Vehicle low-odor antistatic ABS composite material and preparation method thereof

A composite material and low-odor technology, which is applied in the field of low-odor antistatic ABS composite materials for automobiles and its preparation, can solve the problems of unsatisfactory odor absorption efficiency, unsatisfactory odor and antistatic properties of automobile manufacturers, and achieves good mechanical properties, Low production cost and improved odor level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the examples.

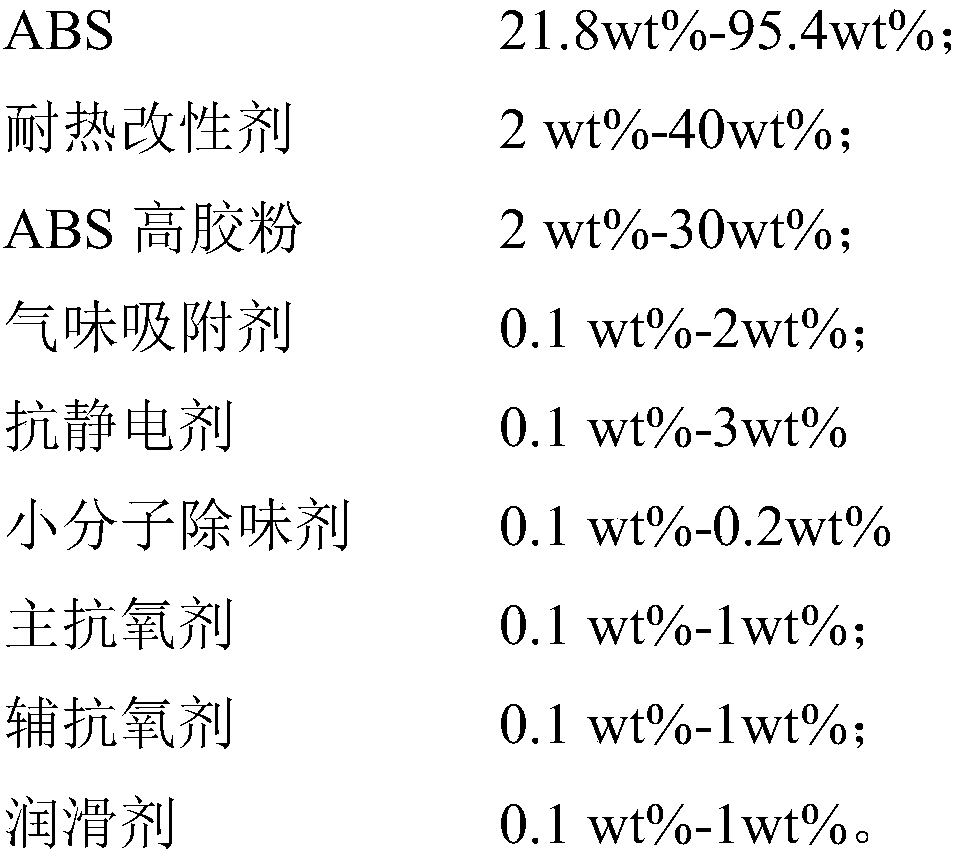

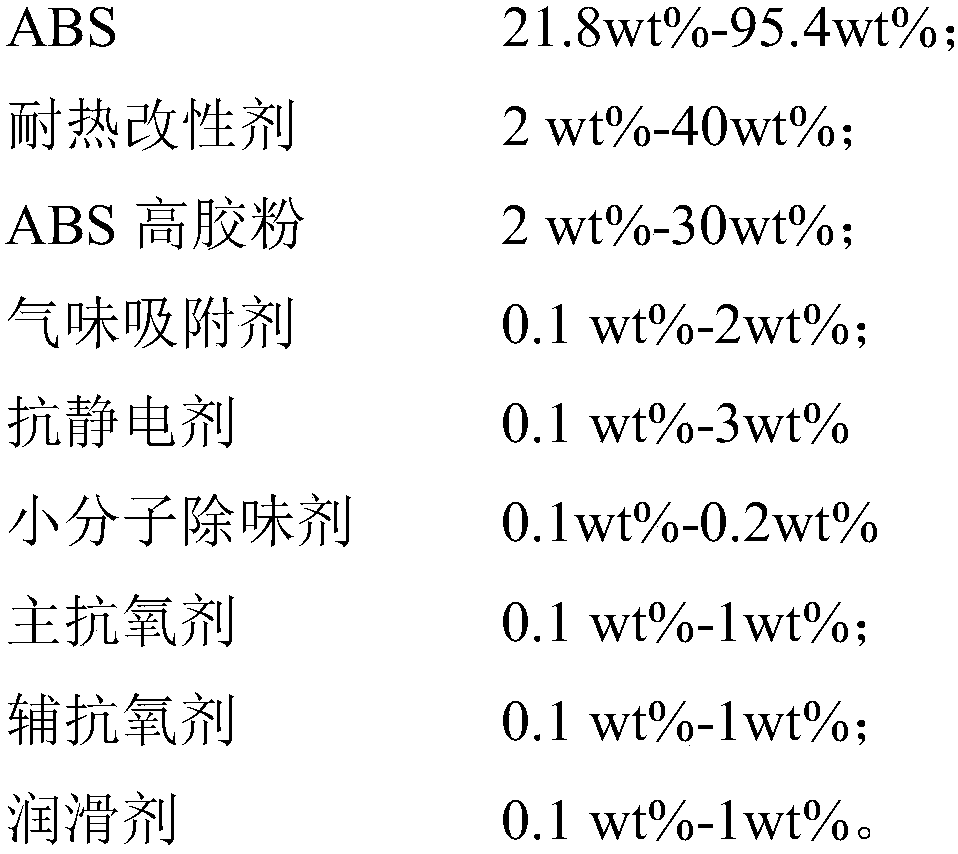

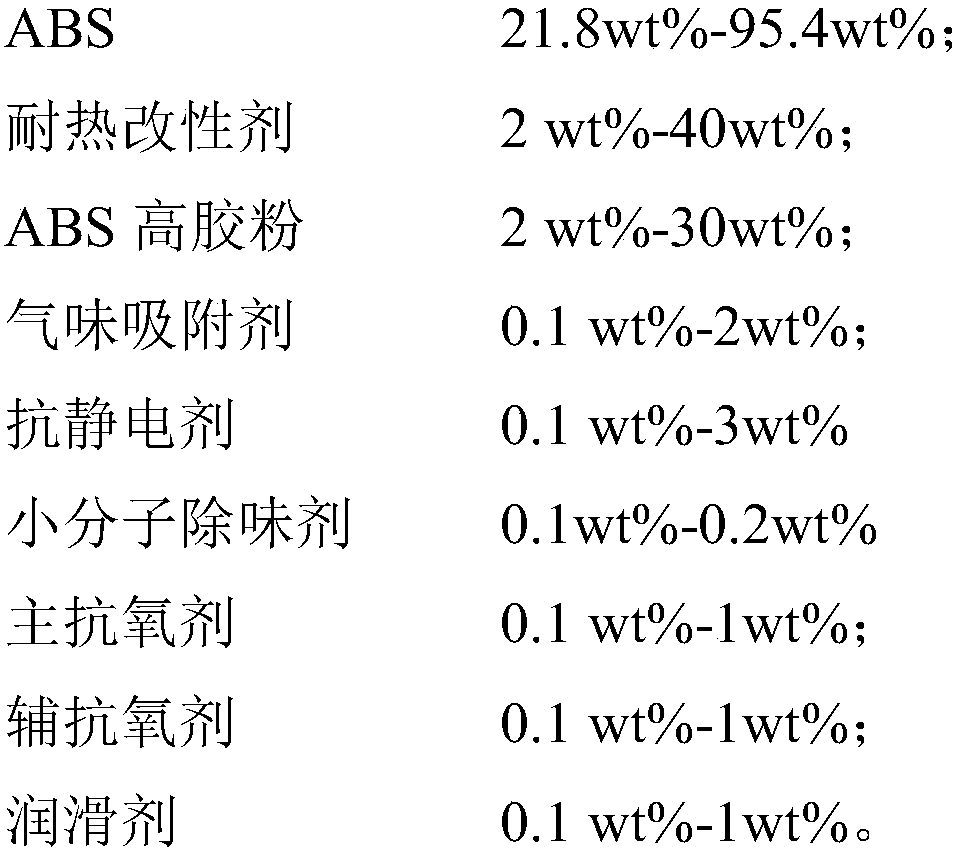

[0031] The components of the present invention are composed of ABS, heat-resistant modifier, ABS high rubber powder, odor adsorbent, antistatic agent, small molecule deodorant, main antioxidant, auxiliary antioxidant, lubricant, and its formulation is as follows: Down:

[0032]

[0033] in,

[0034] The ABS is ABS 8434 produced by Shanghai Gaoqiao Petrochemical Company;

[0035] The heat-resistant modifier is MS-NIP from Nippon Denki;

[0036] ABS high rubber powder is HR181 produced by Kumho, Korea;

[0037] Powdered molecular sieves are used as the odor adsorbent;

[0038] Antistatic agent selects monoglyceride stearate for use;

[0039] The small molecule deodorant is distilled water;

[0040] The main antioxidant is Irganox 1010 produced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com