A double metal hydroxide ceramic membrane for desalination of seawater and its preparation method

A hydroxide and ceramic membrane technology, applied in chemical instruments and methods, seawater treatment, general water supply conservation, etc., can solve problems such as low filtration efficiency, difficult seawater industrial desalination, and low efficiency of seawater desalination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

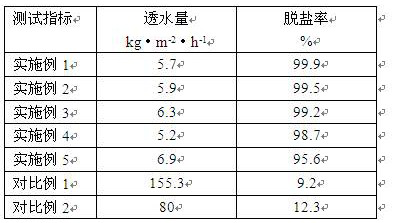

Examples

Embodiment 1

[0027] A double metal hydroxide ceramic membrane for seawater desalination, comprising a porous ceramic substrate and a film covered on the porous ceramic substrate, the film is made of the following parts by weight: reduced graphene oxide 8 parts by weight , 20 parts by weight of magnesium sulfate, 30 parts by weight of aluminum nitrate, 5 parts by weight of sorbitan fatty acid ester, 5 parts by weight of n-decyltrimethoxysilane, 3 parts by weight of propylene glycol butyl ether, N,N-dimethylformaldehyde 60 parts by weight of amide, and 125 parts by weight of water.

[0028] The preparation method of the layered double metal hydroxide ceramic membrane used for seawater desalination comprises the following steps:

[0029] (1) Preparation of reduced graphene oxide: Weigh 200 mg of graphene oxide and add it to 100 ml of deionized water, and ultrasonically strip it for 0.5 h to form a graphene oxide mixture; add 600 mg of EDDS to the graphene oxide mixture, and mix evenly by ultr...

Embodiment 2

[0034] A double metal hydroxide ceramic membrane for seawater desalination, comprising a porous ceramic substrate and a film covered on the porous ceramic substrate, the film is made of the following parts by weight: 10 parts by weight of reduced graphene oxide , 15 parts by weight of magnesium chloride, 40 parts by weight of aluminum chloride, 7 parts by weight of polyoxyethylene fatty acid ester, 3 parts by weight of n-decyltrimethoxysilane, 5 parts by weight of ethylene glycol butyl ether acetate, N,N-di 75 parts by weight of methyl formamide, and 120 parts by weight of water.

[0035] The preparation method of the layered double metal hydroxide ceramic membrane used for seawater desalination comprises the following steps:

[0036] (1) Preparation of reduced graphene oxide: Weigh 200 mg of graphene oxide and add it to 100 ml of deionized water, and ultrasonically strip it for 0.5 h to form a graphene oxide mixture; add 600 mg of EDDS to the graphene oxide mixture, and mix e...

Embodiment 3

[0041] A double metal hydroxide ceramic membrane for seawater desalination, comprising a porous ceramic substrate and a film covered on the porous ceramic substrate, the film is made of the following parts by weight: reduced graphene oxide 5 parts by weight , 25 parts by weight of magnesium chloride, 20 parts by weight of aluminum sulfate, 3 parts by weight of polyoxyethylene fatty amine, 6 parts by weight of n-decyltrichlorosilane, 1 part by weight of propylene glycol butyl ether, 50 parts by weight of N-methylpyrrolidone, 150 parts by weight of water share.

[0042] The preparation method of the layered double metal hydroxide ceramic membrane for seawater desalination is characterized in that it comprises the following steps:

[0043] (1) Preparation of reduced graphene oxide: Weigh 200 mg of graphene oxide and add it to 100 ml of deionized water, and ultrasonically strip it for 0.5 h to form a graphene oxide mixture; add 600 mg of EDDS to the graphene oxide mixture, and mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com