Phase-change microsphere as well as preparation method and application thereof

A technology of phase-change microspheres and microspheres, which is applied in the field of nanoporous materials and phase-change energy storage, can solve the problems of high specific surface area, inapplicability, high porosity, etc., and achieve simple preparation process, large enthalpy value, excellent The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Another aspect of the embodiments of the present invention provides a method for preparing the aforementioned phase-change microspheres. In a typical embodiment, the preparation method includes: using airgel microspheres as templates, filling them by melt impregnation, and filling the airgel microspheres The phase change material is introduced into the three-dimensional network of the spheres, and the external residual phase change material is removed, followed by cooling to obtain functional phase change microspheres.

[0047] As one of the preferred solutions, the preparation method includes: providing airgel microspheres as a template, and impregnating the airgel microspheres in a molten phase change material at 30-150°C under vacuum or normal pressure environment , standing for 0.5 to 12 hours, melt-filled, cooled and solidified to obtain phase-change microspheres.

[0048] Further, the preparation method further includes: placing the phase-change microspheres on fi...

Embodiment 1

[0070] (1) Selecting graphene airgel microspheres with a diameter of 300 μm as a template for preparing phase change microspheres;

[0071] (2) Put the graphene airgel microspheres and solid paraffin together in a vacuum at 80° C. for 3 hours.

[0072] (3) The microspheres impregnated with the phase change material were taken out, placed on filter paper, and left to stand at 80° C. for 1 hour to remove excess phase change material on the outer surface of the microspheres.

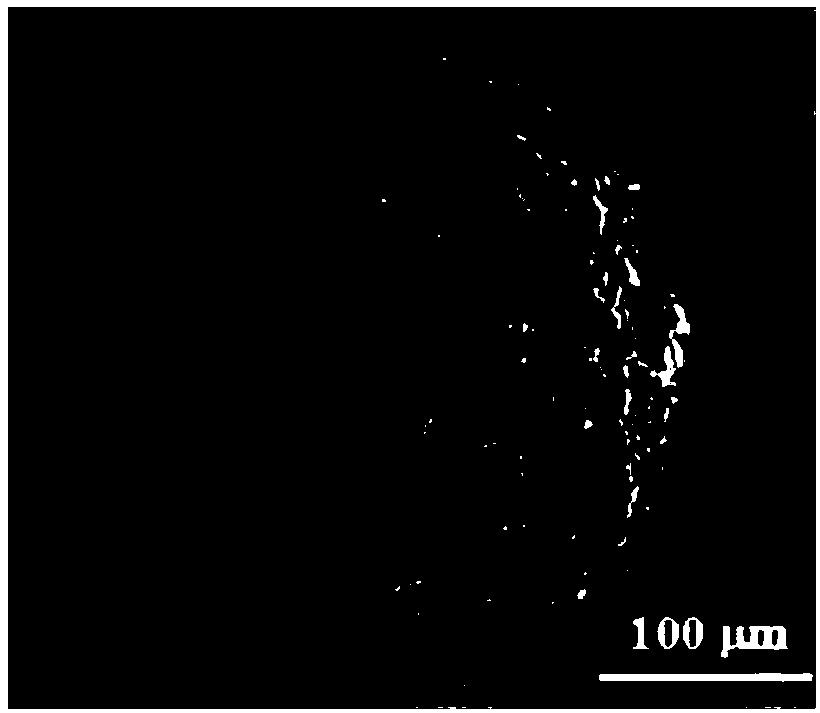

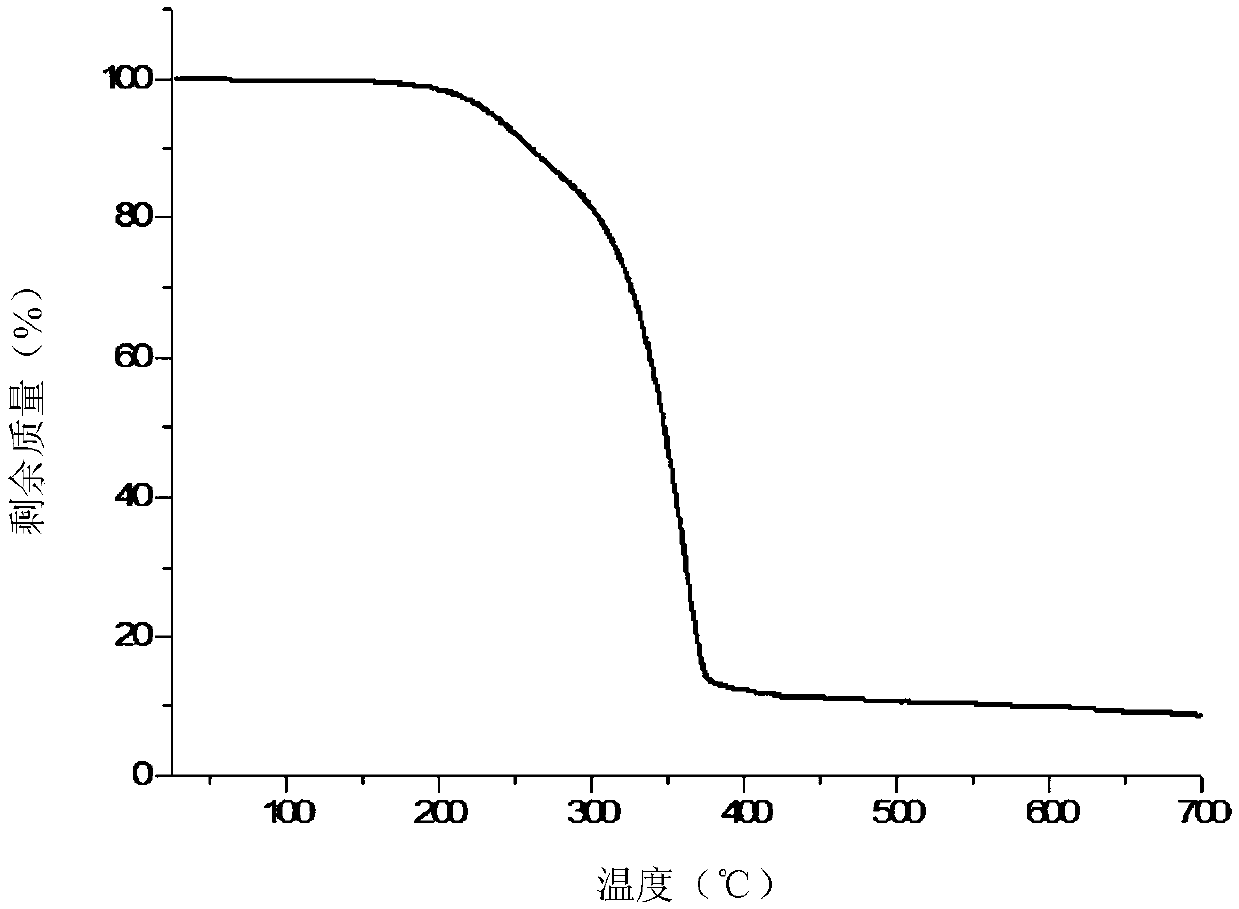

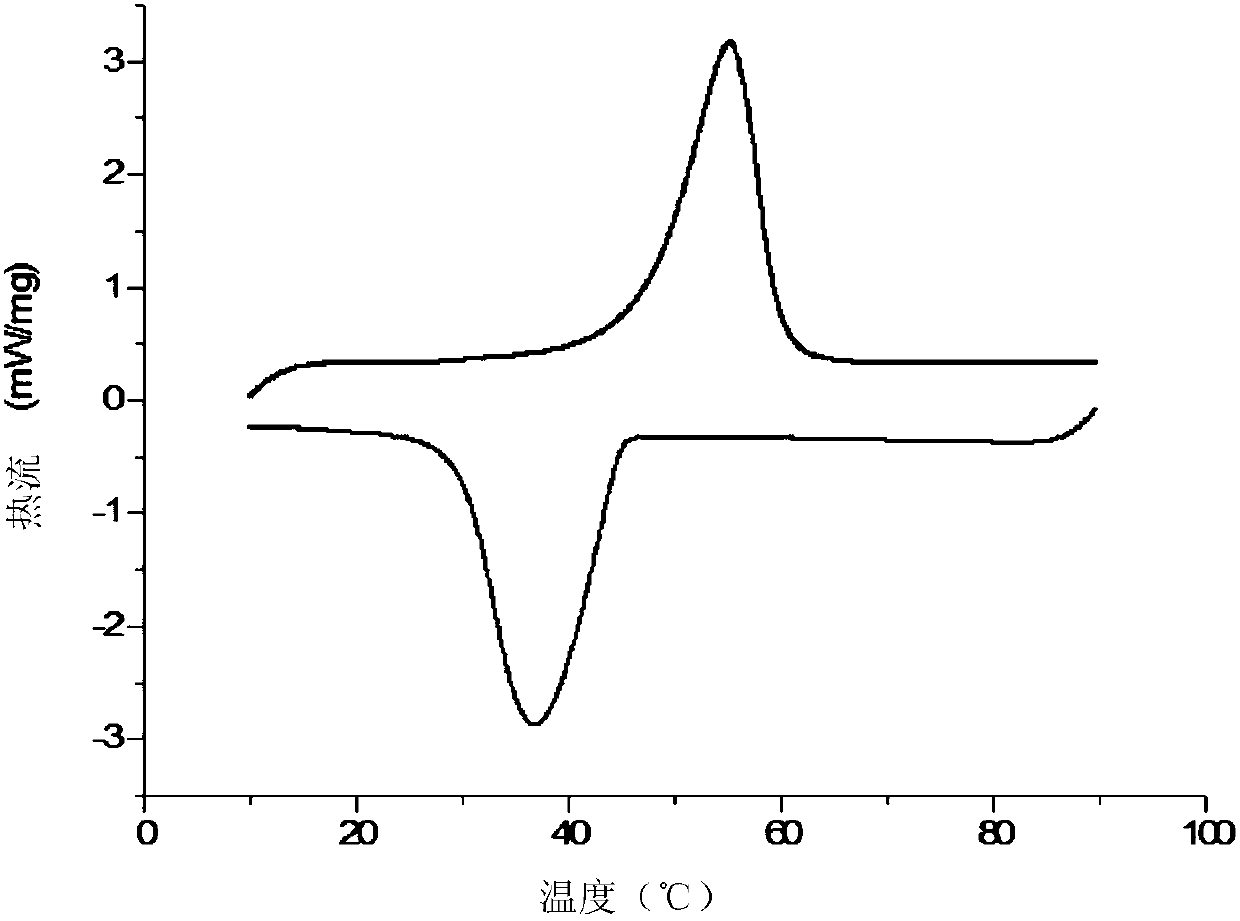

[0073] (4) cooling the above microspheres at room temperature to obtain the phase change microspheres. figure 1 The SEM photo of the phase change microspheres obtained by the present embodiment is shown, figure 2 The TG curve of the phase change microspheres obtained by the present embodiment is shown, image 3 The DSC curve of the phase change microspheres obtained in this example is shown.

[0074] (5) Heat flow stabilizer: apply a voltage across the phase change microspheres, Figure 4 A schematic d...

Embodiment 2

[0076] (1) Select PI-based carbon airgel microspheres with a diameter of 400 μm as templates for preparing phase-change microspheres;

[0077] (2) Put the PI-based carbon airgel microspheres and solid paraffin together in a vacuum at 70° C. for 5 hours.

[0078] (3) The microspheres impregnated with the phase change material were taken out, placed on filter paper, and allowed to stand at 70° C. for 1 hour to remove excess phase change material on the outer surface of the microspheres.

[0079] (4) cooling the above microspheres at room temperature to obtain the phase change microspheres.

[0080] (5) Heat flow stabilizer: apply an alternating current with a pulse width of 1 ms at both ends of the phase change microsphere, Figure 6 The current signal of the phase-change microspheres in the present embodiment is shown, Figure 7 The voltage change of the phase change microspheres in this embodiment is shown, and please refer to Table 1 for other parameters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com