Method for preparing ZSM-5 molecular sieve by using solid wastes

A solid waste, ZSM-5 technology, applied in molecular sieve catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of reducing the space utilization rate of molecular sieve synthesis equipment, cannot completely avoid the use of solvents, and is not suitable for large-scale applications. and other problems, to achieve the effect of improving catalytic production efficiency, high crystallinity, and shortening the diffusion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

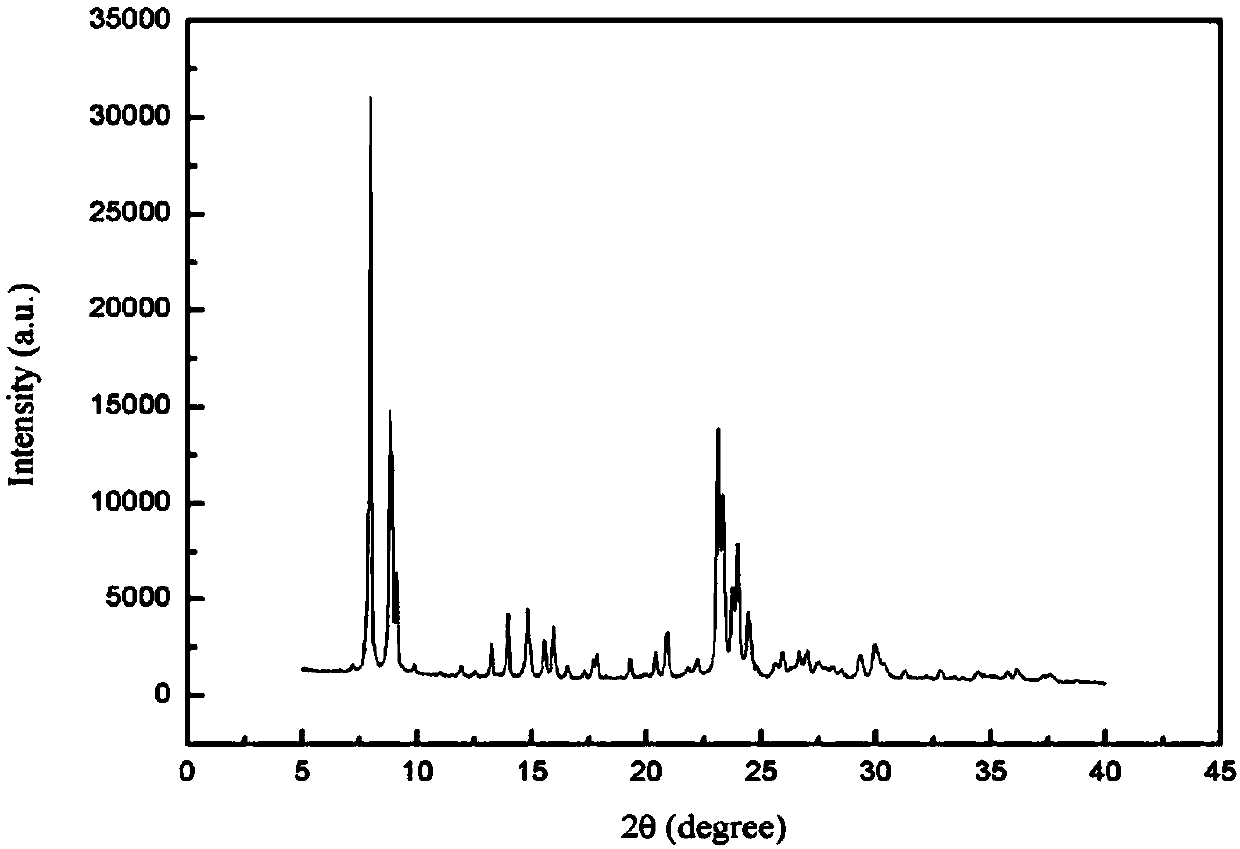

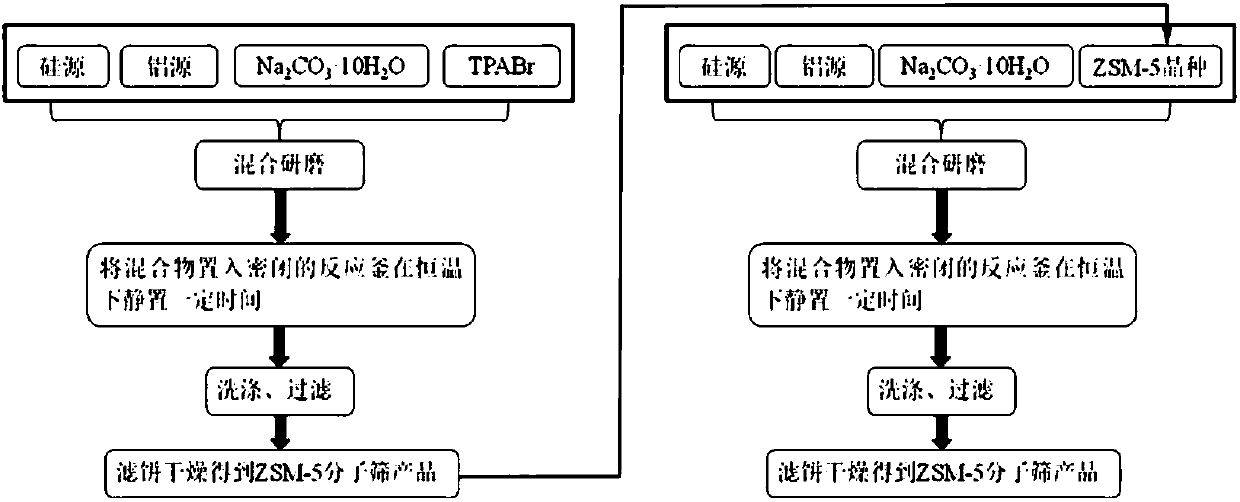

[0034] Take 200 mesh rice husk ash as raw material, take 2g rice husk ash, add 0.2g sodium aluminate, 2.5g Na 2 CO 3 10H 2 O and 0.2g TPABr were placed in a mortar and mixed for 5 minutes, and the mixture was placed in a sealed stainless steel reaction kettle and heated to 100°C for 72 hours of crystallization. After the crystallization is completed, the filter cake is rapidly cooled, washed, and dried to obtain a crystallized product. According to the X-ray diffraction (XRD) test, the product belongs to ZSM-5 molecular sieve. The crystal size of ZSM-5 molecular sieve is 40-200nm. Fe and Mn impurities in the raw materials enter the molecular sieve skeleton. Mesopores. Its XRD phase diagram is shown in figure 1 .

Embodiment 2

[0036] Using iron tailings as raw material, SiO 2 The content is 67%. Take 10g of iron tailings and activate them in a muffle furnace at 500°C for 3 hours, soak the activated product in water for 1 hour, adjust the pH of the filtrate to 9, let it stand for 12 hours, and dry to obtain powder as the raw material for ZSM-5 molecular sieve synthesis. . 2g filter residue, 0.2g sodium aluminate, 2.5g Na 2 CO 3 10H 2 O and 0.2 g of TPABr were placed in a mortar and mixed for 5 minutes, and the mixture was placed in a sealed stainless steel reaction kettle and heated to 100° C. to stand at a constant temperature for 72 hours for crystallization. After the crystallization is completed, the filter cake is rapidly cooled, washed and dried to obtain a crystallized product. The crystal size of ZSM-5 molecular sieve is 40-200nm. Pores and Mesopores. Its XRD phase result is the same as Embodiment 1.

Embodiment 3

[0038] Using iron tailings as raw material, SiO 2 The content is 67%. Take 10g of iron tailings and activate them in a muffle furnace at 500°C for 3 hours, soak the activated product in water for 1 hour, adjust the pH of the filtrate to 9, let it stand for 12 hours, and dry to obtain powder as the raw material for ZSM-5 molecular sieve synthesis. . 2g filter residue, 0.2g sodium aluminate, 2.5g Na 2 CO 3 10H 2 O and Embodiment 1 The obtained ZSM-5 molecular sieve 0.2g was placed in a mortar and ground and mixed for 5 minutes, and the mixture was placed in a sealed stainless steel reaction kettle and heated to 100°C for 72 hours at a constant temperature for crystallization. After the crystallization is completed, the filter cake is rapidly cooled, washed and dried to obtain a crystallized product. The crystal size of ZSM-5 molecular sieve is 40-200nm. Pores and Mesopores. Its XRD phase result is the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com