Edible rapeseed protein composite film

A technology of rapeseed protein and composite film, which is applied in the field of food packaging and can solve problems such as preparing edible packaging films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Preparation of rapeseed protein hydrolyzate

[0018] The preparation of rapeseed protein hydrolyzate comprises the following steps:

[0019] (1) Obtain rapeseed meal. Dry the rapeseed in an oven at 35-40°C for 24 hours at a constant temperature, use a sheller to dehull the rapeseed, and use a blower to screen out the rapeseed husk. The husked rapeseed is crushed to a particle size of 100-800 μm using a high-speed universal grinder to obtain rapeseed meal.

[0020] (2) Degreasing of rapeseed meal. Degreasing the rapeseed meal by Soxhlet extraction method for 6-8 hours, and then crushing to a particle size of 100-600 μm to obtain the defatted rapeseed meal. The defatted rapeseed meal was packed in a sealed bag and refrigerated at 4°C for later use.

[0021] (3) Rapeseed protein was extracted from defatted rapeseed meal by alkali dissolution and acid precipitation. Weigh defatted rapeseed meal, dissolve it in deionized water (the mass ratio of defatted rapes...

Embodiment 2

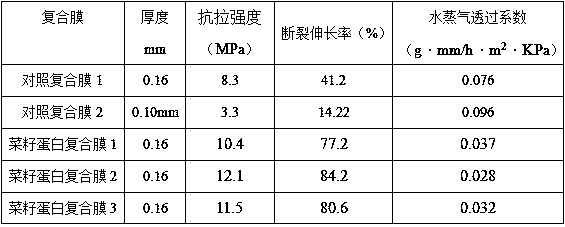

[0028] Embodiment two prepares edible rapeseed protein composite film

[0029] Take the rapeseed protein hydrolyzate with a degree of hydrolysis of 10%, and use water as a solvent to prepare a 40 g / L rapeseed protein hydrolyzate solution. With the acetic acid aqueous solution of 20g / L as solvent, the chitosan solution of preparation 40g / L, as solution B. The rapeseed protein hydrolyzate solution and solution B were fully stirred with a magnetic stirrer respectively, and then mixed in equal volumes to obtain solution A. Add 8 g of glycerin to each liter of solution A, and fully stir with a magnetic stirrer (rotating speed: 500 r / min) at 60° C. for 2 hours to obtain a film-forming solution. Pour the film-forming solution into the groove (10cm×10cm×1mm) of the polytetrafluoropropylene mold to form it, dry it in a constant humidity and constant temperature drying oven at 27°C and a relative humidity of 50%-55% for 24 hours, and peel off the film to obtain Rapeseed protein compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com