Composite material for preparing table tennis ball and preparation method thereof

A composite material and table tennis technology, applied in the field of table tennis production, new plastic table tennis materials and their preparation, can solve the problems of inflammability and explosion, environmental hazards, complicated table tennis production process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] As a preferred embodiment, the components and parts by mass of the compatibilizer are further optimized as follows: 91-97 parts of the second AS resin, 2-6 parts of comonomer, glycidyl methacrylate (MA) 1 -3 parts, initiator 0.1-0.3 parts, second stabilizer 0.1-0.4. Its preparation method comprises the following steps:

[0026] (1) Weigh each component according to the proportion, place it in a high mixer and stir for 5-10 minutes to obtain mixture A;

[0027] (2) Put the mixture A in a twin-screw machine, melt and extrude, and granulate. The zone temperature is 180-200°C, the fifth zone temperature is 180-200°C, the head temperature is 210-230°C, the barrel residence time is 1-3 minutes, and the melt pressure is 10-20MPa.

[0028] The glycidyl methacrylate is a strong polar reactive group, and is a polymer interface coupling agent, a compatibilizer, and a dispersion accelerator, so that the material has high polarity and reactivity, and can also improve compatibilit...

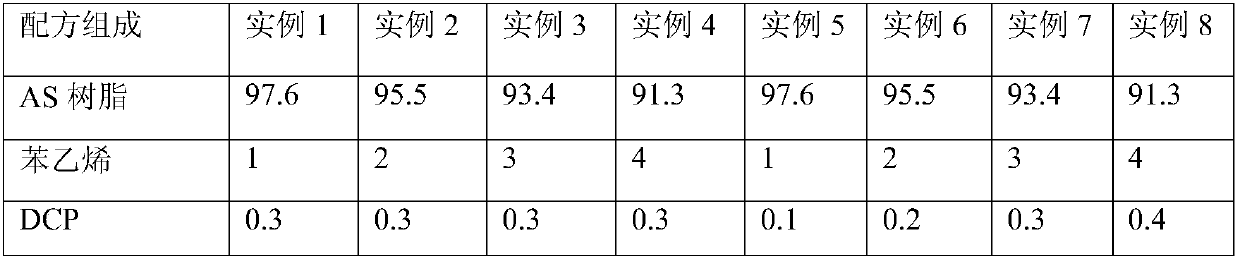

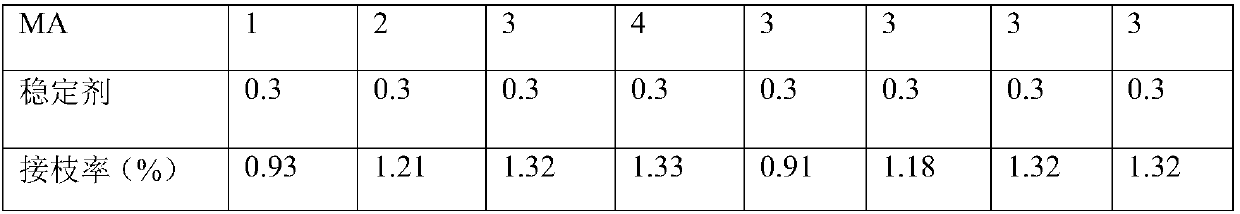

Embodiment 1-4

[0035] Prepare the compatibilizer maleic anhydride grafted polyketone according to the components and parts by mass in Table 1. The preparation method is: (1) weigh each component according to the proportion, place it in a high mixer and stir for 8 minutes to obtain the mixture;

[0036](2) Place the mixture obtained in step (1) in a twin-screw machine, melt and extrude, and granulate. 180-200°C, the temperature of the fourth zone is 160-180°C, the temperature of the fifth zone is 160-180°C, the temperature of the die head is 190-210°C, the residence time of the barrel is 1-3 minutes, and the melt pressure is 10-20MPa.

[0037] Table 1. The formula component of compatibilizer in embodiment 1-8 and the grafting rate of the compatibilizer that prepares

[0038]

[0039]

[0040] Glycidyl methacrylate MA grafted AS compatibilizer was obtained through the above steps, and the grafting rate of Example 4 was the highest. The results showed that the grafting rate of glycidyl m...

Embodiment 9-12

[0042] Adopt the component formula shown in table 2 (all are mass ratio) to be used for preparing table tennis composite material, wherein the compatibilizer of embodiment 5-8 and comparative example 2-4 adopts the phase that above-mentioned embodiment 3 obtains Toner. The preparation method is as follows: weigh each component according to the proportion; mix the compatibilizer, lubricant and stabilizer evenly, mix the other components evenly, and add them to the twin-screw extruder in different areas at the same time to extrude, after water cooling, pelletizing , to produce a nylon / polyketone alloy material with excellent performance. Among them, the temperature of the twin-screw extruder from the feed section to the machine head is as follows: the temperature of the first zone is 160°C-180°C, the temperature of the second zone is 200°C-230°C, the temperature of the third zone is 200°C-230°C, and the temperature of the fourth zone is 200°C. ℃-230℃, the temperature of the fif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com