Radix stemonae polysaccharide, blended and modified chitosan membrane and application in preparation of anti-adhesion membrane material

A technology of blending modified chitosan film, applied in anti-adhesion film materials, blended modified chitosan film and its application in the preparation of anti-adhesion film materials, the field of polysaccharides, can solve the anti-adhesion effect Unsatisfactory, causing inflammatory reactions, unable to reduce adhesions and other problems, to achieve the effect of inhibiting adhesions, appropriate degradation speed, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

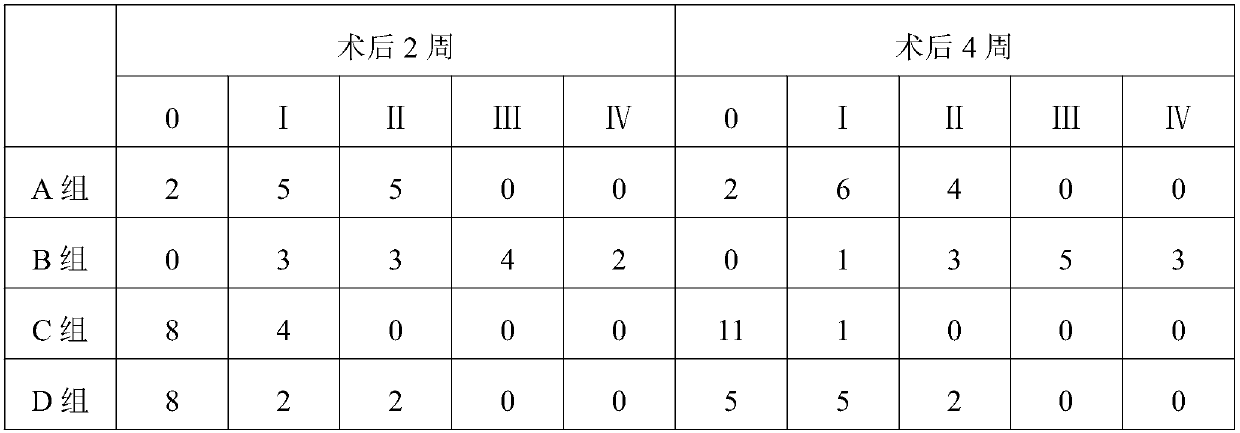

[0021] Preparation of Example 1 Blending Modified Chitosan Film and Evaluation of Anti-blocking Effect

[0022] One, the preparation of polysaccharide

[0023] The medicinal material of Phyllostachys chinensis is dried at a constant temperature of 50°C, crushed and passed through a 60-mesh sieve. Weigh 100g of medicinal material powder, extract with boiling water reflux 3 times at a material-to-liquid ratio (m / V) of 1:30, each time for 2 hours, collect the extract, centrifugally filter, concentrate the filtrate to 100ml, add 400ml of absolute ethanol for alcohol precipitation After standing overnight, filter, the precipitate is deproteinized by Sevage method and redissolved, and then precipitated with 75% ethanol, and the precipitate is repeatedly washed with absolute ethanol and acetone to obtain the polysaccharides of the leaves, and the obtained polysaccharides are dialyzed with a dialysis bag The cut-off, dialysis bag adopts American spectrum medical spectrumlabs product,...

Embodiment 2

[0040] The preparation of embodiment 2 blending modified chitosan film

[0041] One, the preparation of polysaccharide

[0042] Liliba medicinal materials were dried at a constant temperature of 50°C, crushed and passed through a 60-mesh sieve. Weigh 100g of medicinal material powder, extract with boiling water reflux 3 times at a material-to-liquid ratio (m / V) of 1:30, each time for 2 hours, collect the extract, centrifugally filter, concentrate the filtrate to 100ml, add 400ml of absolute ethanol for alcohol precipitation After standing overnight, filter, the precipitate is deproteinized by Sevage method and redissolved, and then precipitated with 75% ethanol, and the precipitate is repeatedly washed with absolute ethanol and acetone to obtain the polysaccharides of the leaves, and the obtained polysaccharides are dialyzed with a dialysis bag The cut-off and dialysis bags are made by American Spectrum Medical Spectrumlabs. Dialysis bags with a molecular weight cut-off of 15...

Embodiment 3

[0045] The preparation of embodiment 3 blending modified chitosan film

[0046] One, the preparation of polysaccharide

[0047] The medicinal material of vines is dried at a constant temperature of 50°C, crushed and passed through a 60-mesh sieve. Weigh 100g of medicinal material powder, extract with boiling water reflux 3 times at a material-to-liquid ratio (m / V) of 1:30, each time for 2 hours, collect the extract, centrifugally filter, concentrate the filtrate to 100ml, add 400ml of absolute ethanol for alcohol precipitation After standing overnight, filter, the precipitate is deproteinized by Sevage method and redissolved, and then precipitated with 75% ethanol, and the precipitate is repeatedly washed with absolute ethanol and acetone to obtain the polysaccharides of the leaves, and the obtained polysaccharides are dialyzed with a dialysis bag The cut-off and dialysis bags are made by American Spectrum Medical Spectrumlabs. Dialysis bags with a molecular weight cut-off of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap