynomorium polysaccharide crude extract: take 1 g of Cynomorium powder, add 20 mL of 40% choline chloride-malic acid deep eutectic solvent with a volume percentage of water content, mix well, and place in an ice bath at 4°C Ultrasonic treatment is carried out under the conditions, the ultrasonic treatment power is 300W, the pulse working mode is ultrasonic 2s, intermittent 2s, ultrasonic time is 30 minutes, then the solution is centrifuged at 4000 rpm for 5 minutes, and the supernatant is taken to obtain Cynomorium Polysaccharide crude extract;

[0029] Step 2, two-phase extraction: add 10 g of dipotassium hydrogen phosphate powder to the crude extract of Cynomorium po...

Embodiment 2

[0034] A method for separating Cynomorium polysaccharide by deep eutectic solvent / salt two-phase extraction, the Cynomorium raw material used in the method is the Cynomorium powder produced in Gansu after degreasing and natural drying, and the method comprises the following steps:

[0035] Step 1. Preparation of Cynomorium polysaccharide crude extract: take 1g Cynomorium powder, add 30mL of 50% choline chloride-glycerol deep eutectic solvent with a volume percentage of water content, mix well, under 4 ℃ ice bath condition Carry out ultrasonic treatment, the ultrasonic treatment power is 350W, the pulse working mode is ultrasonic for 2s, the interval is 2s, and the ultrasonic time is 40 minutes, then the solution is centrifuged at 3000 revolutions per minute for 10 minutes, and the supernatant is taken to obtain Cynomorium polysaccharide crude. extract;

[0036] Step 2, two-phase extraction: add 15g of solid dipotassium hydrogen phosphate powder to the crude extract of Cynomori...

Embodiment 3

[0041] A method for separating Cynomorium polysaccharide by deep eutectic solvent / salt two-phase extraction, the Cynomorium raw material used in the method is the Cynomorium powder produced in Gansu after degreasing and natural drying, and the method comprises the following steps:

[0042]Step 1. Preparation of Cynomorium polysaccharide crude extract: Take 1g Cynomorium powder, add 30mL of 45% choline chloride-succinic acid deep eutectic solvent with a volume percentage of water content, mix well, and place in an ice bath at 4°C. Ultrasonic treatment was carried out under the following conditions, the ultrasonic treatment power was 400W, the pulse working mode was ultrasonic 2s, the interval was 2s, and the ultrasonic time was 50 minutes, and then the solution was centrifuged at a speed of 3000 revolutions per minute for 10 minutes, and the supernatant was taken to obtain Cynomorium polysaccharide. crude extract;

[0043] Step 2, two-phase extraction: add 10g of solid dipotass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com