Method for preparing targeted mushroom cultivation bag material

A cultivation bag and targeted technology are applied in the field of preparation of mushroom cultivation bag materials, which can solve the problems of inability to meet the specific needs of edible mushroom growth, restrict the development of edible fungi, etc., and achieve sufficient raw material sources, good commercial properties, and fruiting body development. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present embodiment provides a kind of preparation method of highly targeted mushroom cultivation bag material, comprising the following steps:

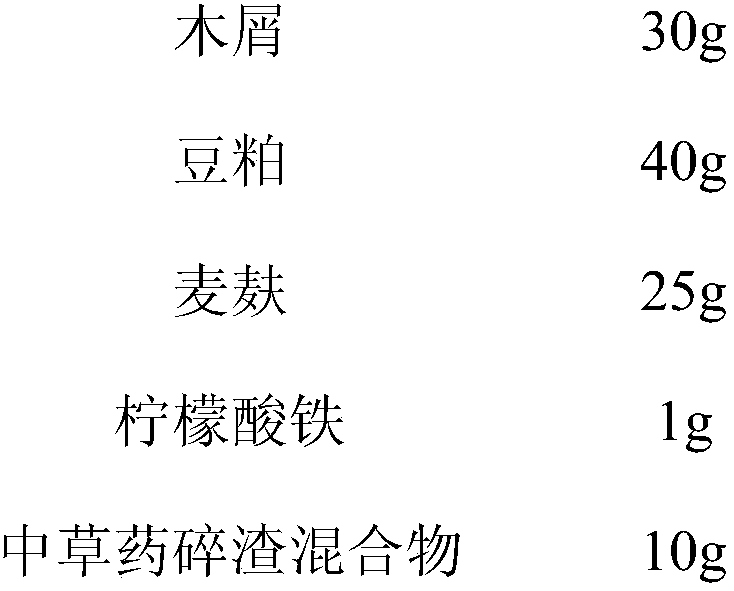

[0024] (1) Prepare cultivation materials by weight: including sawdust, soybean meal, wheat bran, ferric citrate, sufficient purified water; slag mixture.

[0025] Its components are as follows:

[0026]

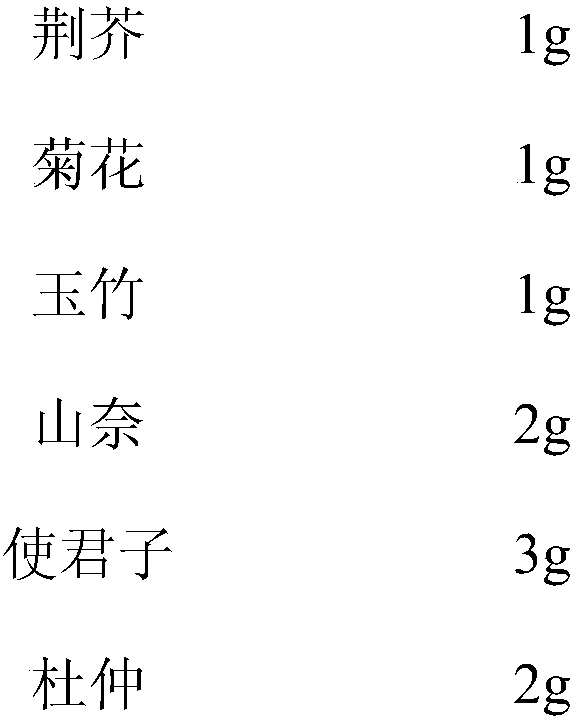

[0027] Among them, in the mixture of Chinese herbal medicine slag, the components of each Chinese medicine are as follows:

[0028]

[0029] (2) Prepare cultivation materials: pre-wet and soften soybean meal and wheat bran with water for 36 hours, then add sawdust and Chinese herbal medicine residue mixture and stir evenly;

[0030] (3) Fermented cultivation material: control the water content of the mixed material at 50-60%, spread it in the fermentation room, and ferment and heat up to 40-50°C;

[0031] (4) Cultivation material bagging: After the ammonia gas produced in the fermentation is dissipated, put the cu...

Embodiment 2

[0034] This example verifies the difference between the cultivation bag material provided in Example 1 and the traditional cultivation material, and the mushrooms cultivated.

[0035] Simultaneously inoculate the mushroom bacterial classification in the cultivation bag material that traditional cultivation waits for material and embodiment 1 provides, and it provides identical growth environment, after 15 days, compare the difference that grows mushroom, as shown in the table below:

[0036] Table 1 Growth of mushrooms

[0037] group

[0038] As can be seen from Table 1, the growth level and commercial value of mushrooms can be significantly improved by using the cultivation bag material provided in Example 1.

Embodiment 3

[0040] This example verifies whether the cultivation bag material provided in Example 1 has an effect on the growth of different fungi.

[0041] Select mushrooms, straw mushrooms, white fungus, Hericium erinaceus, Gastrodia elata, golden ear, and russula, and inoculate them in the cultivation bag materials provided in Example 1 respectively, and provide the optimal growth environment for them respectively according to the habits of fungi. After 15 days, , to evaluate the growth of each fungus.

[0042] evaluation standard:

[0043] Excellent: mycelium grows vigorously, the bacteria are strong, the cap is large and thick, the yield is high, and the commodity properties are good;

[0044] Good: the fungus grows, and there is no obvious difference from the ordinary cultivation bag;

[0045] Middle: the fungus grows, and the hyphae are weak;

[0046] Poor: Growth of aseptic fungi and death of fungi.

[0047] The details are shown in Table 2:

[0048] Table 2 Evaluation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com