Rare earth metal ferroalloy wave-absorbing agent, preparation method and application thereof

A technology of rare earth metals and rare earth metal salts, used in radiation-absorbing coatings, coatings, anti-corrosion coatings, etc., can solve the problems of low stability and easy oxidation of absorbing materials, and achieve the best effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

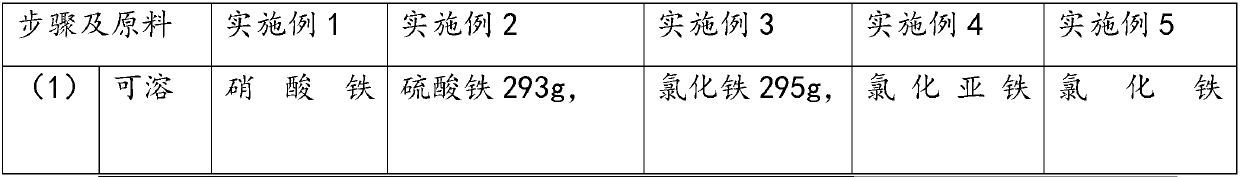

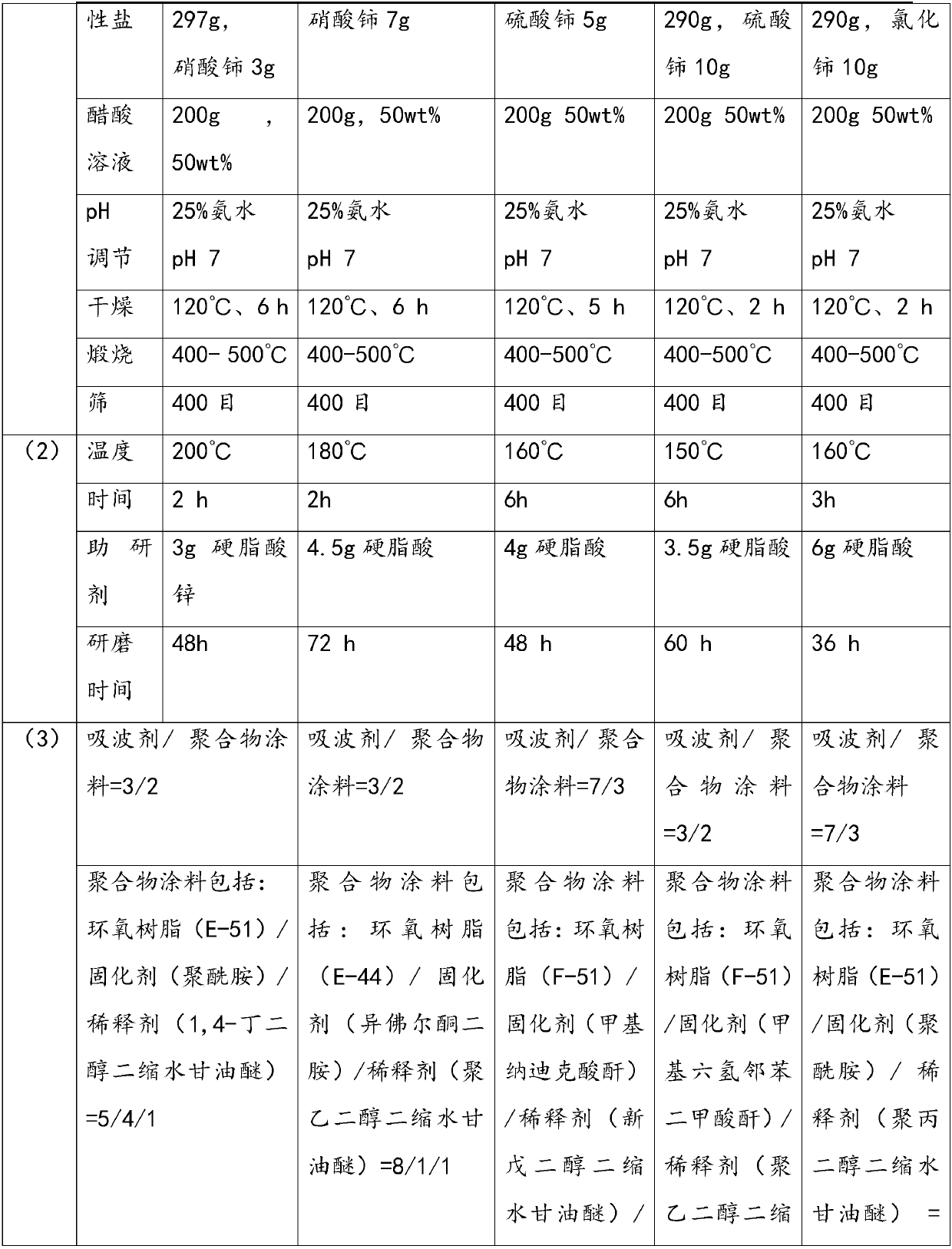

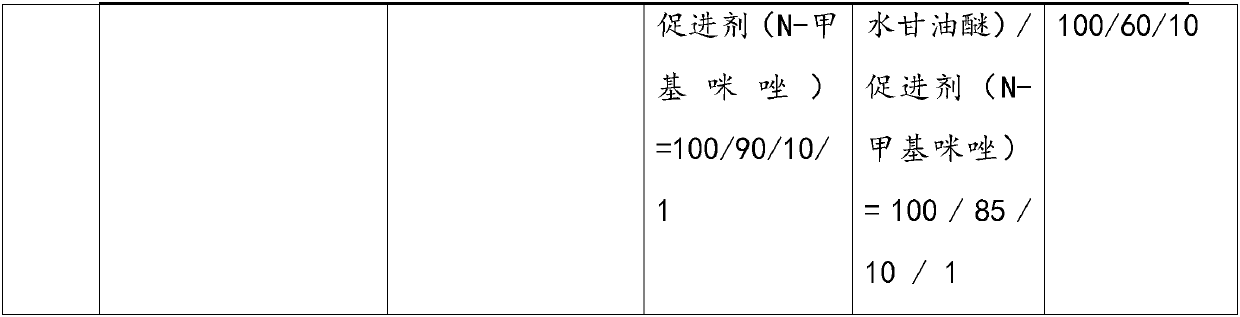

Examples

Embodiment 1

[0034] This embodiment provides a ferrocerium alloy wave absorbing agent and its preparation and application, specifically as follows:

[0035] (1) Accurately weigh 297g of ferric nitrate (relative molecular weight relative molecular mass is 241.88, the quality of iron is 68.8g), 3g of cerium nitrate (relative molecular weight is 434.12, the quality of cerium is 0.97g) in the container, dissolve in deionized water Make a mixed solution; add 200g, 50wt% acetic acid solution and stir evenly to obtain a uniform and stable solution;

[0036] Add dropwise ammonia water of 25% concentration to the solution, adjust the pH value to 7, so that a precipitate is produced until the amount of ammonia water is slightly excessive, filter and collect the precipitate, place the collected precipitate in a constant temperature drying oven at 120°C for 6 hours, and then Calcined at 400-500°C, cooled and ground to collect the 400-mesh sieve to obtain iron cerium oxide powder;

[0037](2) Place th...

Embodiment 2

[0041] This embodiment provides a ferrocerium alloy wave absorbing agent and its preparation and application, specifically as follows:

[0042] (1) Accurately weigh 293g of ferric sulfate (the relative molecular weight is 399.86, and the quality of iron is 82.07g), 7g of cerium nitrate (the relative molecular weight is 434.12, and the quality of cerium is 2.26g), and dissolve them in deionized water to form a mixed solution. Add 200g50wt% acetic acid solution and stir evenly to obtain a uniform and stable solution;

[0043] Add dropwise ammonia water of 25% concentration to the solution, adjust the pH value to 7, so that a precipitate is produced until the amount of ammonia water is slightly excessive, filter and collect the precipitate, place the collected precipitate in a constant temperature drying oven at 120°C for 6 hours, and then Calcined at 400-500°C, cooled and ground to collect the 400-mesh sieve to obtain iron cerium oxide powder;

[0044] (2) Place the iron-cerium...

Embodiment 3

[0048] This embodiment provides a ferrocerium alloy wave absorbing agent and its preparation and application, specifically as follows:

[0049] (1) Accurately weigh 295g of ferric chloride (the relative molecular weight is 162.204, and the quality of iron is 101.85g), 5g of cerium sulfate (the relative molecular weight is 404.30, and the quality of cerium is 3.47g), dissolve in deionized water and form a mixed solution. Add 200g of 50wt% acetic acid solution and stir evenly to obtain a uniform and stable solution; add dropwise ammonia water of 25% concentration to the solution, adjust the pH value to 7, and produce a precipitate until the ammonia water is slightly excessive, filter and collect the precipitate, and collect the The precipitate was dried in a constant temperature drying oven at 120°C for 5 hours, then calcined at 400-500°C, cooled and ground to collect the 400-mesh sieve to obtain iron cerium oxide powder;

[0050] (2) Place the iron-cerium oxide powder in a hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com