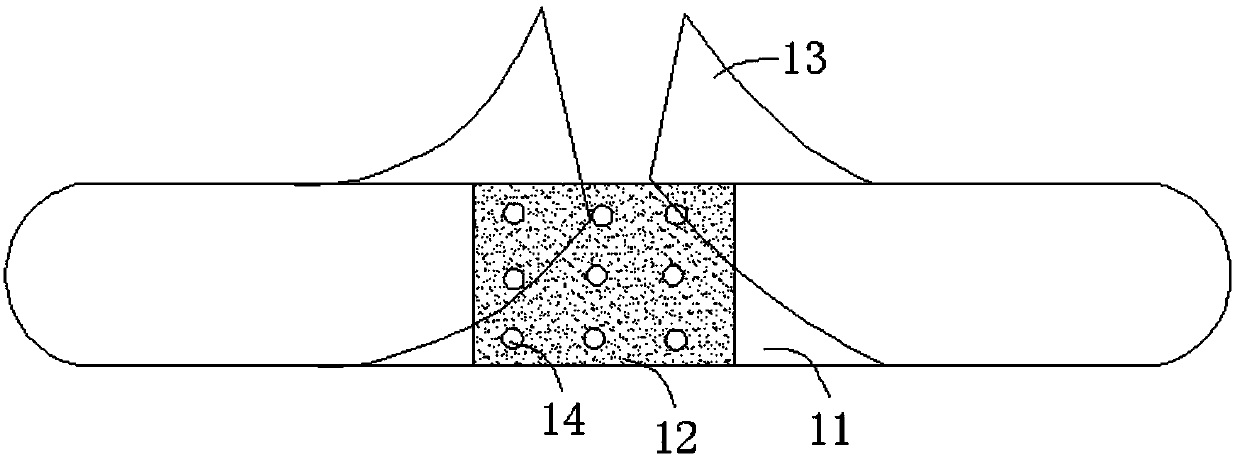

Antibacterial and bactericidal band-aid and preparation method thereof

A band-aid and bactericidal layer technology, which is applied in medical science, textiles and papermaking, fiber treatment, etc., can solve the problems of accelerating bacterial reproduction and no antibacterial effect, and achieves accelerated healing speed, effective antibacterial and bactericidal performance, and good dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

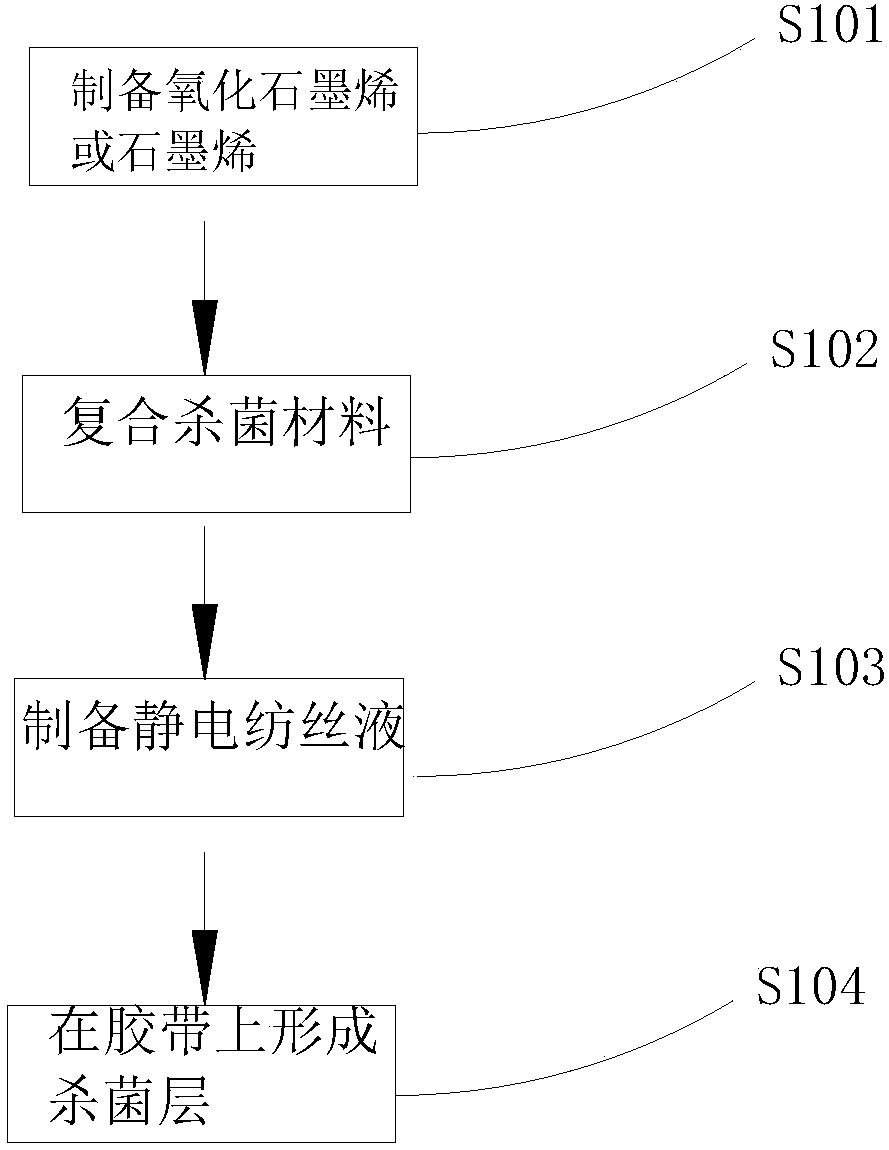

[0024] Such as figure 2 Shown, the present invention also provides the preparation method of bacteriostatic band-aid, comprises the following steps:

[0025] S101, preparing graphene oxide or graphene;

[0026] Graphene oxide preparation methods include:

[0027] Step 1.1, add 2g graphite powder in the flask, add 1gNaNO under ice-water bath 3 and 46mL concentrated sulfuric acid; step 1.2, slowly add 6g of KMnO under magnetic stirring 4 , the temperature is less than 20°C, react for 5-60min and remove the ice-water bath; step 1.3, heat up to 30-40°C, react for 20-60min, slowly add deionized water dropwise; step 1.4, stir for 10-30min and then add 60- 100mL 3wt% hydrogen peroxide solution until the foam in the reaction system disappears; step 1.5, ultracentrifuge at a speed of 7200rpm for 10-30min, and then repeatedly wash with dilute hydrochloric acid and distilled water until the pH is neutral to obtain a crude product; step 1.6, Re-dissolve the obtained crude product in ...

Embodiment 1

[0037] Take the graphene oxide prepared in step S101 with a mass ratio of 1%, add it to ethanol and perform ultrasonication for 30 minutes, continue to add 25% PVA, and continue ultrasonication for 2 hours, so that PVA and graphene oxide are fully and uniformly mixed to form a uniform spinning solution The spinning solution is transferred to the syringe of the spinneret, the metal needle diameter of the syringe is 2mm, the positive pole of the high voltage power supply is connected to the metal needle, the scotch tape is grounded, the distance from the metal needle of the syringe to the scotch tape is 12cm, and the flow rate is 0.2mL / h. Under the environment of humidity 50%RH and temperature 25°C, the two-pole voltage is adjusted to 15KV for spinning, and finally a bacteriostatic layer is directly formed on the scotch tape.

Embodiment 2

[0039] Take the graphene prepared in step S101 with a mass ratio of 5%, add it to ethanol and perform ultrasonication for 30 minutes, continue to add 25% polyvinylpyrrolidone, and continue ultrasonication for 2 hours, so that the polyvinylpyrrolidone and graphene oxide are fully and uniformly mixed to form Uniform spinning solution; the spinning solution is transferred to the syringe of the spinneret, the diameter of the metal needle of the syringe is 2mm, the positive pole of the high-voltage power supply is connected to the metal needle, the scotch tape is grounded, the distance from the metal needle of the syringe to the scotch tape is 12cm, and the flow rate is 0.2mL / h, in an environment with a humidity of 50%RH and a temperature of 25°C, adjust the bipolar voltage to 15KV for spinning, and finally form an antibacterial layer directly on the scotch tape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com