an embedded tio 2 hollow ball/gan/ga 2 o 3 Heterojunction photocatalytic thin film and preparation method thereof

A photocatalytic thin film and hollow sphere technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as limiting photocatalytic activity, and achieve improved photocatalytic efficiency, avoiding recombination, and high efficiency. separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

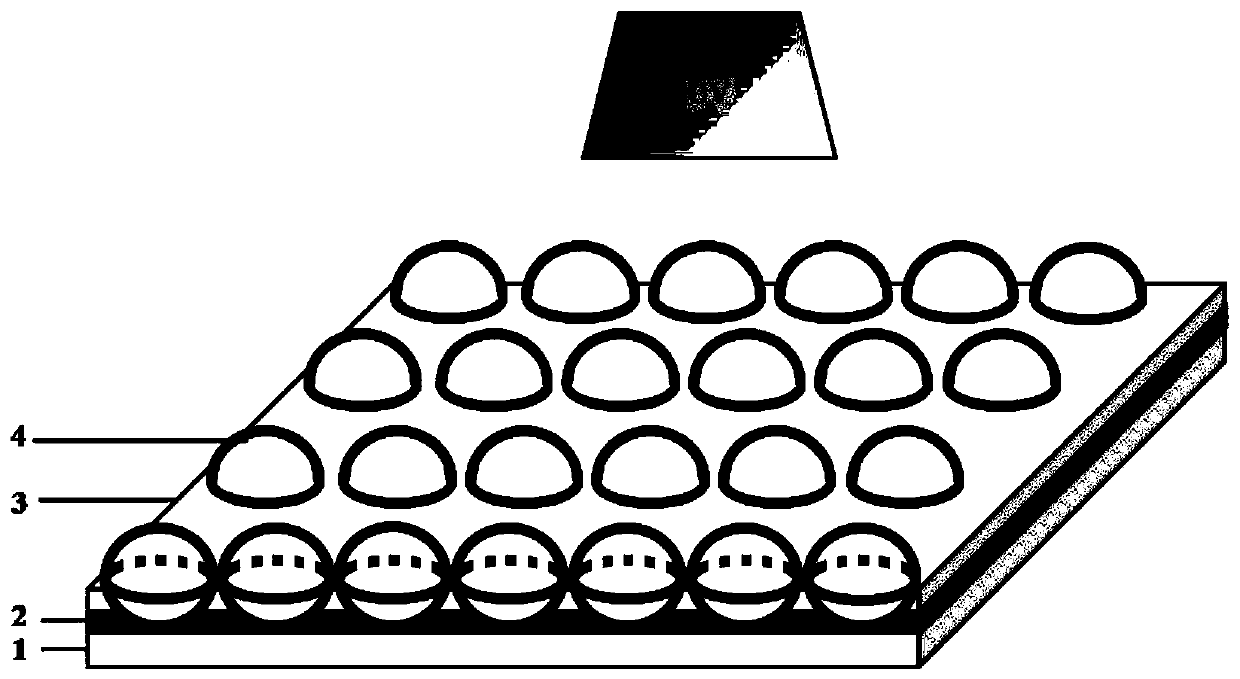

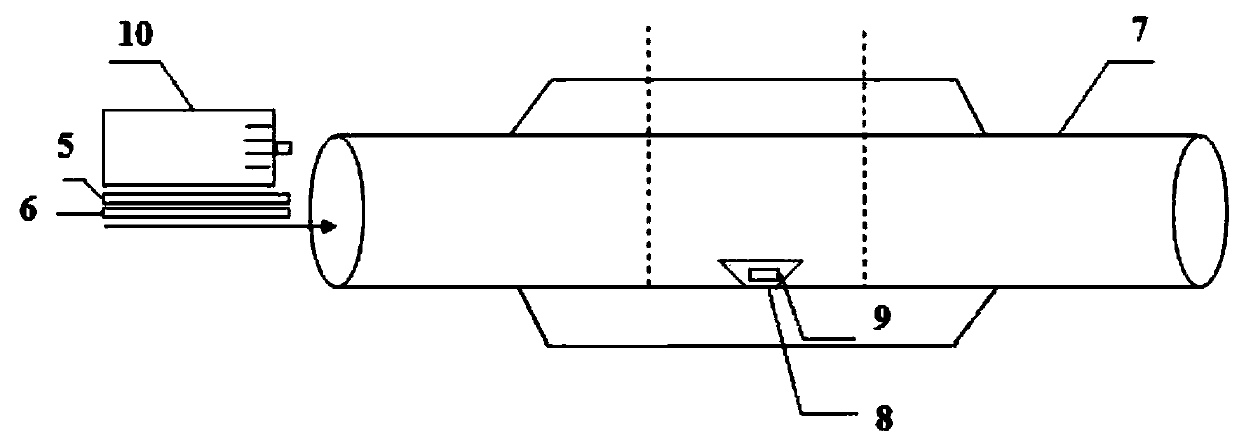

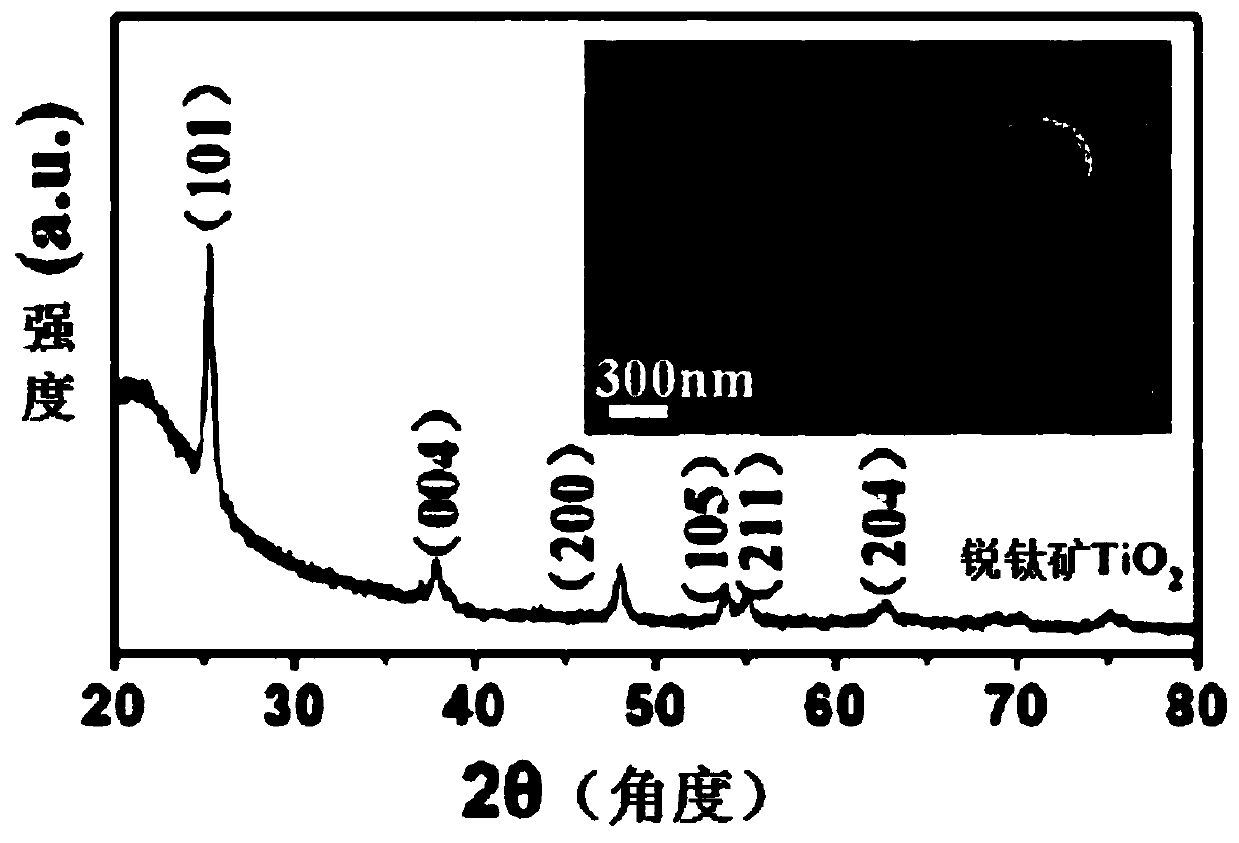

[0038] Embedded TiO 2 Hollow sphere / GaN / Ga 2 o 3 A method for preparing a heterojunction photocatalytic thin film, comprising the following steps:

[0039] Step 1, ITO transparent conductive glass pretreatment: ultrasonic cleaning with acetone, absolute ethanol, and deionized water respectively, and vacuum drying;

[0040] Step 2, SiO 2 Preparation of microspheres: Measure 1mL tetraethyl orthosilicate and 10mL absolute ethanol and stir evenly at room temperature; measure 2mL deionized water, 8mL absolute ethanol and 1mL ammonia water and stir evenly at room temperature; Mix and stir at 40°C for 2 hours to obtain SiO 2 Microsphere sol, cleaned with anhydrous ethanol and deionized water ultrasonic circulation to obtain SiO with a particle size of 300-500nm 2 Microspheres;

[0041] Step 3, SiO 2 @TiO 2 Preparation of core-shell microspheres: Measure 1mL tetrabutyl titanate and 80mL absolute ethanol, seal and stir evenly at room temperature; take the SiO prepared in step 2...

Embodiment 2

[0048] An embedded TiO 2 Hollow sphere / GaN / Ga 2 o 3 A method for preparing a heterojunction photocatalytic thin film, comprising the following steps:

[0049] Step 1, ITO transparent conductive glass pretreatment: ultrasonic cleaning with acetone, absolute ethanol, and deionized water respectively, and vacuum drying;

[0050] Step 2, SiO 2 Preparation of microspheres: Measure 1mL tetraethyl orthosilicate and 10mL absolute ethanol and stir evenly at room temperature; measure 2mL deionized water, 8mL absolute ethanol and 1mL ammonia water and stir evenly at room temperature; Mix and stir at 40°C for 2 hours to obtain SiO 2 Microsphere sol, cleaned with anhydrous ethanol and deionized water ultrasonic circulation to obtain SiO with a particle size of 300-500nm 2 Microspheres;

[0051] Step 3, SiO 2 @TiO 2 Preparation of core-shell microspheres: Measure 1mL tetrabutyl titanate and 80mL absolute ethanol, seal and stir evenly at room temperature; take the SiO prepared in ste...

Embodiment 3

[0056] An embedded TiO 2 Hollow sphere / GaN / Ga 2 o 3 A method for preparing a heterojunction photocatalytic thin film, comprising the following steps:

[0057] Step 1, ITO transparent conductive glass pretreatment: ultrasonic cleaning with acetone, absolute ethanol, and deionized water respectively, and vacuum drying;

[0058] Step 2, SiO 2 Preparation of microspheres: Measure 1mL tetraethyl orthosilicate and 10mL absolute ethanol and stir evenly at room temperature; measure 2mL deionized water, 8mL absolute ethanol and 1mL ammonia water and stir evenly at room temperature; Mix and stir at 40°C for 2 hours to obtain SiO 2 Microsphere sol, cleaned with anhydrous ethanol and deionized water ultrasonic circulation to obtain SiO with a particle size of 300-500nm 2 Microspheres;

[0059] Step 3, SiO 2 @TiO 2 Preparation of core-shell microspheres: Measure 1mL tetrabutyl titanate and 80mL absolute ethanol, seal and stir evenly at room temperature; take the SiO prepared in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com