Efficient wastewater decolorizing agent and method for preparing same

A decolorizing agent and wastewater technology, which is applied in textile industry wastewater treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of small floc particles, slow sedimentation speed, low molecular weight, etc., and achieve fast flocculation speed and easy metering and addition , The effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

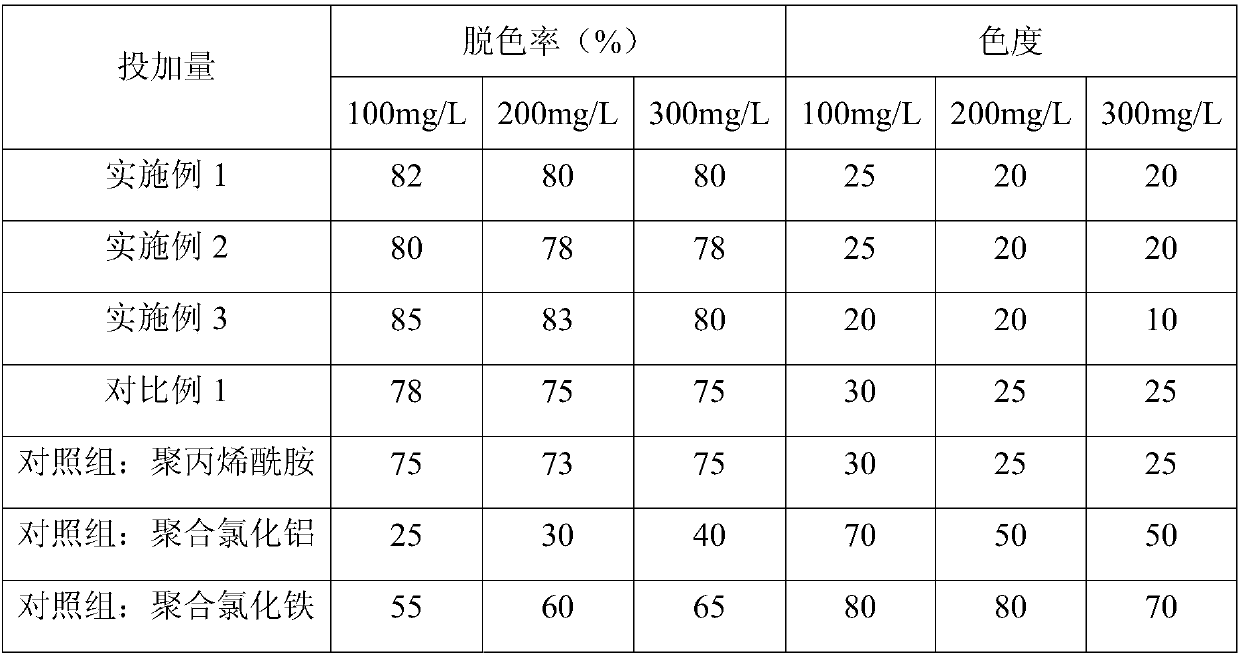

Examples

Embodiment 1

[0020] Dicyandiamide, formaldehyde, ammonium chloride and ethylenediamine are prepared decolorizing agent according to the amount ratio of following substances, dicyandiamide: formaldehyde: ammonium chloride: ethylenediamine=1:5:0.5:0.2, formaldehyde and Ammonium chloride is added to the reactor twice, 60% is added for the first time, 40% is added for the second time, and dicyandiamide and ethylenediamine are added at one time. First, add dicyandiamine, ethylenediamine and 60% formaldehyde and ammonium chloride into the reactor, heat it in a water bath to 30°C, and there will be exothermic phenomenon when the reaction starts, stop heating at this time, and continue stirring for 30 minutes , add the remaining 40% formaldehyde and ammonium chloride, control the temperature to rise slowly, and react at 70°C for 3 hours to prepare the ethylenediamine-modified dicyandiamide formal decolorizer.

Embodiment 2

[0022] Dicyandiamide, formaldehyde, ammonium chloride and ethylenediamine are prepared decolorizing agent according to the amount ratio of following substances, dicyandiamide: formaldehyde: ammonium chloride: ethylenediamine=1:2:0.5:0.05, formaldehyde and Ammonium chloride is added to the reactor in three times, 40% for the first time, 30% for the second time, 30% for the third time, and dicyandiamine and ethylenediamine are added at one time. First, add dicyandiamine, ethylenediamine and 40% formaldehyde and ammonium chloride into the reactor, heat it in a water bath to 50°C, and there will be exothermic phenomenon when the reaction starts, stop heating at this time, and continue stirring for 90 minutes , then add 30% formaldehyde and ammonium chloride, and when the temperature rise rate of the reaction mixture is less than 5°C / min, add the remaining 30% formaldehyde and ammonium chloride, control the temperature to rise slowly, and react at 90°C for 6 hours to prepare Get de...

Embodiment 3

[0024] Dicyandiamide, formaldehyde, ammonium chloride and ethylenediamine are prepared decolorizing agent according to the amount ratio of following substances, dicyandiamide: formaldehyde: ammonium chloride: ethylenediamine=1:2:1:0.1, formaldehyde and Ammonium chloride is added to the reactor twice, 60% is added for the first time, 40% is added for the second time, and dicyandiamide and ethylenediamine are added at one time. First, add dicyandiamine, ethylenediamine and 60% formaldehyde and ammonium chloride into the reactor, heat it in a water bath to 40°C, and there will be exothermic phenomenon when the reaction starts, stop heating at this time, and continue stirring for 60 minutes , add the remaining 40% formaldehyde and ammonium chloride, control the temperature to rise slowly, and react at 85°C for 4 hours to prepare the decolorizing agent ethylenediamine-modified dicyandiamide formal (DCD-HCHO).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com