High repetition frequency fiber laser based on principle of phase offset device and control method

A fiber laser and high repetition frequency technology, applied in lasers, laser components, instruments, etc., can solve the problems of reducing modulation depth, achieve the effect of reducing threshold, increasing repetition frequency and shortening length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

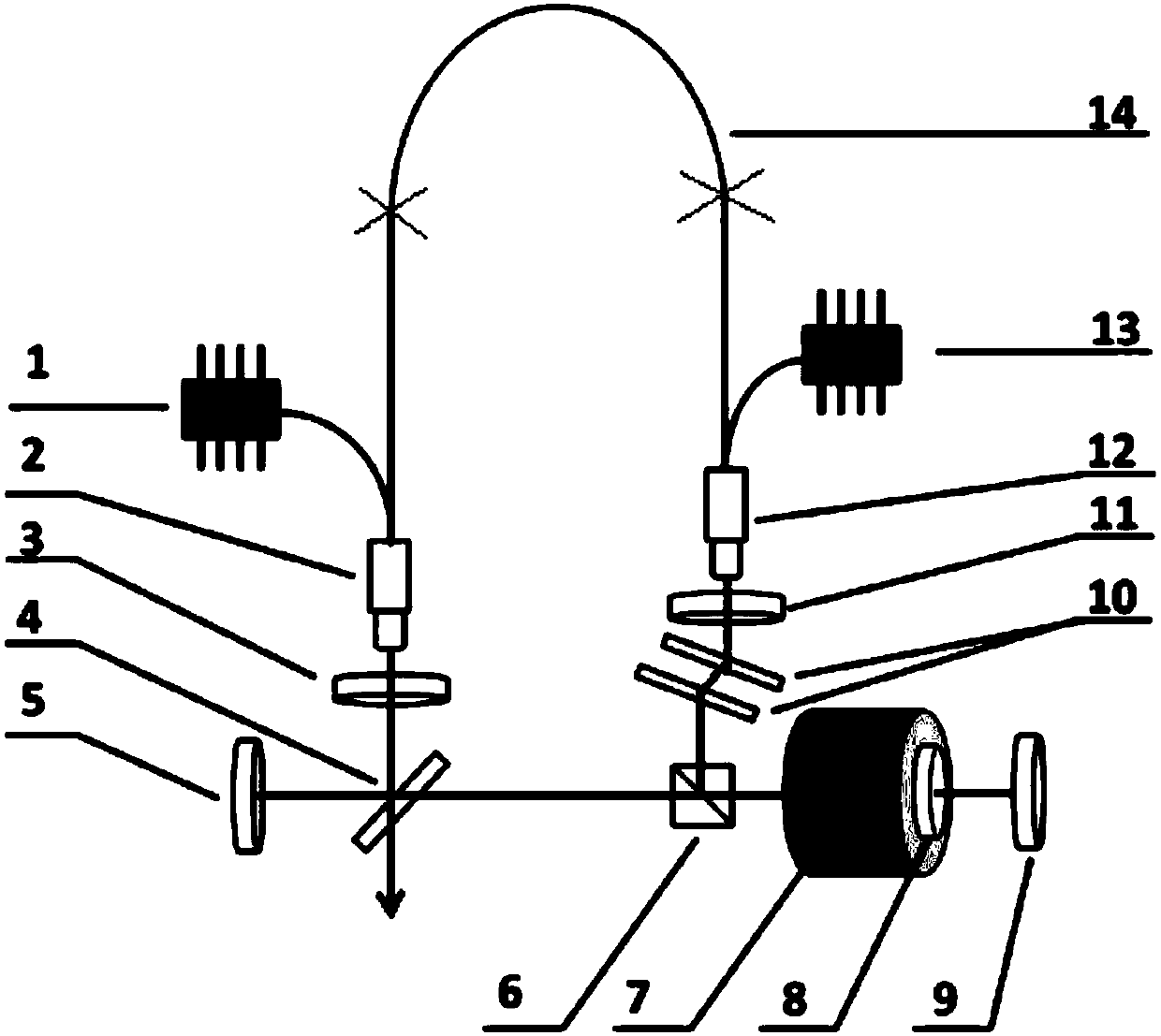

[0030] Such as figure 1 As shown, the high repetition rate fiber laser based on the principle of the phase offset device in this embodiment includes: a first pump source 1, a first wavelength division multiplexing collimator 2, a first half-wave plate 3, a beam splitter Device 4, first mirror 5, polarization beam splitter cube 6, Faraday rotator 7, birefringent crystal 8, second mirror 9, grating pair 10, second half-wave plate 11, second wavelength division complex With collimator 12, the second pumping source 13 and polarization maintaining fiber 14; Wherein, the first pumping source 1 is connected to the tail of the first wavelength division multiplexing collimator 2, and the second pumping source 13 is connected to the first The tail of the two wavelength division multiplexing collimator 12; the tail fiber of the first wavelength division multiplexing collimator 2 and the second wavelength division multiplexing collimator 12 is a gain fiber, connected by a polarization mai...

Embodiment 2

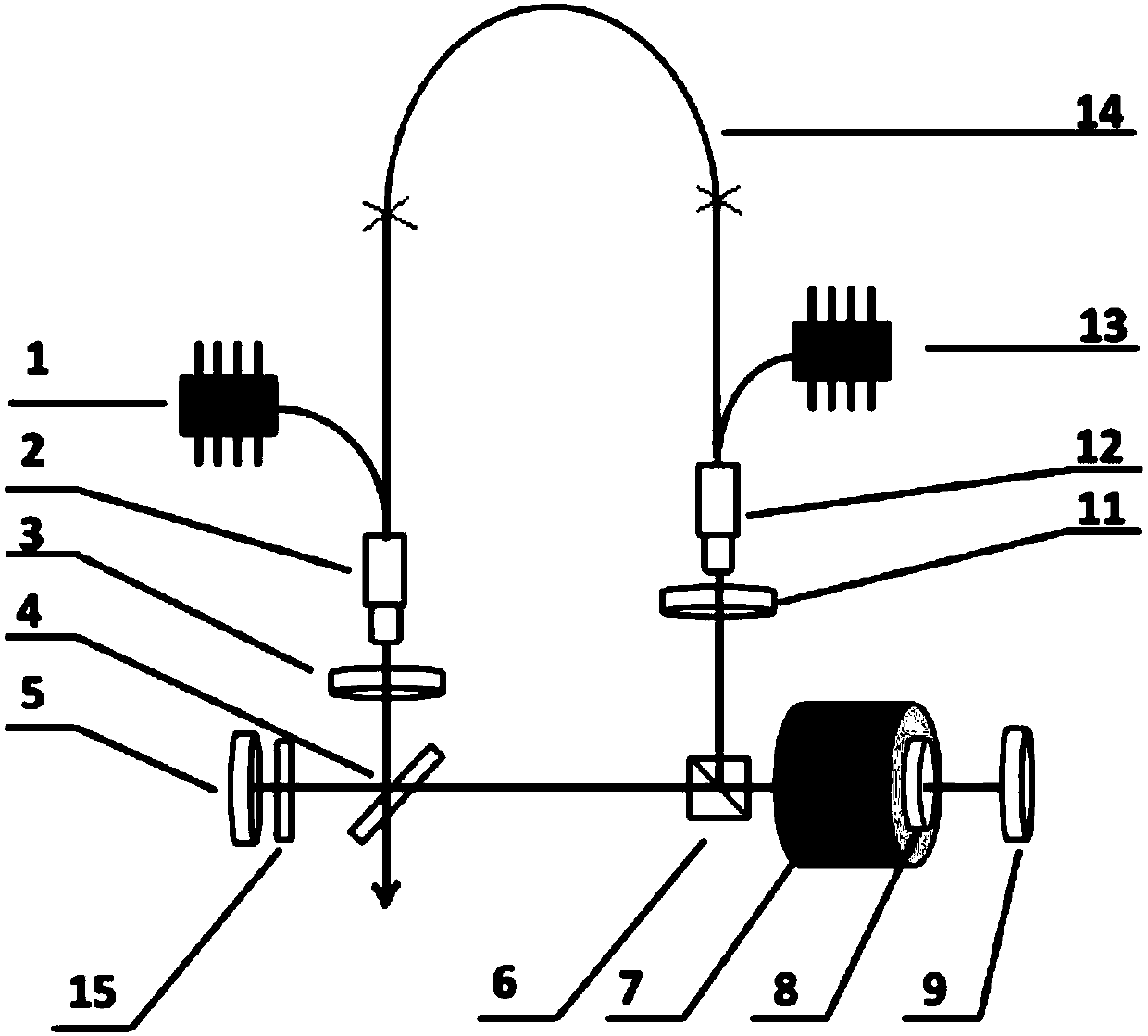

[0033] Such as figure 2 As shown, the high repetition rate fiber laser based on the principle of the phase offset device in this embodiment includes: a first pump source 1, a first wavelength division multiplexing collimator 2, a first half-wave plate 3, a beam splitter Device 4, first mirror 5, polarization beam splitter cube 6, Faraday rotator 7, birefringent crystal 8, second mirror 9, second half-wave plate 11, second wavelength division multiplexing collimator 12. A second pumping source 13, a polarization maintaining fiber 14 and a bandpass filter 15. In this embodiment, a bandwidth control element is used to replace the grating pair, and the bandwidth control element is a filter 15 arranged between the beam splitter and the first reflector to limit the spectrum, and the others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com