Hot melt adhesive film, production method thereof, and automobile door sill

A hot-melt adhesive film and automobile technology, applied in adhesives, vehicle parts, film/sheet adhesives, etc., can solve the problem of high temperature resistance and poor durability, low customer acceptance, and uneven glue distribution and other issues to achieve the effect of high customer acceptance, high customer acceptance, beautiful and reliable products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following examples and this application, the raw materials mentioned are all purchased from the market. Among them, some of the product models are as follows: EAA, Dow 5980; PE-g-MAH Guangzhou Lushan New Material Co., Ltd., VB715; EVA-g-MAH, DuPont C190; Tackifier resin, EASTOTAC H 130; Antioxidant, IRGANOX 1010; coupling agent, KH550.

[0024] 1. Hot melt adhesive film:

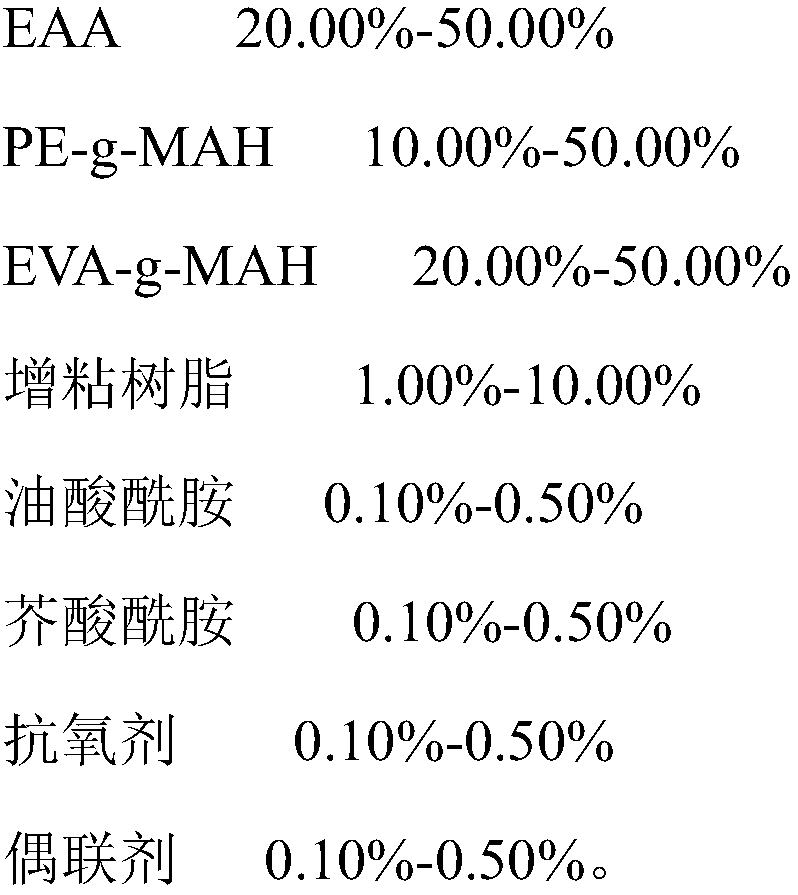

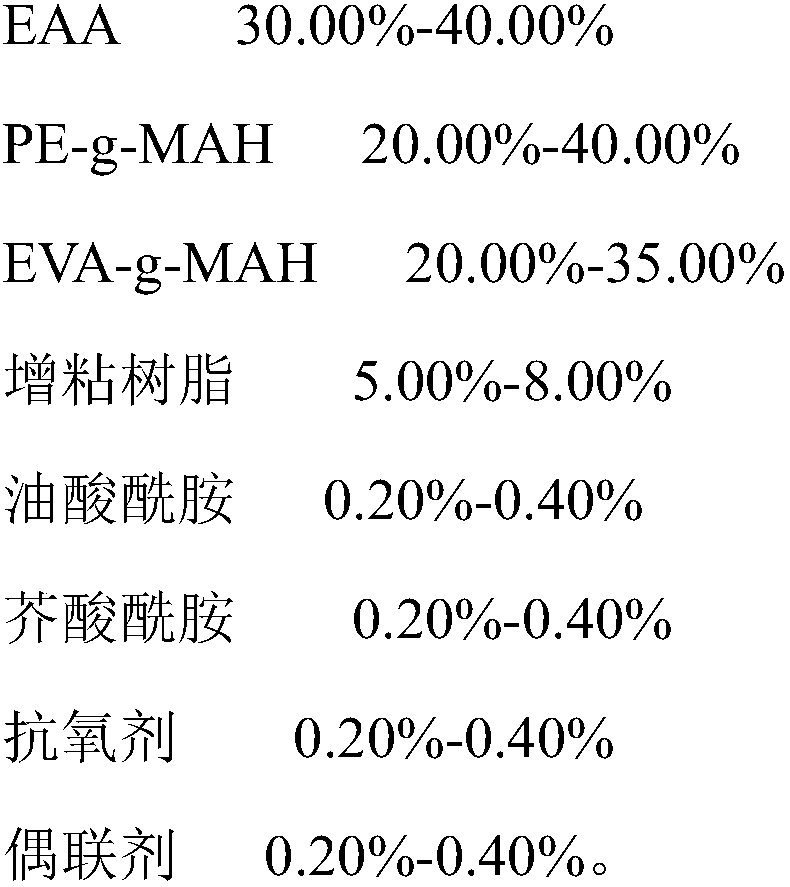

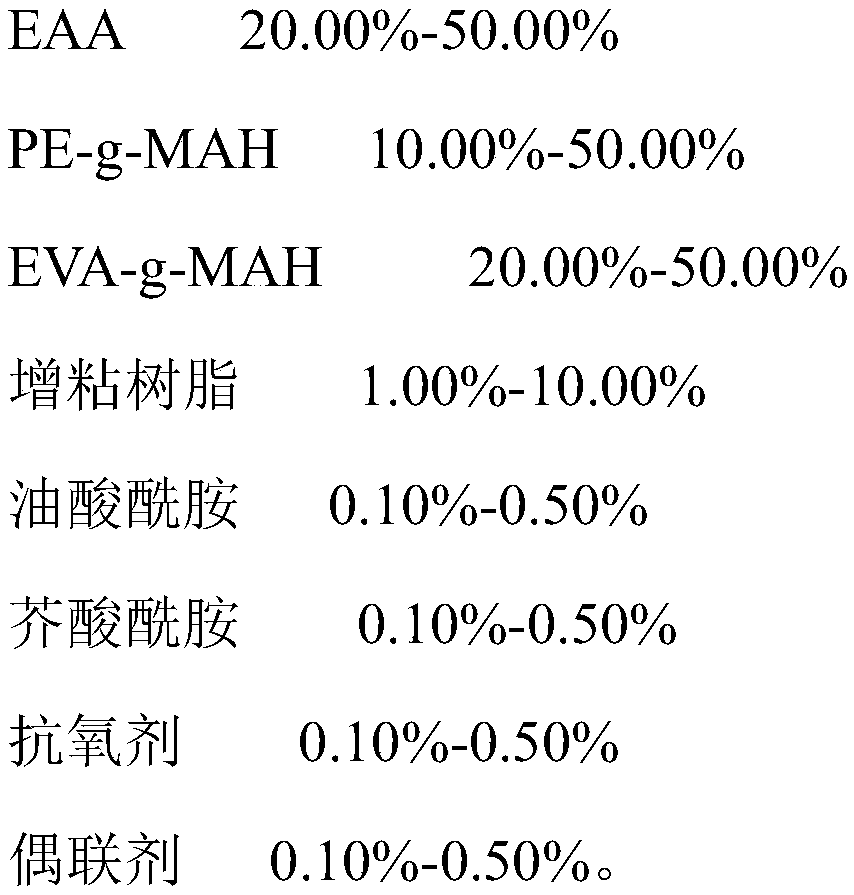

[0025] As shown in Table 1, the composition components of six different hot melt adhesive films of Examples 1-6 are listed. The specific composition components are shown in Table 1, where the proportion of raw materials and auxiliary materials (unit: wt%).

[0026]

[0027] Table 1

[0028] 2. Preparation of hot melt adhesive film:

[0029] (1) According to the material ratio described in Examples 1-6, use a high-speed mixer to fully stir the above-mentioned materials at a speed of 200-800 rpm, stir for 5 minutes, and mix evenly;

[0030] (2) Use a twin-screw granulator to granulate the mixed materials ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com