Environment-friendly coating based on cerium ion in-situ supported montmorillonite filler and preparation method of coating

A technology of environmentally friendly coatings and montmorillonite, applied in the field of coatings, can solve problems such as insufficient environmental protection, and achieve the effects of improving corrosion resistance, improving corrosion resistance, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

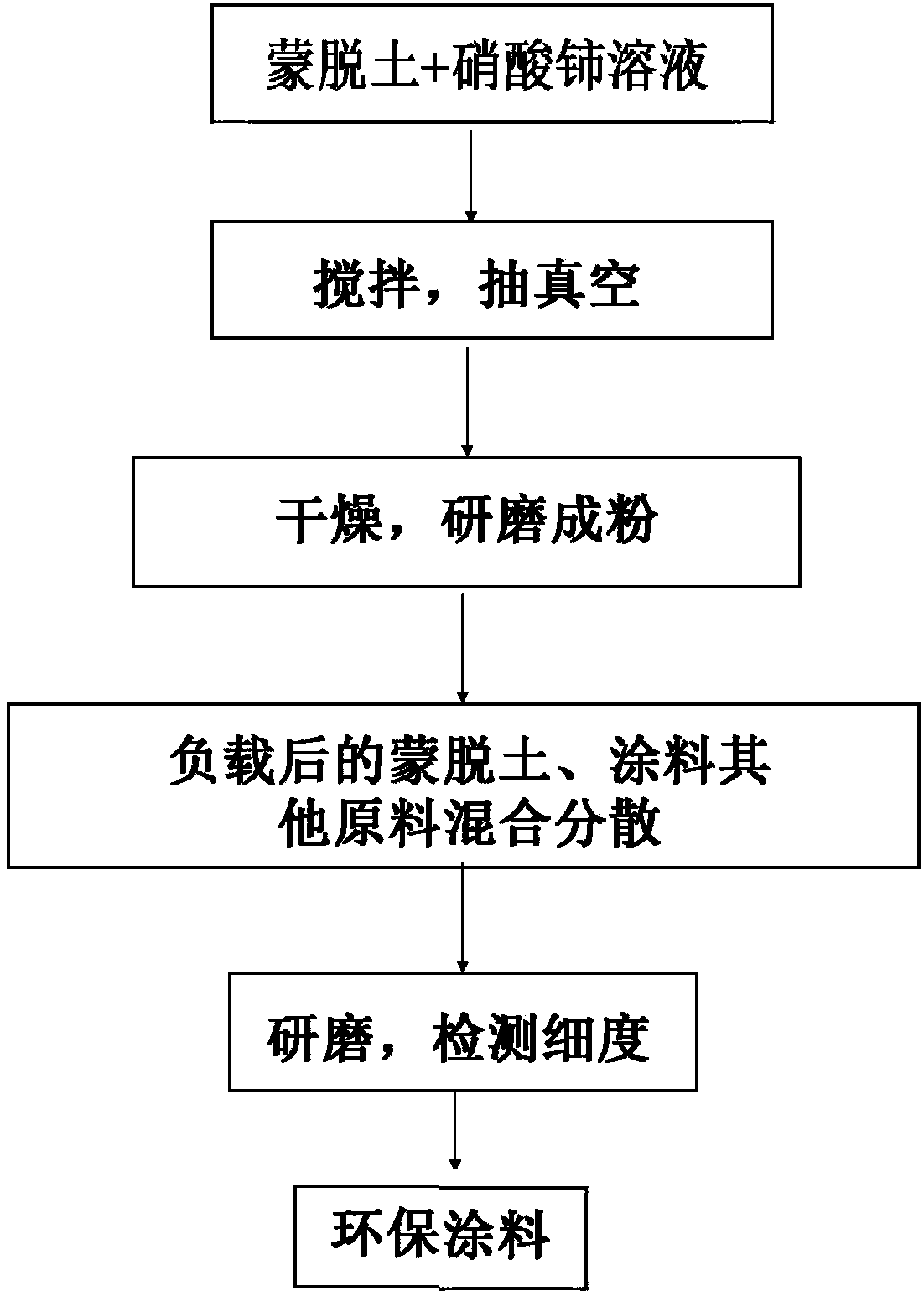

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a kind of environment-friendly coating based on cerium ion in situ loading montmorillonite filler, which includes equal amounts of the first component and the second component;

[0030] In terms of mass percentage, the first component includes the following components: 30% of epoxy resin, 5% of cerium ion in-situ loaded montmorillonite filler, 10% of titanium dioxide, 15% of modified zinc phosphate, 20% of toluene, wetting and dispersing Agent 3.5% and heavy calcium carbonate 16.5%; The cerium ion in-situ loaded montmorillonite filler is prepared by the following method: put montmorillonite in Ce(NO 3 ) 3 ·6H 2 In an aqueous solution of O, stir for 2 hours, then vacuumize, dry the obtained precipitated montmorillonite at 40-50°C, and grind it to a micron level; 3 ) 3 ·6H 2 The mass concentration in the O aqueous solution is 50g / L, the Ce(NO 3 ) 3 ·6H 2 Ce(NO 3 ) 3 ·6H 2 The mass concentration of O is 4.34g / L;

[0031] The second compo...

Embodiment 2

[0038] This embodiment provides a kind of environment-friendly coating based on cerium ion in situ loading montmorillonite filler, which includes equal amounts of the first component and the second component;

[0039] In terms of mass percentage, the first component includes the following components: 20% epoxy resin, 10% cerium ion in-situ loaded montmorillonite filler, 20% zinc oxide, 20% modified zinc phosphate, 10% methyl ethyl ketone, anti-settling agent 0.5% and kaolin 19.5%; the cerium ion in-situ loading montmorillonite filler is prepared by the following method: put montmorillonite into Ce(NO 3 ) 3 ·6H 2 In the aqueous solution of O, stir for 2.5h, then vacuumize, dry the obtained precipitated montmorillonite at 40°C, grind it to submicron level, and obtain it; wherein, the montmorillonite is in Ce(NO 3 ) 3 ·6H2 The mass concentration in the O aqueous solution is 48g / L, the Ce(NO 3 ) 3 ·6H 2 Ce(NO 3 ) 3 ·6H 2 The mass concentration of O is 4.5g / L;

[0040] Th...

Embodiment 3

[0047] This embodiment provides a kind of environment-friendly coating based on cerium ion in situ loading montmorillonite filler, which includes equal amounts of the first component and the second component;

[0048] In terms of mass percentage, the first component includes the following components: 50% of epoxy resin, 2% of cerium ion in-situ loaded montmorillonite filler, 2% of carbon black, 10% of modified zinc phosphate, 28% of isopropanol, Leveling agent 3% and barium sulfate 5%; This cerium ion in-situ loading montmorillonite filler is prepared by the following method: put montmorillonite into Ce(NO 3 ) 3 ·6H 2 In the aqueous solution of O, stir for 2 hours, then vacuumize, dry the obtained precipitated montmorillonite at 50°C, grind to micron level, and obtain; wherein, the montmorillonite is in Ce(NO 3 ) 3 ·6H 2 The mass concentration in the O aqueous solution is 52g / L, the Ce(NO 3 ) 3 ·6H 2 Ce(NO 3 ) 3 ·6H 2 The mass concentration of O is 4g / L;

[0049] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com