Pretreatment technology for detecting metal impurity in puerarin active ingredient

A technology for metal impurities and raw materials, applied in the field of analytical chemistry, can solve the problems of unreported application and low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

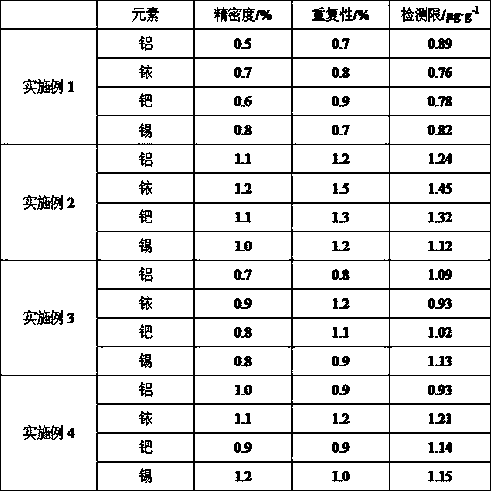

Examples

Embodiment 1

[0019] Example 1: A pretreatment process for detecting metal impurities in puerarin bulk drug

[0020] (1) Take kudzu root, crush it into powder, pass through a 50-mesh sieve, and then immerse it in 0.05mol / L hydrochloric acid solution for 1 hour.

[0021] (2) Add 0.05 mol / L sodium hydroxide solution to the system in step (1), adjust the pH value to neutral, and then filter to remove the filtrate to obtain a filter residue.

[0022] (3) Use hydrogen peroxide with a mass fraction of 0.1% to treat the filter residue collected in step (2), wash it twice, filter the filter residue, and then dry the filter residue at 55°C.

[0023] (4) Take the filter residue after drying in step (3), add EDTA solution and sodium hydroxide solution to it, and stir and react at 25° C. for 1 hour.

[0024] (5) Take the supernatant after the reaction in step (4), and use high performance liquid chromatography to detect the content of metal ions therein.

Embodiment 2

[0025] Example 2: A pretreatment process for detecting metal impurities in puerarin bulk drug

[0026] A kind of technique that is used to detect metal impurity in puerarin crude drug, described technique comprises the following steps:

[0027] (1) Take kudzu root, crush it into powder, pass through a 70-mesh sieve, and then immerse it in 0.08mol / L hydrochloric acid solution for 2 hours.

[0028] (2) Add 0.08 mol / L sodium hydroxide solution to the system in step (1), adjust the pH value to neutral, and then filter to remove the filtrate to obtain a filter residue.

[0029] (3) Treat the filter residue collected in step (2) with 0.2% hydrogen peroxide, wash it three times, filter the filter residue, and then dry the filter residue at 60°C.

[0030] (4) Take the filter residue after drying in step (3), add EDTA solution and sodium hydroxide solution to it, and stir and react at 30° C. for 2 hours.

[0031] (5) Take the supernatant after the reaction in step (4), and use high p...

Embodiment 3

[0032] Example 3: A pretreatment process for detecting metal impurities in puerarin bulk drug

[0033] A kind of technique that is used to detect metal impurity in puerarin crude drug, described technique comprises the following steps:

[0034] (1) Take kudzu root, crush it into powder, pass through an 80-mesh sieve, and then immerse it in 0.09mol / L hydrochloric acid solution for 2 hours.

[0035] (2) Add 0.09 mol / L sodium hydroxide solution to the system in step (1), adjust the pH value to neutral, and then filter to remove the filtrate to obtain a filter residue.

[0036] (3) Treat the filter residue collected in step (2) with 0.2% hydrogen peroxide, wash it three times, filter the filter residue, and then dry the filter residue at 58°C.

[0037] (4) Take the dried filter residue in step (3), add EDTA solution and sodium hydroxide solution to it, and stir and react at 30°C for 2 hours;

[0038] (5) Take the supernatant after the reaction in step (4), and use high performan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com