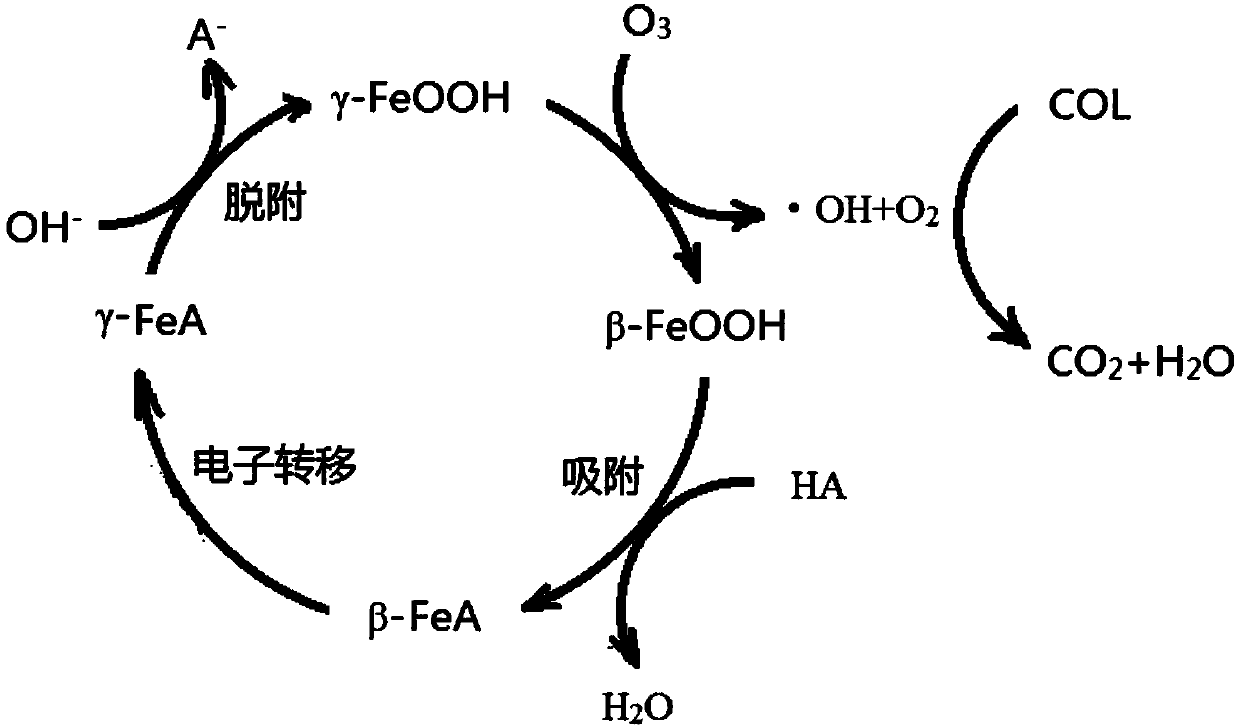

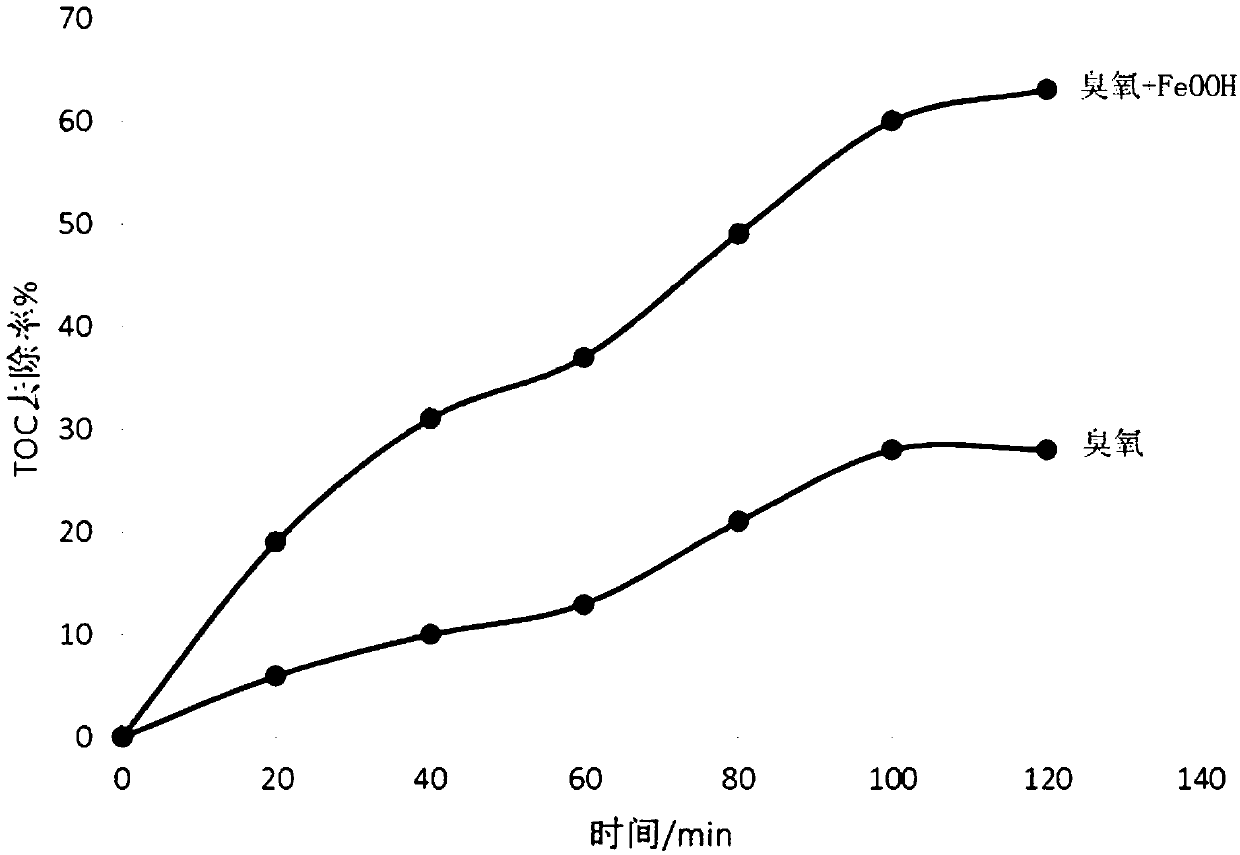

Method for breaking colloid of fracturing flow-back liquid based on gamma-hydroxyl iron oxide catalytic ozone advanced oxidation system

An iron oxyhydroxide, fracturing flowback fluid technology, applied in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc., can solve the problem of high operating cost, unsatisfactory treatment effect, macromolecular colloid and organic Insufficient degradation and other problems, to achieve the effect of fast breaking speed, increasing contact area and time, and large porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Gel breaking treatment of fracturing flowback fluid in Zhuoye 1 Well, Qianjiang, Chongqing

[0025] The total amount of fracturing flowback fluid produced by Zhuoye 1 well in Qianjiang, Chongqing totaled 19,000m 3 . The water quality is complex, the viscosity is high, the treatment is difficult, and the emulsification degree is high, the COD is high, the salinity is high, and the stability is high. Due to the difficulty of processing, the reaction residence time and the proportion of ozone dosing should be appropriately increased.

[0026] The treatment process and parameters of the advanced ozone oxidation system catalyzed by γ-iron oxyhydroxide are as follows:

[0027] (1) Preparation of γ-iron oxyhydroxide catalyst: Iron filings are dissolved with acid to control the pH to 1.5, and the H to be added is calculated according to the concentration of ferrous ions 2 o 2 The amount of iron filing acid solution in the control of ferrous ion concentration Fe ...

Embodiment 2

[0033] Example 2: Changning H 4 Platform fracturing flowback fluid treatment

[0034] Changning H 4 The total amount of fracturing flowback fluid wastewater generated by the platform has accumulated to 6000m 3 . Ca in the fracturing flowback fluid 2+ , Mg 2+ And the TDS content is high, the viscosity is relatively small, and the processing difficulty is moderate, so the reaction residence time can be appropriately shortened and the ozone dosing ratio can be reduced.

[0035] The treatment process and parameters of the advanced ozone oxidation system catalyzed by γ-iron oxyhydroxide are as follows:

[0036] (1) Preparation of γ-iron oxyhydroxide catalyst: Iron filings are dissolved with acid to control the pH to 1.5, and the H to be added is calculated according to the concentration of ferrous ions 2 o 2 The amount of iron filing acid solution in the control of ferrous ion concentration Fe 2+ with H 2 o 2 The ratio is 1:1.0, stirring and reacting for 30 minutes, addin...

Embodiment 3

[0042] Example 3: Treatment of fracturing flowback fluid in Well Dazu 201

[0043] The total amount of fracturing flowback fluid wastewater produced by Well Dazu 201 totaled 2000m 3 . Fracturing flowback fluid wastewater has high COD and SS, high salinity, strong stability, high viscosity, and complex water quality, which is difficult to treat.

[0044] The treatment process and parameters of the advanced ozone oxidation system catalyzed by γ-iron oxyhydroxide are as follows:

[0045] (1) Preparation of γ-iron oxyhydroxide catalyst: Iron filings are dissolved with acid to control the pH to 1.2, and the H to be added is calculated according to the concentration of ferrous ions 2 o 2 The amount of iron filing acid solution in the control of ferrous ion concentration Fe 2+ with H 2 o 2 The ratio is 1:1, stirring and reacting for 30 minutes, adding NaOH continuously and uniformly for 2 hours, finally controlling the pH to 4.5, controlling the temperature below 24°C, inoculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com